The consumer-driven retail furniture manufacturing market grapples with the need to accommodate fluctuating volumes, manage scarce labor strength and cope with rising infrastructural costs. Offshoring your CAD requirements ensures flexibility, scalability and optimized costs while promising quality designs.

info@truecadd.com

How Outsourcing CAD Drafting Improves Efficiency for Retail Furniture Manufacturers

Challenges of mass-customization are forcing retail furniture manufacturers to rethink their design-to-manufacturing workflows to stay more flexible and optimized. Outsourcing CAD drafting to offshore companies give them this flexibility along with cost benefits.

Table of Contents

Retail stores often have very customized and layout specific furniture. To offer greater variety and personalization and ensure cost reduction, retail store fit-out manufacturers look for CAD design drafting partners to reduce engineering lead time.

Challenges faced by retail store furniture manufacturers

The current situation of the retail furniture industry throws up challenges for manufacturers that include:

- Limited design flexibility due to slower response times and difficulties in iterating designs without in-house expertise.

- Concerns about quality control arise as oversight over the drafting process diminishes when outsourcing CAD services.

- Lack of customization may result in generic designs that fail to meet customer expectations and market demands.

- On time delivery can be a huge challenge to manage when the demand suddenly rises or falls.

All these challenges demand the need of a skilled, reliable and flexible CAD resources to manufacture cost-optimized furniture. Outsourcing of CAD drafting to offshore teams has proven to be a winning formula in facing these challenges.

How outsourcing CAD drafting helps retail furniture manufacturers

Flexible working methods of offshore CAD drafting teams

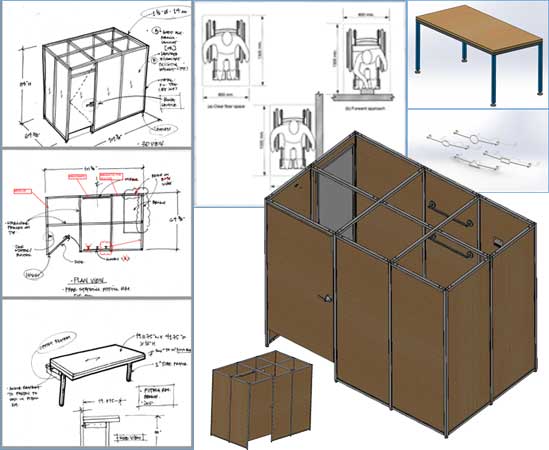

Turnaround times for customized furniture are tighter than mass production. Responding to customer inquiries with sales information, getting design approvals, and delivering the product on time requires flexible infrastructure.

This is where offshore CAD drafting teams come into the picture. They can create drawings, customize the models, generate supporting documents, and manage revisions. Their services make time for your in-house team to create new designs, innovation and research, focus on sales, and enhance client communication. Offshore teams comfortably manage revisions as they are structured to accommodate any number of iterations to meet quality benchmarks.

Offshore CAD drafting delivered detail CAD furniture drawings in 72 hours

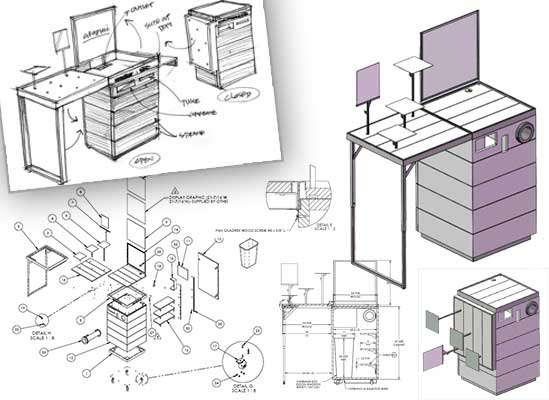

TrueCADD teams, while working with a retail furniture manufacturer delivered detailed drawings and 3D models in SolidWorks within 72 hours. Project engineers gained in-depth understanding of design intent from conceptual sketches and created drawings as per regional standards.

The project team was split to work in multiple shifts including night times. This helped them leverage the time zone difference between the client’s location in the Netherlands and India. At the end of the project, the furniture manufacturer realized 50% reduced cost and time because of offshore partnership.

Scalability and easy ramp-up for on-time delivery

Furniture manufacturers often run their operations based on the contracts they receive. So, their workloads fluctuate often, but the team size stays the same. It either leads to delays in delivery or the manufacturing company has to let go lucrative projects.

Outsourcing CAD drafting work in part or full helps to address scalability. By collaborating with an expert CAD outsourcing team, furniture manufacturers can hire CAD drafting resources when needed. As the workload decreases, the extra resources can be put on the bench until new work arrives.

With easy scalability of team size furniture, companies can:

- Save extra costs in the form of salary paid to benched resources

- Take up any project without worrying about resource availability

- Avoid mass hiring and firing

- Cut down on extra administrative expenses or investments for staff and infrastructure

- Reduce the need for hiring specialists and recruitment hassles

Controlling the expenditure on furniture CAD drafting

Furniture manufacturing firms spend heavily on acquiring technology, skilled resources, and infrastructure. For instance, to create CAD drawings for furniture manufacturing shop floor, manufacturers acquire dedicated CAD tools. The firm would purchase licenses for 2020 Design for kitchen cabinet projects and SWOOD for another woodworking project. Similarly, it would hire engineers proficient in using these platforms for faster TAT. But when the projects are over, the licenses are of no use until another similar project comes up.

Alternatively, by collaborating with an offshore CAD drafting company, furniture manufacturers get access to:

- High-end computers with the latest OS to work with rendered furniture models

- Multiple licenses for various CAD programs specific for wood and metal

- Provisions for design automation for specific furniture product-mix

- Highly qualified engineers for seamless design development

These facilities offered by the CAD outsourcing firm save the manufacturing company from additional expenses. Secondly, outsourcing firms charge fees per project. Hence, they offer cost-effective CAD solutions. Additionally, when offshoring a major part of design work, costs inevitably come down. This helps control the overall cost of furniture per product.

Offshore CAD teams reduced 60% design costs using SolidWorks

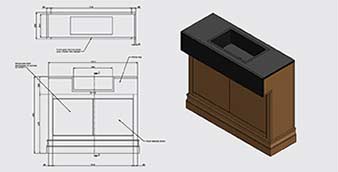

TrueCADD’s SolidWorks experts transformed hand sketches into final manufacturing drawings for a retail furniture store in the UK.

The team followed a knock-down design approach which saved transportation costs by 45%. The outsourcing model further reduced the design costs by 60%.

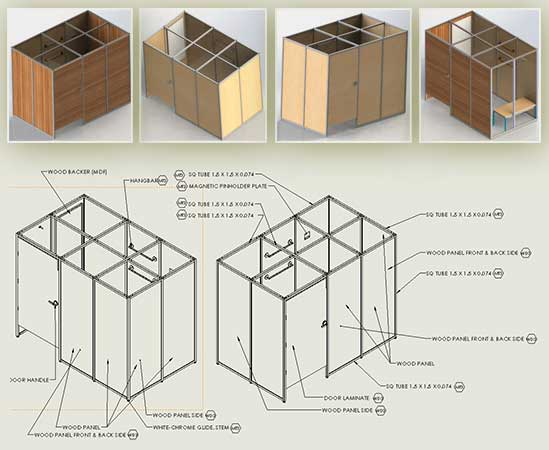

Teams with different specializations for quality furniture drawings

We can categorize the entire furniture market into different verticals as per usage and needs. For example, residential furniture is further segmented into living room furniture, kitchen furniture and cabinets, patio, and garden furniture and so and so forth. Again, in garden furniture, the ones used in public parks and in-home gardens, or patios, are different.

All the products follow specific standards, which again change from region to region. In the UK, the manufacturers follow BIFMA while in the USA they have ANSI or AWI for wooden furniture drawings. A designer needs to know these specifications for every industry.

CAD outsourcing firm, like TrueCADD, has teams dedicated to your project. Outsourcing 2D & 3D CAD drafting to these teams gives you an edge in creating accurate furniture products over in-house team.

Some resource advantages offshore CAD drafting firms offer, include:

- Specific teams with expertise in SolidWorks, AutoCAD®, Inventor®, etc.

- The choice to build a needs-based team for your projects.

- Sheet metal design experts, wooden furniture experts, etc. to take care of detailed furniture shop drawings for every project.

- Senior engineers who check the quality of every manufacturing drawing, BOMs, other documents like DXFs, etc.

- Long-standing industry experience to find errors during early stages.

- Keep up with upcoming industry trends to stay ahead in competitive market.

- Extended design teams who collaborate closely with your design engineers and shop engineers.

You get access to domain experts, CAD specialists and other specialized resources to increase overall quality and reduce costs.

How furniture manufacturers can stay lean with CAD outsourcing

With a customer-driven market base retail furniture manufacturer need to cut expenses, ensure quality deliverables and adhere to timelines. Outsourcing of furniture CAD drafting essentially takes care of these aspects because of their teams’ flexibility, scalability, and experience.

Outsourcing CAD drafting companies also quickly develop automation of processes, work inflow, and work assignments. It enhances robust and clear communication between the client and the outsourcing company. By maintaining a two-way communication process across the project lifecycle, outsourcing is set to help furniture manufacturers stay profitable.

Enhance furniture manufacturing efficiencies with an expert offshore CAD teams

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.