info@truecadd.com

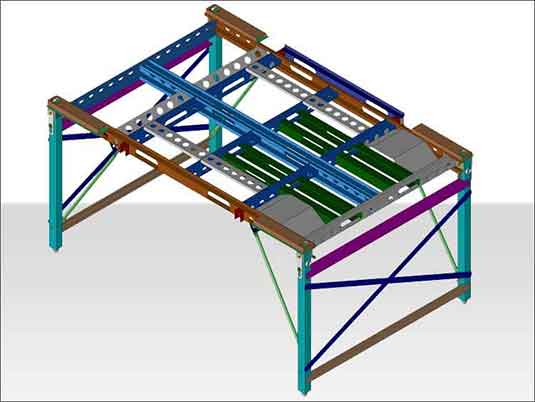

Accurate sheet metal CAD drawings for precise fabrication

Fabricators regularly experience shop floor delays and material waste when engineering data lacks manufacturability, bend allowances are inaccurate or flat patterns have errors. TrueCADD’s sheet metal design services ensure faster production and reduced errors by validating designs against your tooling and shouldering the drafting load.

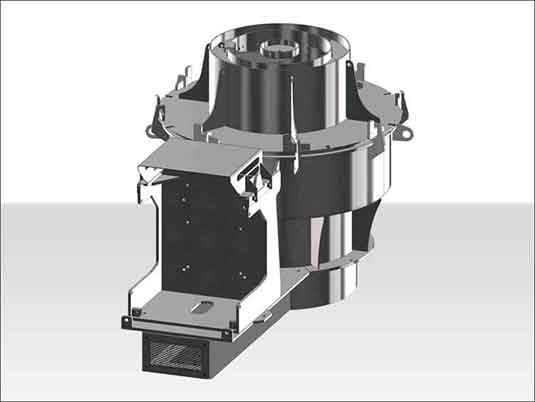

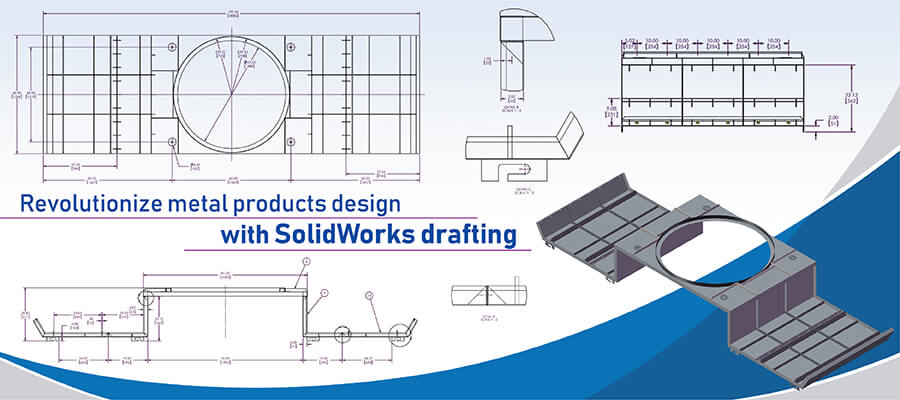

We deliver accurate sheet metal 2D drawings as well as annotated SolidWorks sheet metal modeling for both design and manufacturing, providing the data you need for logistics and optimization. This includes detailed sheet metal manufacturing drawings including nesting reports, Bill of Material (BoM), cut and shear lists, etc. for multiple types of sheet metals and alloys to assist you in your fabrication.

Expert sheet metal modeling services for precision fabrication

We create your sheet metal fabrication drawings to match the capabilities of your machine shop. And we provide you the geometric dimensions and tolerancing for all drawings. We work closely with sheet metal contractors, door design and window manufacturers and all custom metal product manufacturers to create for them the best sheet metal designs and 3D CAD models. We use industry leading sheet metal design software like SolidWorks for designs that help in high quality fabrication.

Our sheet metal design and drafting services include:

We create a full range of product development and fabrication documents from an initial 3D model to the final product fabrication drawings compliant with the applicable ANSI, ASME, TEMA, BS drawing standards.

Comprehensive nesting reports and documentation

We provide detailed nesting reports with DXF files, sheet metal part drawings and clear assembly and installation instructions so you can get the most out of your manufacturing process.

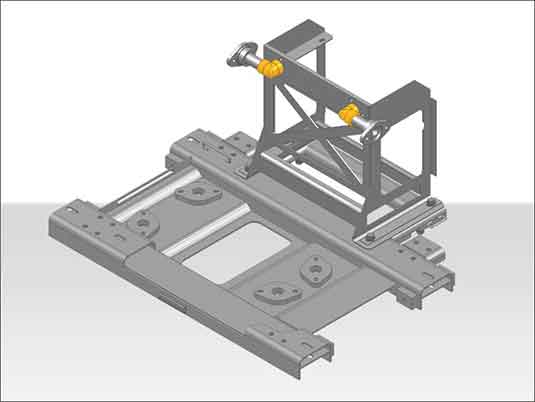

Fabrication-ready sheet metal drawings

Our designers will prepare accurate drawings for the various fabrication processes, such as bending, boring, drilling, extruding, punching, curling and indenting.

Design automation for custom sheet metal products

We use DriveWorks to automate custom product design, enabling faster production of products such as bespoke sheet metal doors, panels, shelves, windows, box design, etc.

Weldment design for sheet metal parts

We develop optimized weldments designs for your fabricated sheet metal components, which will be designed to maximize structural integrity and ease of fabrication.

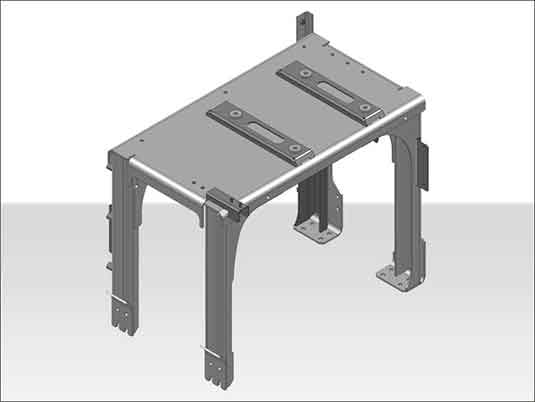

3D sheet metal modeling with DFM

We develop 3D models of your custom fabricated sheet metal component considering sheet metal bend radius, edges, flanges, etc. with Design for Manufacturing (DFM) best practices.

Flat pattern drafting for CNC & cutting

Complete construction document set, with dimensions, cutting design, section views, exterior elevations, as-built drawings and shop drawings.

CAD conversion from legacy files

We convert your legacy design data from image files, PDF’s, etc. to CAD format for use with modern manufacturing workflow.

DFM-compliant sheet metal part design

We design sheet metal parts with stamping design and with accurate k-factor values for compliance manufacturability and to ensure accuracy, cost effectiveness and efficient usage of materials.

Sheet metal and design services for various products

- Doors, windows & frames

- Sash, moldings & trims

- Grills & louvers

- Shelters structures & canopies

- Awnings

- Signage

- Balustrades

- Walkways & ramps

- Stair railings & treads

- Steel stairs & stair lifts

- Storage tanks

Why should you partner with our sheet metal drafting experts

Industries we serve for sheet metal drafting

- Commercial facilities and stores

- Educational buildings

- Financial institutions

- Restaurants and hotels

- Government installations

- Retail stores

- Hospitals and laboratories

- Warehouses and industrial units

FAQ’s about sheet metal design services

The importance of designing sheet metal lies in creating the exact blueprint for fabrication, reducing potential fabrication error and optimizing material use and therefore cost.

Sheet metal design services provide accurate CAD drawings with all of the necessary information (bend allowance, tolerance, etc.) so that the fabricator has no opportunity for misinterpretation.

Deliverables include detailed CAD drawings (for each part), flat patterns, Bill of Materials (BOM) for parts and quantities needed for manufacturing, manufacturing specifications and DXF/DWG files compatible with CNC equipment.

By designing sheet metal accurately, designers can consider material properties, limit bending and other fabrication limits, and tolerances at the time of initial design. This reduces fabrication errors and the amount of scrap generated.

Yes, legacy designs are converted or updated to the latest standards so they may be used on current fabrication equipment and processes.

Our Customers

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.