Leading CAD Outsourcing Company offers solutions of Engineering CAD Services, Design Drafting & 3D Modeling

Email us:

info@truecadd.com

info@truecadd.com

Leading CAD Outsourcing Company offers solutions of Engineering CAD Services, Design Drafting & 3D Modeling

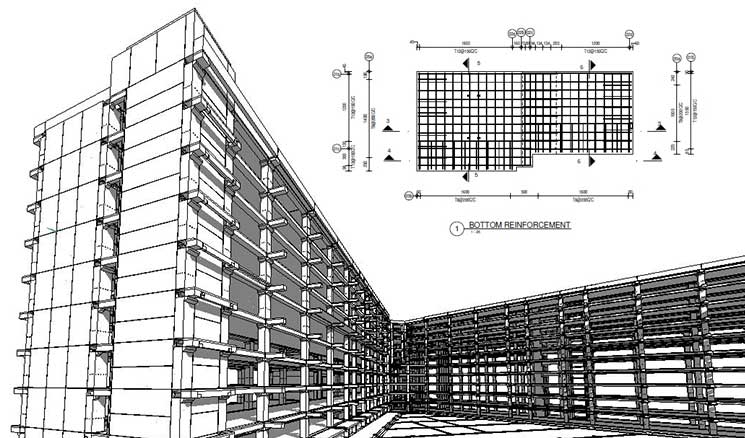

Clash-free 3D Precast Model at LOD 450 for a Residential Project, UAE

Client Profile:Precast Manufacturer

Industry:Pre-cast Manufacturing

Inputs:AutoCAD drawings, Excel and PDF files

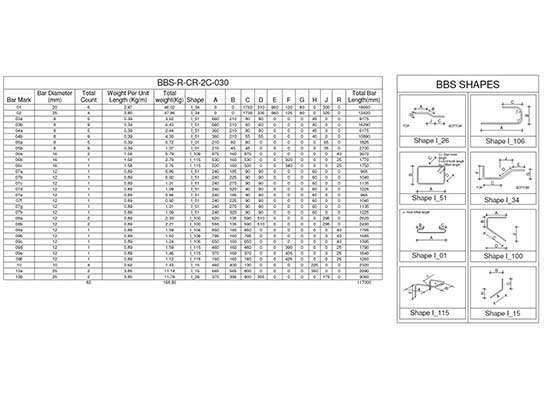

Deliverables:3D Model at LOD 450, Rebar Shop Drawings of concrete elements, BBS

Software Used:

Let’s Talk.

Optimize your precast workflows with clash-free LOD 450 modeling and precise Rebar detailing.

Connect with our BIM specialists →Business Needs:

- Develop a 3D BIM model at LOD 450 with < 5mm clash-free precast elements.

- Generate accurate Rebar Shop Drawings with BBS and 3D views.

- Assign unique element IDs for tracking and sequencing.

- Provide quantity reports, material lists, and visual aids for precise installation.

Project Challenges:

- Convert 2D design drawings into clash-free 3D BIM models.

- Ensure compliance with local regulations through continuous technical training.

- Manage evolving precast designs with coordination across adjacent elements and structures.

- Scale resources efficiently to meet dynamic project needs.

Our Solutions and Approach:

A UAE precast manufacturer approached TrueCADD to create a clash-free and coordinated 3d BIM model with 5mm for a residential project.

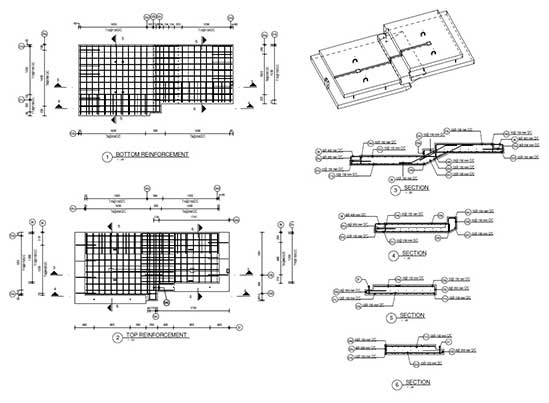

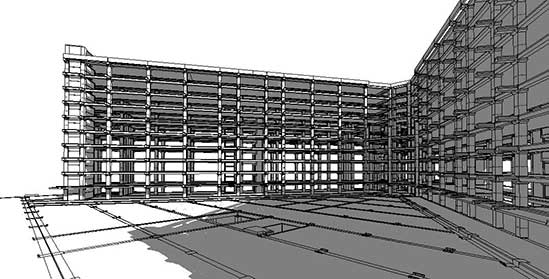

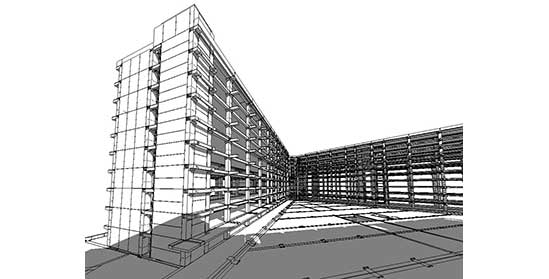

- Developed clash-free 3D BIM model at LOD 450 using Revit and BIM 360.

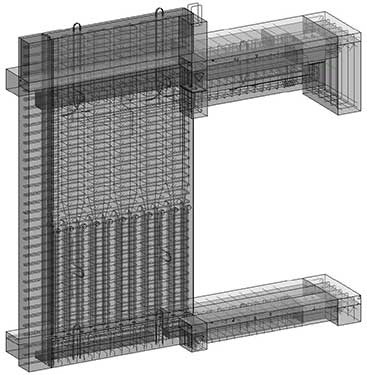

- Created Rebar Shop Drawings and BBS with precise lengths, shapes, bends, and 3D views.

- Standardized RFIs to minimize scheduling errors.

- Produced accurate BOQs, BOMs, and schedule estimates for faster procurement.

- Used Object-Based Modeling for early design changes and optimization.

- Performed clash coordination to improve timelines and reduce costs.

- Conducted quality checks on precast elements and overall project.

- Implemented workflows for fast issue resolution and accurate material estimation using unique element IDs.

Business Impact:

- Delivered < 5mm clash-free 3D models for M60 concrete grade.

- Completed BIM models and shop drawings in 6–8 months.

- Improved Rebar and precast production quality.

- Enabled fast, accurate construction with unique IDs.

- Reduced concrete casting costs with mould drawings.

Project Samples

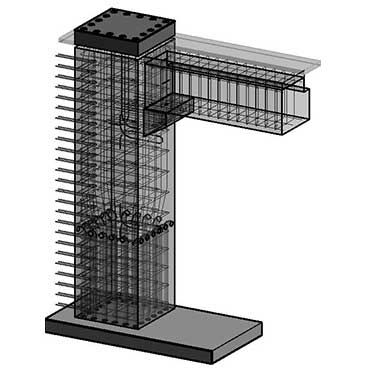

Staircase Reinforment

Detail Bar Bending Schedule

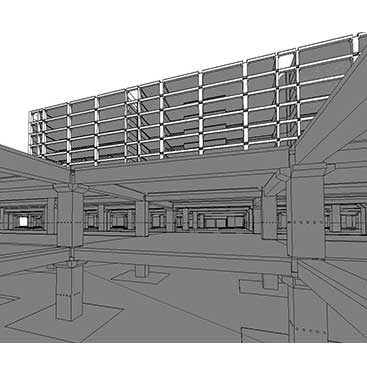

Building Perspective View

Building Image

Column Beam Slab Junction

Column Beam Junction

Building Internal View

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.