Leading CAD Outsourcing Company offers solutions of Engineering CAD Services, Design Drafting & 3D Modeling

Email us:

info@truecadd.com

info@truecadd.com

Leading CAD Outsourcing Company offers solutions of Engineering CAD Services, Design Drafting & 3D Modeling

Reduced delivery time by 30% and cost by 18% by converting Revit BIM data into manufacturing-ready Autodesk Inventor CAD models.

Client Profile:Manufacturer of Industrial Equipment

Industry:Construction

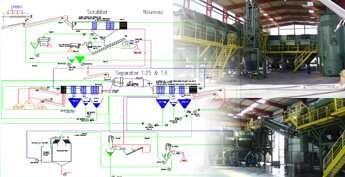

Inputs:Revit BIM layout for the seating and spectator areas of a 60,000-seat football stadium

Deliverables:2D manufacturing and installation shop drawings and 3D CAD models developed in Autodesk Inventor

Software Used:

Let’s Talk.

Transform your BIM data into manufacturing-ready drawings

Contact our experts →Business Needs:

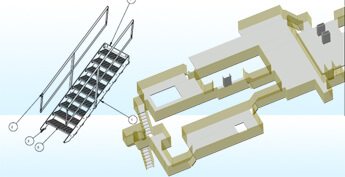

- Develop detailed 3D CAD models and fabrication-ready shop drawings for handrails and balustrades across a 60,000-seat football stadium.

- Convert Revit BIM data into precise Autodesk Inventor CAD files suitable for manufacturing.

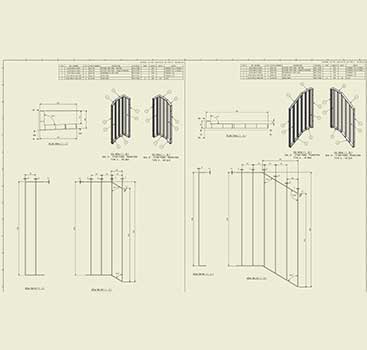

- Produce 2D manufacturing and installation drawings compliant with Australian Standards.

- Ensure fabrication-ready outputs to support efficient on-site installation.

Project Challenges:

- Ensuring lossless Revit-to-Inventor data conversion without geometry degradation.

- Managing .SAT file conversions that caused multi-assembly solid merging issues.

- Meeting aggressive turnaround timelines for 2D and 3D CAD deliverables.

- Delivering daily production-ready outputs to support next-day fabrication.

- Coordinating inputs from multiple client points of contact (POCs) while maintaining drawing consistency.

Our Solutions and Approach:

An industrial equipment manufacturer from Australia approached TrueCADD to develop 2D manufacturing shop drawings and 3D Inventor models for a large-scale stadium project. Key challenges included:

- Successfully converted complex Revit BIM models into Autodesk Inventor CAD models, reducing delivery time by 30%.

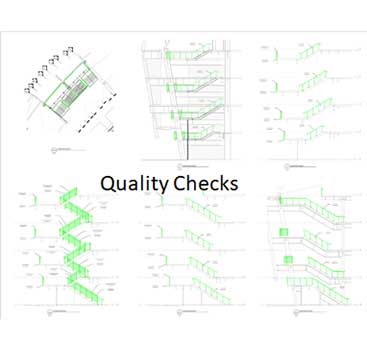

- Established standardized 2D drafting and 3D modeling guidelines to ensure execution consistency.

- Implemented a unified Revit-to-Inventor workflow for seamless design-to-manufacturing transition.

- Developed a reusable standard CAD component library to accelerate modeling and detailing.

- Incorporated continuous client feedback to ensure all drawings met project specifications and Australian Standards.

- Scaled the project team and conducted internal training to maintain productivity under tight schedules.

- Delivered coordinated 3D models with detailed 2D manufacturing drawings to minimize material waste and rework.

Business Impact:

- Achieved 100% accurate Revit-to-Inventor BIM conversion.

- Accelerated CAD model and shop drawing delivery by 30%.

- Reduced overall project costs by 18% through streamlined drafting and optimized workflows.

Project Samples

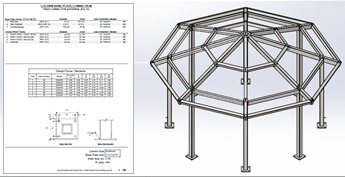

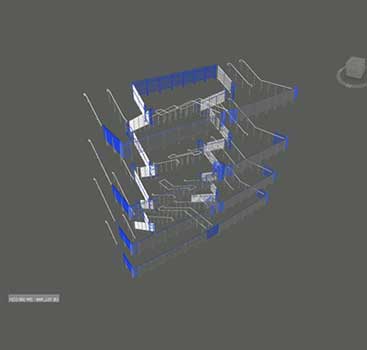

Revit BIM Models for Football Stadium

Quality Assurance for Manufacturing Drawings

Quality checklist and query Report

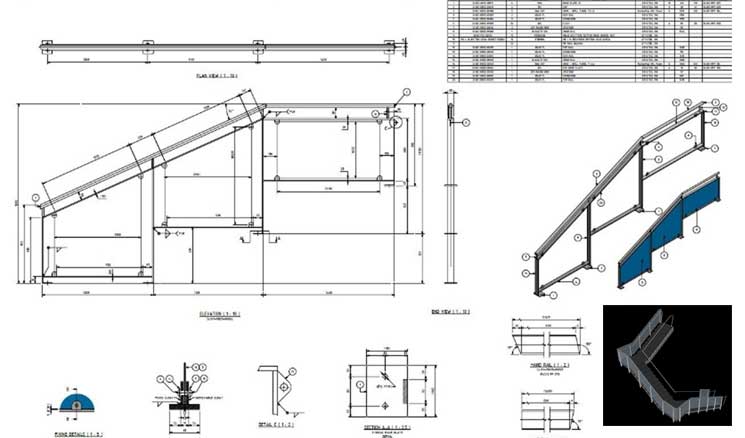

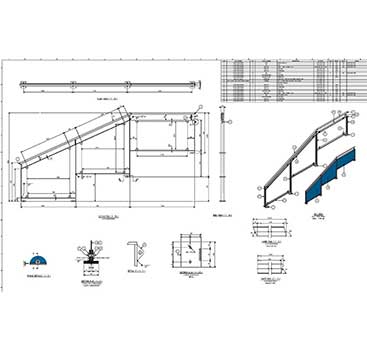

Manufacturing CAD Drawings for Balustrades

Handrails Manufacturing Drawings

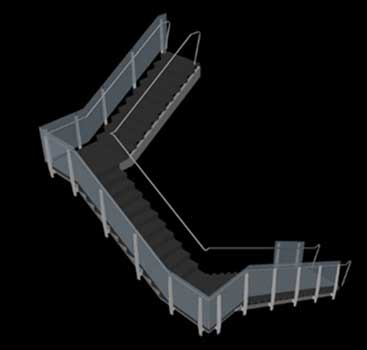

3D CAD Model of Stairs

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.