Leading CAD Outsourcing Company offers solutions of Engineering CAD Services, Design Drafting & 3D Modeling

Email us:

info@truecadd.com

info@truecadd.com

Leading CAD Outsourcing Company offers solutions of Engineering CAD Services, Design Drafting & 3D Modeling

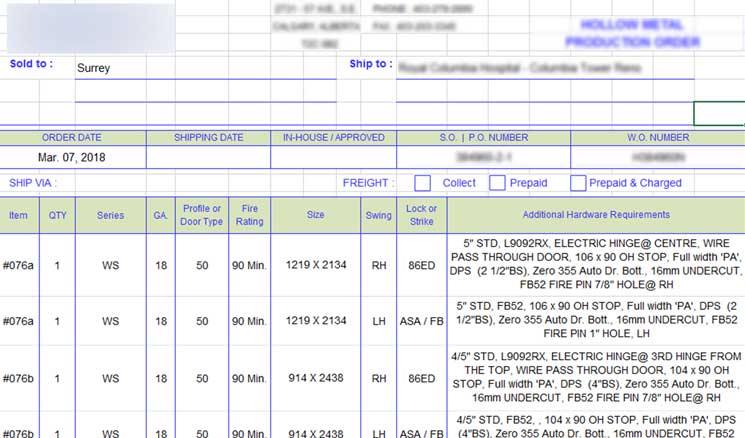

Material Estimates Enabled Manufacturers of Door and Frames to Estimate Costs Accurately

Client Profile:Hollow metal and wooden doors, frames, windows, and hardware manufacturer

Industry:Building products manufacturing

Inputs:Architectural 2D drawings and door-window schedules

Deliverables:Excel files with detailed material estimates

Software Used:

Let’s Talk.

Streamline project bids and pre-bid feasibility with detailed quantity takeoffs.

Connect with our experts today →Business Needs:

- Implement accurate cost calculation methods to manage rising bid volumes.

- Replace error-prone legacy estimating processes.

- Speed up door and window project bidding cycles.

- Use automated cost modeling to improve pricing accuracy.

Project Challenges:

- Manage multiple estimation templates for varying door and window specifications and quantity takeoffs.

- Select the correct door hardware based on door type, frame configuration, and size constraints.

- Verify fire-rating compliance for doors, windows, and associated hardware.

- Consolidate scattered project data to support manufacturing, procurement, installation, and delivery planning.

Our Solutions and Approach:

A Canadian door and frame manufacturer approached TrueCADD to obtain accurate quantity takeoffs and submit bids with confidence.

- Analyzed architectural drawings to extract precise quantity takeoffs for doors, frames, windows, sidelites, transoms, open cases, and hardware using Comsense for specialty doors.

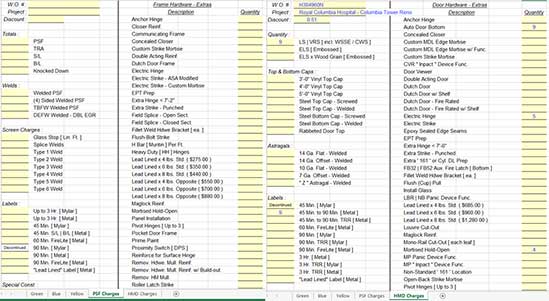

- Built unit-based estimation matrices to calculate hollow metal door charges, PSF frame costs, and door-frame quantities accurately.

- Reviewed and version-controlled drawings using PlanGrid while selecting room-wise doors, frames, and windows through coordinated markups.

- Trained the estimation team under the client’s chief estimator to follow project-specific costing logic using template-driven Microsoft Excel workflows.

- Validated final material takeoffs through random quality checks to deliver error-free, bid-ready estimation sheets.

Business Impact:

- Accelerated feasibility checks and quote finalization.

- Reduced estimation time for complex door and window assemblies.

- Increased quote volume and customer response capacity.

- Ensured consistent pricing accuracy and reliability.

Project Samples

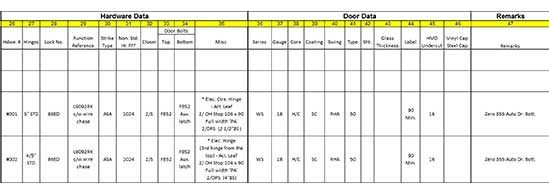

Metal Doors and Frame Hardware Details

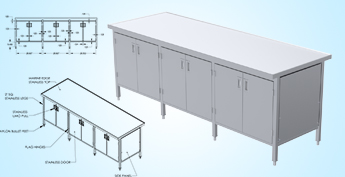

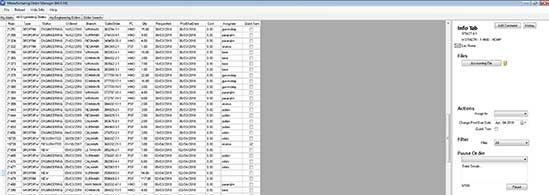

Manufacturing Order Manager MOM

Configurator Sheet for Hardware and Door Data

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.