Leading CAD Outsourcing Company offers solutions of Engineering CAD Services, Design Drafting & 3D Modeling

Email us:

info@truecadd.com

info@truecadd.com

Leading CAD Outsourcing Company offers solutions of Engineering CAD Services, Design Drafting & 3D Modeling

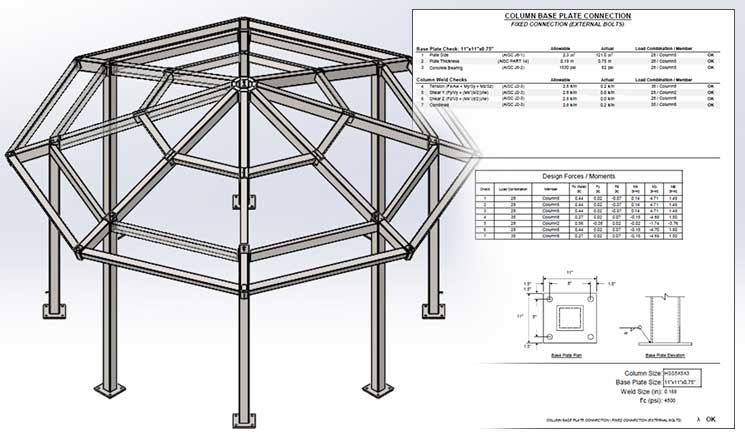

Reduced design iterations by 50% by delivering expert SolidWorks design and drafting support for over 1,800 shelter drawings.

Client Profile:Shelter Manufacturer

Industry:Open-Air Steel Structure Manufacturing

Inputs:Complete SolidWorks 3D model packages hosted on the client’s MES server.

Deliverables:SolidWorks 3D models – parts and assemblies and 2D manufacturing and assembly drawings with complete Bills of Materials (BOMs)

Software Used:

Let’s Talk.

Transform your shelter designs into fabrication-ready drawings with our expert CAD support.

Connect with us →Business Needs:

- Deploy experienced CAD engineers to manage heavy design workloads and tight delivery timelines.

- Reduce drafting cycle time through error-free and standardized CAD workflows.

- Ensure accurate detailing of parts, hole patterns, and hardware components.

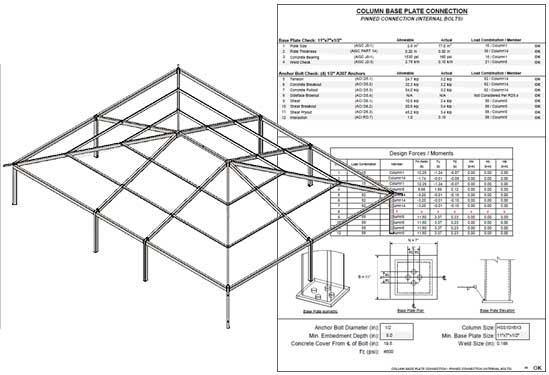

- Maintain structural integrity while complying with applicable US regulatory standards.

Project Challenges:

- Incomplete and inconsistent input data complicated SolidWorks part and assembly modeling.

- Under-constrained sketches caused geometric instability and constraint conflicts.

- Component misalignments occurred in large and complex shelter assemblies.

- Strict dimensional and geometric accuracy was required to meet manufacturing tolerances.

Our Solutions and Approach:

A steel shelter manufacturer from the USA engaged TrueCADD to provide end-to-end SolidWorks 3D modeling and drafting support across multiple shelter structures.

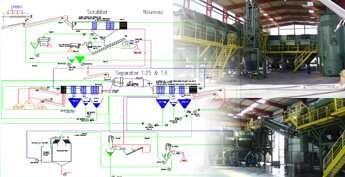

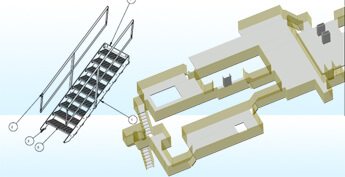

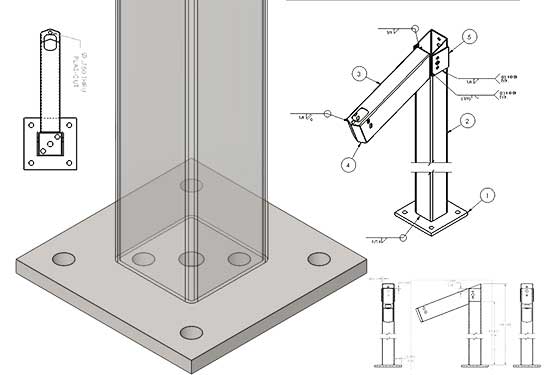

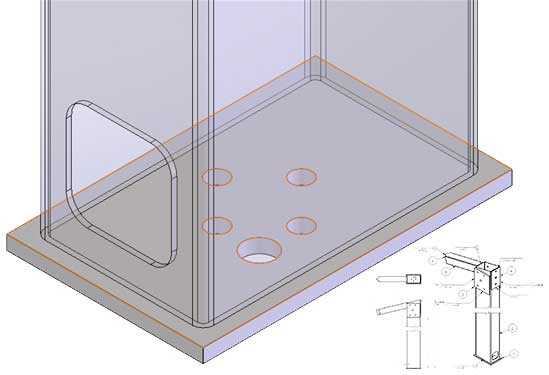

- Developed complete 3D part and assembly models for steel shelter structures from concept to fabrication.

- Accessed and processed client SolidWorks files directly from the MES server for seamless collaboration.

- Resolved hole placements, hardware detailing, plate alignment issues, and interferences within 3D assemblies.

- Raised and tracked multiple RFIs to address design gaps and incomplete data.

- Implemented standardized drafting procedures to improve coordination and drawing consistency.

- Applied top-down modeling techniques to efficiently manage large structural assemblies.

- Produced 2D manufacturing and assembly drawings compliant with US industry standards.

- Delivered over 1,800 drawings with peer reviews and multi-level quality checks prior to secure MES upload.

Business Impact:

- Accelerated overall project completion by 25% using top-down modeling workflows.

- Reduced design iterations by 50% through accurate offshore CAD execution.

- Minimized material waste and rework with high-precision detailing.

- Achieved 99.8% product quality through rigorous quality control and validation processes.

Project Samples

Production Drawings for Shelter Assembly

CAD Drafting for Shelter Manufacturing

3D Modeling for Shelter Parts

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.