Leading CAD Outsourcing Company offers solutions of Engineering CAD Services, Design Drafting & 3D Modeling

Email us:

info@truecadd.com

info@truecadd.com

Leading CAD Outsourcing Company offers solutions of Engineering CAD Services, Design Drafting & 3D Modeling

Adopted Top-down Approach to Developed 3D Model & 2D Drawings for Walkway and Hoppers

Client Profile:A 45-year-old engineering and recycling company providing proven, customized solutions that divert waste and give clients peace of mind.

Industry:Engineering recycling solutions

Inputs:STEP files of solid models for walkways and plant assembly for hoppers

Deliverables:Output 3D model and 2D drawings for walkway and hoppers

Software Used:

Let’s Talk.

Deliver error-free hopper and walkway drawings on time with our parametric CAD expertise.

Partner with us Now →Business Needs:

- Need additional CAD drafting team to meet deadline targets.

- Require drafters skilled in Creo for sheet metal design and detailing.

- Perform conveyor collision checks to identify layout issues.

- Verification of waste flow slope and available plant layout space required.

Project Challenges:

- Redesign of hopper models due to conveyor position adjustments.

- Need for a solution to reduce errors in hopper-conveyor interface modeling.

- Difficulty managing large assembly files leading to slow loading times.

- File load times of 30–45 minutes causing productivity delays.

Our Solutions and Approach:

An Ireland-based recycling plant manufacturer and installer partnered with TrueCADD to reduce manufacturing rework and save design time using a top-down design approach.

- Followed top-down methodology to minimize design errors and reduce design duration.

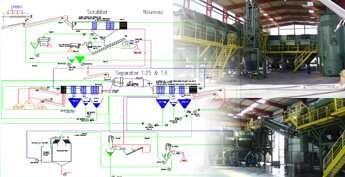

- Analyzed STEP files containing plant and assembly data to identify layout and interface restrictions.

- Enabled flexible parametric design for adjusting conveyor placement positions.

- Facilitated rapid coordination calls to raise RFIs and resolve technical queries.

- Created Creo-based parametric 3D models for walkways, hoppers, handrails, and guardrails.

- Developed 2D manufacturing and installation drawings adhering to established standards.

- Conducted senior-engineer quality assessments, including sheet thickness verification, clearance measurement, and clash detection evaluation.

- Distributed approved models and drawings through a controlled file transfer to ensure timely delivery.

Business Impact:

- Boosted manufacturing output with 55 hoppers delivered monthly.

- Enabled high-volume CAD output for scalable operations.

- Achieved 99.9% accuracy to reduce production errors.

- Improved design delivery speed and reliability.

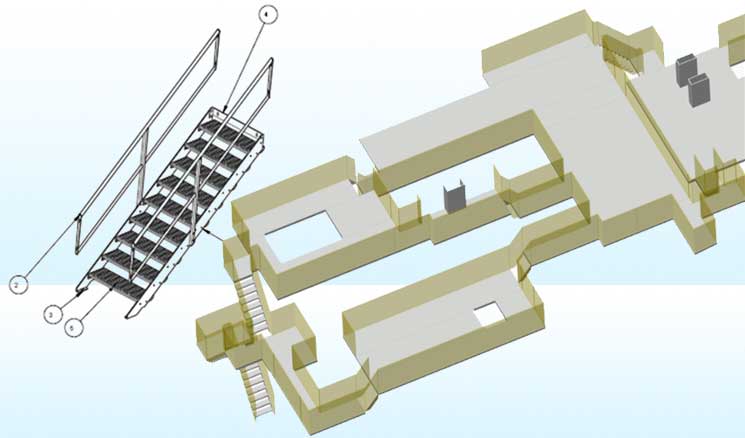

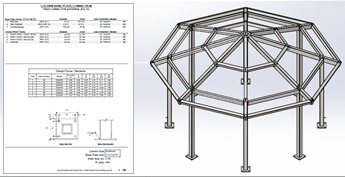

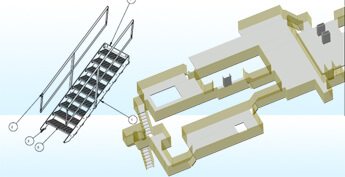

Project Samples

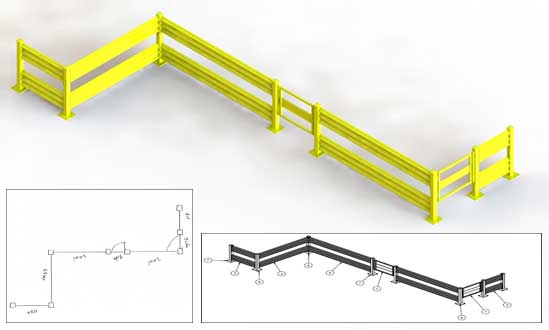

Gaurdrail 2D Drawings and 3D Model

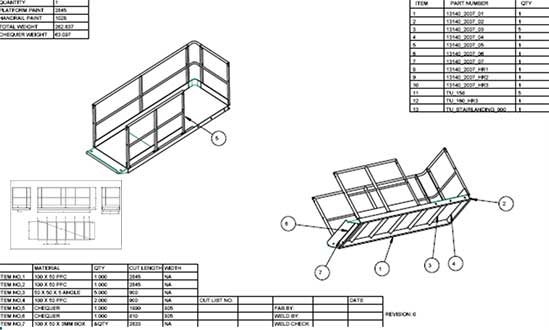

Handrail CAD Drawings

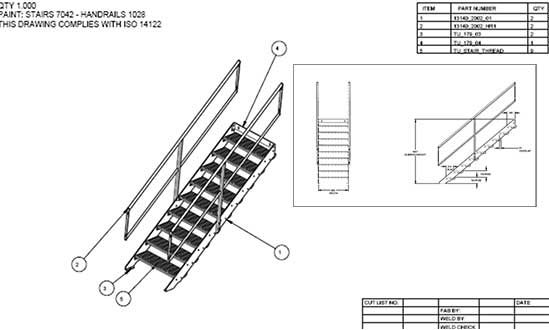

Staircase 2D Manufacturing Drawings

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.