Today’s BIM technology comes with augmented BIM models with the additional dimensions of calculating material and cost estimates. 4D BIM scheduling and 5D BIM modeling enables better-planning and more cost-effective construction.

info@truecadd.com

Benefits of 4D & 5D BIM to Construction Projects

In today’s digitalized world 4D BIM and 5D BIM are leading the BIM technology wave and are set to revolutionize the construction industry. By integrating information rich 3D BIM models with additional dimensions of scheduling and cost and material estimations, 4D and 5D BIM modules manage better the effect of change in orders on project costs and scheduling.

This promises to reverse the construction industry’s annual losses pegged at $177B due to poor communication, rework, and bad data management.

Importance of 4D and 5D BIM in the AEC industry

From 2D to 3D BIM modeling, BIM technology has come a long way. 4D BIM adds the dimension of time to 3D models, by incorporating scheduling data, thereby allowing stakeholders to visualize project progression over time.

Visualizing the construction process from start to finish, considering the sequence of activities and the timeline for each task leads to efficient project planning, resource allocation, and identifying potential delays. AEC stakeholders can also identify potential clashes or bottlenecks, and make informed decisions to optimize the construction process.

On the other hand, 5D BIM combines 3D geometry with cost data, enabling real-time cost tracking, accurate estimation, and better budget management. This advanced insight into both scheduling and cost aspects enhances decision-making, minimizes risks, and improves overall project efficiency, making 4D and 5D BIM invaluable tools for optimizing construction processes and outcomes.

What are the common challenges for cost and schedule overruns?

The most common issues are:

- Inaccurate project planning during the initial construction stages.

- Inaccurate project estimates during initial stages due to absence of sufficient data.

- No planning or readiness for change orders.

- Administration errors caused due to system flaws or human errors.

- Poor operational work flow and un- streamlined processes.

Read here: Types of 4D BIM Construction Scheduling Techniques

Benefits of 4D BIM to construction projects

Builders and contractors have several construction sequencing options to choose from, including the simple and conventional 4D scheduling techniques, which can help them, keep construction projects on schedule. It provides several prominent alternatives for addressing the project requirements and to overcome any challenges. With various capabilities including, a 4D BIM model and 4D construction simulation supports furthermore the accurate information collection process.

In more detail, 4D in construction can do the following for your organization:

Clash-free 4D BIM Scheduling

It generates information about the schedules of building products and creates a visual in a step-by-step method. For different building components, 4D BIM scheduling incorporates time related information like lead-time, construction and installation time, allowances for drying and mixing period, and inter dependency on other products.

4D Graphical Visualization

The scheduling data is utilized within Navisworks 4D simulation and is easily convertible into graphical design, which helps in comparing the scheduled plan with the actual plan.

Optimal Resource Utilization

Properly planned data in the form of graphs and datasheets lends greater visibility and aids resource mobility and better resource planning. The coordinated approach also helps in optimal resource utilization, achieving higher operational efficiencies and in meeting timelines.

Better Interdisciplinary Coordination

Since rework is minimized and each worker on site is adequately informed about what he would be working upon at a particular phase of construction project, there is better coordination among various disciplines. The contractors can easily link this with activities of other disciplines and plan in a logical manner by maximizing the work efficiency of each worker on construction site.

Top 10 best practices for accurate 4D BIM scheduling in construction

4D BIM scheduling in construction involves reinforcing time-related information into the 3D BIM model, allowing for better visualization and planning. Provided below are best practices to achieve accurate and effective 4D BIM scheduling with a 4D BIM model.

- Preconstruction collaboration: Implement 4D BIM scheduling in the preconstruction stage. Involve every stakeholder, including designers, contractors, and subcontractors, to achieve effective and efficient project collaboration.

- Accurate Data Sets: Ensure that all data used in the 4D BIM model is accurate and updated. Discrepancies or inaccuracies in the input data can lead to errors in scheduling.

- Clear Task Dependencies: Generate task dependencies between various tasks in the schedule. Understand critical task dependencies to avoid delays and conflicts with 4D in construction.

- Realistic Schedules: Avoid guessing in creating schedules and assign realistic schedules to each task based on historical data, industry standards, and expert input.

- Resource Allocation: Allocate resources appropriately by considering the labor availability, equipment, and materials to avoid over utilizing or underutilizing resources.

- Plan Contingencies: Incorporate contingency time in the schedule to manage and resolve unexpected events without causing major issues.

- Regular Updates: Update 4D BIM scheduling as the project progresses through various stages. This helps identify and resolve any deviations from the planned timeline and make necessary schedule adjustments.

- Collaboration and Communication: Communicate and collaborate with multiple project participants to discuss schedule updates and resolve potential issues. Utilize the 4D BIM model to achieve visual scheduling for all stakeholders. This makes it easier for key stakeholders to understand project progress.

- Manage Risks: Identify and resolve potential risks with proactive risk management to minimize project disruptions.

- Skill Development: Ensure every team members involved in 4D BIM scheduling has the necessary skills to achieve accurate schedules and adopt Navisworks 4D simulation.

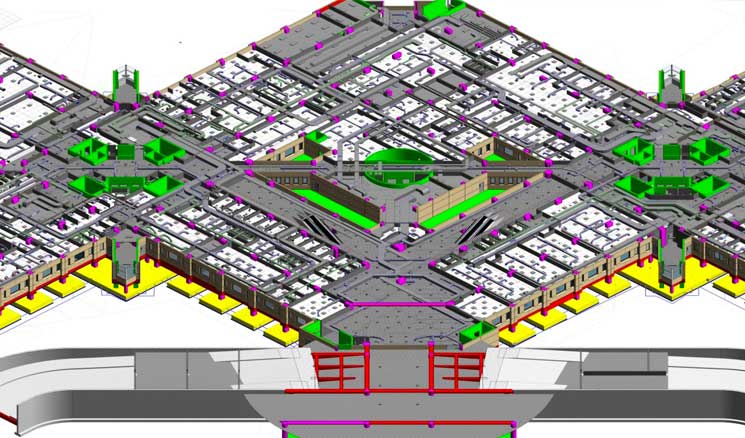

4D BIM scheduling for a mixed-use project in the UK reduces rework and saves costs

An architectural firm from the UK outsourced its project to us to create a 4D BIM coordinated model with sequencing and a project introduction in video form. Our team utilized Revit, 3DsMax, and Navisworks for this mixed-use building project and built a coordinated 4D BIM model with construction scheduling within a timeframe of 2 months. The deliverables helped the client improve design intent, save costs, and reduce rework by a significant amount.

Architectural BIM Model

Architectural BIM Model

Structural BIM Model

Structural BIM Model

MEP BIM Model

MEP BIM Model

Benefits of 5D BIM to construction projects

5D BIM, is the next step up from 4D (time scheduling), but furthermore integrates design with estimates such as for and cost, and includes the generation of quantities (BOMs/BOQs), development of rates and overall cost.

Enhanced Cost Forecast and Estimation

The exact quantity of various building components generated by higher level of detailing with manufacturer details from the 3D models can be compared with the current purchasing rates with 5D modeling to estimate the cost for entire structure.

More Accurate and Faster Quantity Take offs

On an average, estimators spend 50% to 80% of their time in creating a creating a quantity take off for cost estimating. 5D BIM in construction reduces human errors, saves cost and time. With more time on their hands, estimators can focus on other important project specific factors like assessing financial risk factors and identifying construction assemblies involved, generating pricing etc.

Over 60% of construction failures are due to economic factors, mostly because of lack of liquidity on daily activities. This problem is simply solved by linking cost information to the traditional 3D model and scheduling, also known as 5D BIM. This dimension allows the instant creation of financial estimations against time, greatly reducing the time consuming task of quantifying resources and estimating costs from days to minutes while also minimizing errors.

Automated Quantity take offs as per Design Modifications

Whenever a single component is modified, the direct impact on the cost is calculated automatically. By using 5D BIM cost estimation instead of drawings, the take-offs, counts and measurements are generated directly from the underlying model. Therefore, the information is always consistent with the design. When any change is made in the design, the change automatically ripples to all related construction documentation and schedules, take-offs, counts and measurements that are used by the estimator.

Easy Selection of available Options

Accurate and quick BIM cost estimation while analyzing various design options within a fraction of time makes it easier for the architect to choose design option as per the client’s requirements. This also helps owners, contractor and sub-contractors during bidding phase.

Multi-Platform Access

Addition of cloud technology to BIM allows access of data from anywhere and on any device to contractors and project managers. You don’t need to be physically present on the construction site. This helps you coordinate better with your teams on schedules or change in design or plans.

Top 5 best practices for accurate 5D BIM cost estimation in construction

5D BIM modeling is an advanced approach to construction that reinforces the 3D BIM model with cost estimates. It fuels accurate and detailed cost analysis throughout the construction project lifecycle. Provided below are five best practices to achieve accurate and effective 5D BIM in construction:

- Preconstruction Collaboration and Data Integration: Facilitate collaboration among all project stakeholders in the preconstruction stage, including architects, engineers, contractors, and cost estimators. By integrating cost estimation information into the 3D BIM model early on, potential cost implications can be identified, material choices can be improved and informed decision-making can be achieved.

- Accurate and Updated Data: Ensure data within the 5D BIM model is accurate, up-to-date, and validated. This includes material costs, labor rates, equipment expenses, and other relevant cost-related information.

- Define Cost Breakdown Structure (CBS): Create an accurate and comprehensive Cost Breakdown Structure that factors all construction costs, for quick expense tracking and management. Align the CBS with the project’s Work Breakdown Structure (WBS) to facilitate quick integration with the 3D BIM model for achieving cost estimation at various levels of detail (LOD).

- Deploy Parametric Cost Modeling: Incorporate parametric cost modeling for 5D BIM cost estimation. Parametric cost models utilize predefined cost data based on key project parameters and characteristics leading to quick and validated cost estimates.

- Perform Regular Cost Reviews: Review and analyze the cost data within the 5D BIM model throughout various stages of the project lifecycle. Monitor the actual costs against the estimated costs to identify potential cost overruns. Regular reviews support pattern and trend identification to make proactive decisions on project budget.

Implementing these best practices, draws in more accurate cost estimates, better cost control, and improved decision-making, leading to successful project outcomes.

BIM model at LOD 500 saves construction time for a UK-based healthcare project

A project management solutions client from Saudi Arabia approached our team for a healthcare construction project. MEP BIM modeling services were required from our end to create a coordinated 3D model using 2D drawings. Our team utilized tools like Revit and Navisworks to create a 3D BIM model at LOD 500 and resolve clashes. The interference-free model helped the client lower rework, streamline construction, and save construction time.

LOD 500 Modeling in Revit

LOD 500 Modeling in Revit

The Future of 4D and 5D BIM: AI and machine learning tools

In the rapidly evolving construction industry, AI and machine learning tools are becoming game-changers, making processes more efficient and accurate. Embracing these technologies for 4D BIM scheduling and 5D cost estimation has brought remarkable improvements. 4D BIM scheduling involves creating dynamic models that show the construction progress over time. AI algorithms help analyze historical data and resource availability to optimize schedules and anticipate potential issues. This proactive approach helps in reducing delays and cost overruns, benefiting both construction teams and clients.

5D cost estimation powered by AI helps crunch vast amounts of data from past projects while considering various factors like material costs, labor rates, and market trends. These tools deliver incredibly precise cost forecasts. They even adapt to real-time changes, like design modifications and supply chain fluctuations, keeping cost estimates up-to-date throughout the project.

The integration of AI and machine learning doesn’t just save time and resources but also enhances decision-making and project outcomes. Construction companies are witnessing increased productivity and better cost control. The future looks even brighter as these technologies continue to evolve, driving sustainable growth and innovation across the construction sector. Embracing AI is undoubtedly the way forward for construction businesses seeking success in this competitive landscape.

Conclusion

It is apparent that 4D and 5D BIM are revolutionizing the construction industry. The integration of information rich 3D BIM models with added dimensions of scheduling (4D) and cost/material estimation (5D) ensure better management of change orders on project costs and scheduling. Integration of the cloud technology with BIM, allows stakeholders to access data from anywhere on any device.

Governments in most countries across the world have mandated BIM adoption for professionals in the AEC sector. There are clear directives to implement new trends in BIM technology for efficient deployment of resources, planning, designing, managing and reducing rework during the construction process.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.