info@truecadd.com

Improve construction processes with precast concrete detailing & modeling

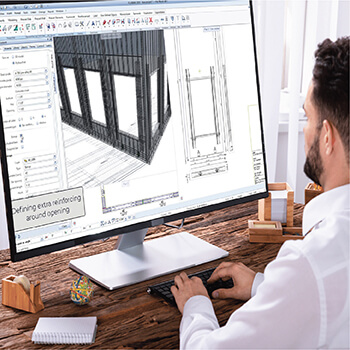

TrueCADD specializes in customized precast concrete detailing and structural concrete modeling through preemptive 3D BIM modeling reinforced by Revit®, BIM 360® and Navisworks®. We specialize in converting 2D drawings into a coordinated and clash-free 3D model with a comprehensive data set to understand overall construction, adhere to building standards, minimize waste, and speed up construction.

Structural precast detailing services at TrueCADD are driven to envision project structure, build detailed models, and generate coordinated layouts with concrete shop drawings for contractors, engineering consultants, precast manufacturers, structural engineers, and other stakeholders. Our team offers concrete preconstruction modeling, formwork modeling and prefab/precast concrete detailing to facilitate hassle-free documentation, understand end-to-end processes, and reduce production time.

Outsource your structural concrete modeling requirements to us →

Concrete modeling reinforced with automation to speed up construction

Our software and file interoperability capabilities enable us to accept various client inputs for 3D Formwork modeling, precast detailing, precast panel detailing, etc. in Revit®, BIM 360®, and Navisworks®. Our 3D models reinforced with BIM automation tools like Dynamo help you analyze project requirements and overall timelines scheduled to gain better project clarity. We provide top-notch concrete preconstruction modeling, formwork, concrete shop drawings, and precast detailing services for various sectors such as commercial, residential, civil & infrastructure, bridges, architectural, skyscrapers, bridges, etc.

Our structural precast concrete detailing services include:

- Produce rebar models, modular construction models, and framing prefabrication models.

- Accurate Revit-based precast element modeling for beams, columns, hollow and solid slabs façade concrete walls, etc.

- Prepare information-rich concrete mould and precast shop drawings, and erection drawings with erection identifiers for structural members and various rebar types.

- Generate and analyze connection details for element assemblies.

- Develop 3D model-based precise BOQs and BOMs for various concrete grades and element types such as M20 to M75.

- Formulate Bar Bending Schedules for various bars with data enrichment for dimensions and quantities.

- In-depth interdisciplinary coordination and clash detection and resolution.

- Precise Formwork modeling, detailing and Boxouts, and other structural engineering solutions.

Advantages of structural concrete modeling & detailing

-

Clash-free designs

Preemptive clash detection and resolution in the preconstruction stage cancels out costly rework as well as project delays.

-

Coordinated 3D models

Highly coordinated 3D BIM models reinforced by automation to save production time, reduce material waste, and diminish costs.

-

Hassle-free installation

3D visualization with accurate structural detailing document set for precasters & contractors to mitigate onsite clashes for error-free installation.

-

Greater constructability

3D modeling for precast elements to improve fabrication, assembly, and onsite installation through consistent and quality data.

-

Team collaboration

Establish team communication and collaboration between onsite as well as offsite teams for information sharing through BIM 360.

-

Enhanced schedules & material estimation

3D models reinforced with 4D scheduling and 5D cost estimation, and detailed BOQ’s accelerate project schedules and improve material estimates.

What our Clients Say

– Project Manager Pre-cast Manufacturing Company, Netherlands

Our Customers

Why you should outsource your precast concrete detailing projects to us

- Drive Revit model-based detailing to enhance overall reliability and quality.

- Build fabrication-ready models and drawings for improved fabrication and installation.

- Customized structural concrete detailing using parametric Revit families for greater element quality and consistency.

- Enhance project schedules with model-extracted drawing sheets and 3D presentation views enriched with preemptive QC.

- Comprehensive project erection simulation with IFC BIM models.

- Feasibility study of concrete detailing layouts through sustainability, stability, BOQ, and concrete assumptions.

- Project reviews and feedback for perpetual improvement and quality management.

- Management of project changes and dynamic updates of various assemblies.

- Accurate precast detailing in 3D geometry for effective cost calculation and material estimation.

- Clear communication between trades at every building phase.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.