info@truecadd.com

Enhance Project Efficiency and Accuracy with Precise Structural Steel Modeling Services

Inaccurate dimensions, outdated data, frequent site changes, and safety risks can derail projects. If you are a structural engineer, fabricator, or contractor using old drawings or outdated methods for structural steel design it can create greater rework and costs. We can help you overcome these problems through comprehensive, customized structural 3D modeling services.

Our structural steel modeling services provide a host of benefits that includes removal of guesswork, interference detection, accurate material use, weld details, and lower site modifications. Our 3D modeling services include steel framing, 3D steel, footing and steel column, and As-Built modeling. Our coordinated and interference-free models are fully compliant as per international standards including AISC, ANSI, OSHA, and RSIO.

TrueCADD leverages enterprise grade BIM infrastructure for automated clash detection, interdisciplinary coordination, and structural analysis integration. Our team of 200+ Revit certified experts have over 30+ years of experience and ensure you get optimized documentation workflows, QA QC processes and BIM collaboration. We have successfully completed over 1,000 projects and offered high quality Revit structural steel modeling services, accelerated project delivery and reduced coordination overhead to clients across 50+ countries.

Our Revit Structural Steel Modeling Services

-

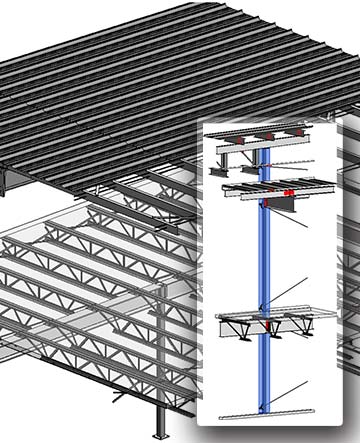

Structural Steel Framing Modeling

Create precise 3D models for frames and beams to ensure higher structural support.

-

Structural 3D Steel Modeling

Build comprehensive 3D steel models that prevent errors and expedite construction.

-

Miscellaneous Metal Work Modeling

Develop 3D models for ladders, rails, and stairs with accuracy for secure installation.

-

2D Drafting and 3D Modeling

Provide 3D models and 2D drawings to achieve accurate manufacturing and steel erection.

-

Footing and Steel Columns Modeling

Build footing and column models with accurate details to build a robust foundation.

-

Structure As-built Modeling

Document the final conditions with precise 3D models that can be used for future reference.

Benefits of Structural Steel Modeling

Significant Accuracy

Structural steel modeling prevents design issues by identifying interferences and issues before manufacturing.

Material Use

Extracting precise material quantities for steel directly from the structural 3D model reduces material waste.

Quick Fabrication

Clear, data rich and comprehensive shop drawings from the 3D model expedites manufacturing of steel members.

Effective Installation

Detailed 3D modeling ensures every building part fits perfectly on the site while eliminating changes and delays.

Profound Coordination

3D models uploaded on platforms such as BIM 360 ensures every team member has access to the latest files.

Cost Reduction

Faster problem detection reduces rework, lowers material waste, and eliminates delays to abate overall costs.

Advantages of Outsourcing Structural Steel Modeling Services

- Significant reduction in overhead and labor expenses in comparison to in-house teams.

- Large talent pool can help you with precise steel models driven by industry standards.

- Quick handovers with dedicated teams can meet condensed timelines without delays.

- Faster ramp up or down capability based on project complexity and scale.

- Complete access to advanced tools and platforms without additional costs.

- Engineers and contractors can focus on construction while experts handle the modeling job.

Sectors We Cater To

Residential Buildings

Commercial & office buildings

Healthcare

Airports

Schools & Universities

FAQ’s related to structural steel modeling services

Structural steel modeling is the process that includes the development of 3D models and 2D drawings of steel structures for fabrication and erection.

Structural 3D modeling provides enhanced visualization of every steel element with detail to prevent errors and ensures a precise fit with other building components.

Yes, outsourcing structural steel modeling to a reliable partner like TrueCADD will save costs on rework, reduce waste, and accelerate manufacturing resulting in reduction of overall costs.

We clash test every model after it is coordinated to remove conflicts between various trades including architecture, structure, and MEPF.

Structural steel modeling services can be leveraged by people and firms including contractors, engineers, builders, and fabricators to realize greater project precision.

Definitely, structural steel modeling services will help you with a large skilled talent pool, quick turnaround, and complete access to advanced tools at reduced costs.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.