Microvellum enhances millwork drafting through parametric design, precise detailing, and production integration, improving accuracy and manufacturing support for millwork drafters while reducing errors and streamlining the production workflow.

info@truecadd.com

How Millwork Drafting in Microvellum Improves Accuracy and Manufacturing Support

Table of Contents

- What is millwork drafting and why it matters

- How Microvellum enhances millwork drafting accuracy

- Microvellum’s integration with manufacturing processes

- Key features that drive Microvellum’s performance for millwork manufacturers

- Reducing errors through Microvellum’s systematic approach

- Market segments benefiting from Microvellum drafting

- Conclusion

In millwork drafting, precision and efficiency are crucial factors for success. Millwork drafting in Microvellum offers industry-leading solution that addresses these fundamental requirements through its powerful integration with AutoCAD’s robust engine. This specialized platform offers detailed 3D drawing & modeling tools that help create production-ready output, effectively bridging the gap between design intent and fabrication.

Microvellum’s intelligent parametric objects, ease of creating documentation, and direct manufacturing integration provide substantial benefits for both small custom shops seeking precision and large manufacturing operations requiring consistency and speed across complex projects.

As millwork professionals face increasingly complex designs and tighter production schedules, Microvellum drafting capabilities deliver the accuracy and manufacturing support necessary to maintain quality while meeting demanding timelines.

What is millwork drafting and why it matters

Millwork drafting represents the essential process of creating technical drawings for custom woodwork elements including cabinetry, furniture, architectural details, and decorative components. These drawings serve as the critical communication bridge between designers, engineers, fabricators, and installers, ensuring that all stakeholders work from consistent, accurate information throughout the project lifecycle.

In millwork, even minor errors in measurements or specifications cascade into significant problems such as material waste, production delays, assembly difficulties, and installation challenges. High quality millwork drafting services helps solve these problems with accurately represented components and clear communication of design intent.

This ultimately helps enhance overall project profitability, making effective millwork drafting a critical competitive advantage in the industry. The specialized tools and methodologies within Using Microvellum for custom millwork projects helps address these requirements with accuracy and manufacturing support.

How Microvellum enhances millwork drafting accuracy

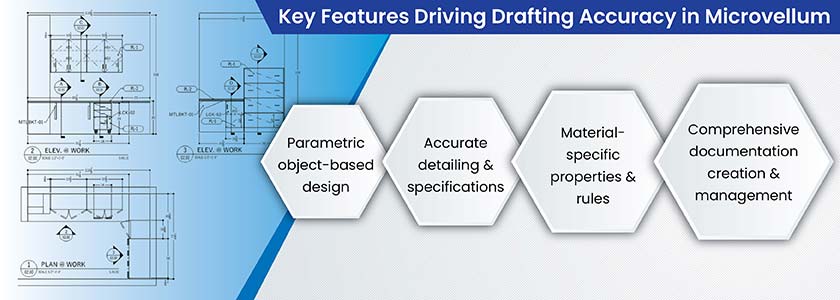

The precision achieved through Microvellum drafting process stems from several key technological advantages embedded within the software’s architecture. These capabilities work together to create an integrated drafting environment specifically optimized for millwork applications.

Parametric object-based design

Microvellum utilizes parametric modeling where components exist as intelligent objects with built in rules and relationships. This approach ensures that when one element changes, all connected elements automatically adjust accordingly, maintaining dimensional accuracy and proper relationships throughout the entire design.

For example, when modifying cabinet dimensions, the system automatically updates internal shelving, drawer configurations, hardware placements, and material requirements. This parametric intelligence eliminates the common drafting errors that occur when changes to one component are not accurately reflected in related elements.

This object-based approach also enforces manufacturing rules, preventing designers from creating impossible configurations that would cause problems in production. Each parametric object contains embedded knowledge about manufacturing constraints, material properties, and assembly requirements.

Accurate detailing and specifications

Microvellum shop drawings achieve exceptional detail because the software helps easily manage much of the specification process. Rather than manually drafting each component, the system generates precise construction details based on predefined standards and manufacturing requirements.

The detailing capabilities streamline the creation of critical information including:

- Dimensioning that reflects actual manufacturing requirements

- Joint details that accurately represent construction methods

- Hardware placement that accounts for clearance and structural needs

- Finish specifications that properly identify material treatments

This elimination of repetitive manual drafting reduces the potential for human error while ensuring that specifications remain consistent across all project documentation.

Material-specific properties and rules

One of the major Microvellum accuracy benefits comes from its incorporation of material-specific properties and manufacturing constraints directly into the drafting process. The software understands the real-world limitations of different materials and manufacturing methods, automatically applying appropriate rules during the design process.

These material-specific considerations include:

- Actual material thicknesses rather than nominal dimensions

- Grain direction requirements for aesthetic and structural integrity

- Hardware specifications with proper clearances and mounting details

- Tooling capabilities and limitations for CNC manufacturing

By embedding these parameters within the drafting environment, Microvellum prevents common errors before they can reach production. The system will flag impossible configurations, inappropriate material applications, or structural weaknesses that might otherwise go undetected until manufacturing.

Comprehensive documentation creation and management

The software’s structured approach to documentation ensures consistent information across all project outputs. From initial shop drawings to final assembly instructions, Microvellum maintains a single source of truth that eliminates discrepancies between different document types.

2D shop drawings created in Microvellum provide clear, detailed information for production that maintains consistency with the 3D model. The comprehensive documentation system includes:

- Structured shop drawing production with standardized layouts

- Detailed component specifications linked directly to the 3D model

- Organized material requirements lists with accurate quantities

- Custom reporting capabilities for specific manufacturing needs

- Direct output to production systems without manual translation

- Simplified revision management that tracks changes across all documents

- Consistent documentation standards that maintain quality across projects

The integrated nature of this documentation system offers an advantage over traditional methods where each document type might be created separately. The ability to easily create and annotate 2D plan, elevation, and section drawings ensures comprehensive documentation for manufacturing.

Improve project accuracy with our expert Microvellum millwork drafting.

Consult our experts »Microvellum’s integration with manufacturing processes

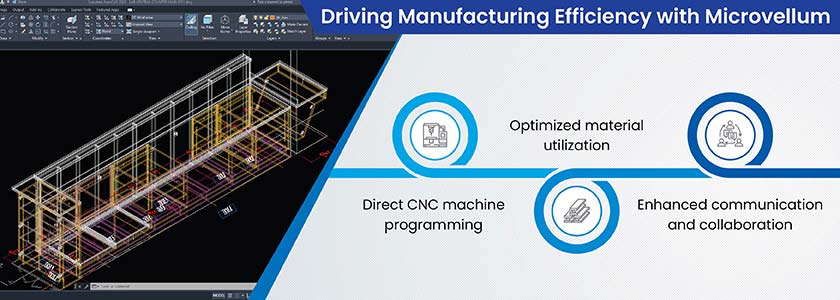

A defining advantage of millwork drafting in Microvellum is its seamless connection to manufacturing processes. This integration eliminates the disconnect between design and production that often leads to errors, rework, and delays.

Direct CNC machine programming

One of the key Microvellum speed benefits is that it directly generates machine-ready code for CNC equipment, removing the need for manual programming or intermediate translation steps. This direct path from drafting to machining ensures that what appears in the drawings is precisely what gets manufactured.

The software’s CNC integration capabilities include:

- Automatic toolpath generation based on component geometry

- Tooling selection appropriate for material and operation types

- Optimization of cutting sequences for efficiency

- Consideration of material hold-down requirements

- Validation of machining feasibility before sending to production

By eliminating the manual reprogramming required between design and manufacturing, Microvellum helps remove a major source of errors while reducing preparation time for CNC operations.

Optimized material utilization

Material costs represent a substantial portion of overall project expenses in millwork manufacturing. Microvellum’s cutting optimization features analyze all components in a project and determine the most efficient material yield, creating significant benefits for production operations.

Microvellum optimizes material use in the following ways:

- Calculating the most efficient nesting patterns for sheet goods

- Considering grain direction and matching requirements

- Accounting for saw kerf in material calculations

- Optimizing cutting sequences to minimize waste

- Maintaining design specifications while improving yield

This optimization reduces waste, lowers material costs, and contributes to more sustainable manufacturing practices all while maintaining design specifications without compromise.

Enhanced communication and collaboration

Microvellum integration helps improve communication between all project stakeholders. The platform’s comprehensive documentation ensures that everyone involved in the project from designers and engineers to fabricators and installers works from the same accurate information.

The collaborative benefits of Microvellum in millwork drafting include:

- Consistent information across all phases of the project

- Clear communication of design intent to manufacturing

- Reduced questions and clarifications during production

- Simplified coordination between different departments

- Enhanced quality control through shared standards

This improved communication reduces the misunderstandings and information gaps that occur at the handoff points between different project phases, creating a more cohesive process from design through installation

Key features that drive Microvellum’s performance for millwork manufacturers

Microvellum’s specialized capabilities provide millwork manufacturers with a powerful combination of tools and features. These features work together to create an integrated environment that supports the entire manufacturing process.

Comprehensive library system

The extensive component libraries within Microvellum contain thousands of parametric objects specifically designed for millwork applications. These range from basic cabinet boxes to complex architectural elements, all fully customizable while maintaining manufacturing standards.

Millwork professionals leverage this library system to access standard cabinet configurations for efficient design, utilize architectural millwork components for specialized applications. This also helps incorporate hardware-specific objects with proper installation details and maintaindesign consistency across projects through standardization.

For example, a millwork professional can source complex crown molding, reception desk components, wainscoting panels, and built-in wine rack systems from Microvellum’s extensive library all without creating custom elements from scratch.

Powerful customization tools

While the library system provides an excellent foundation, Microvellum drafting tools excel in customization capabilities that allow professionals to modify existing components or create entirely new ones to meet specific design requirements. This flexibility is crucial for custom millwork projects that often include unique elements.

As a custom cabinet design software, Microvellum provides the flexibility needed for both standard and custom projects. The customization capabilities include:

- Parametric modification of existing library items

- Creation of custom components that maintain parametric intelligence

- Development of specialized joinery and construction methods

- Design of unique architectural elements for specific applications

For instance, A millwork drafter can select a base cabinet from Microvellum’s library, and adjust dimensions from 30″ to 36″ wide, and all components doors, drawers, and hardware automatically updates while maintaining proper construction standards.

Integrated material management

The software’s material management system allows drafters to specify exact materials, finishes, and edge treatments for each component. This information flows seamlessly from the drafting phase to cut lists and production documentation, ensuring manufacturing accuracy.

Material management features include detailed material libraries with accurate properties, finish and edge treatment specifications with application details, material-specific machining parameters for manufacturing and accurate costing information for estimating and procurement.

For example, when a drafter specifies cherry veneer with PVC edge banding for cabinet doors in Microvellum, this instantly updates all production documents with exact material requirements, machining parameters, and updated cost estimates.

Reduce design time with smart parametric millwork models.

Learn more »Reducing errors through Microvellum’s systematic approach

One of the most significant Microvellum accuracy benefits is its systematic approach to error reduction throughout the drafting and production process.

Detailed error checking

The software includes built-in validation tools that automatically identify potential issues throughout the design process. These checks happen continuously during drafting, catching errors when they’re easiest to correct rather than discovering problems during manufacturing.

Microvellum’s error checking capabilities include:

- Dimensional validation against manufacturing constraints

- Detection of impossible joinery or construction methods

- Identification of hardware conflicts or clearance issues

- Verification of material applications for appropriateness

- Checking of machining operations against tooling capabilities

This proactive approach to error detection prevents costly mistakes from reaching the production floor, reducing rework and material waste.

Version control and revision management

Microvellum provides version control and revision management system that helps tracks changes to components and assemblies. All related documentation are updated automatically while maintaining history of modifications for reference. This ensures that all stakeholders work from current information and simplifies the change order process through systematic tracking.

This systematic approach to revisions eliminates the confusion and errors that occur when changes are implemented manually across multiple document types.

Standardized processes

By establishing standardized drafting and documentation processes within Microvellum, organizations create consistency across projects and between different drafters. This standardization reduces variability and the associated errors that often result from individual approaches to documentation.

| Standardization Area | Benefits | Impact on Operations |

|---|---|---|

| Drawing formats | Consistent information presentation and layout | Reduces review time; improves client/manufacturer comprehension |

| Detailing methods | Uniform approach to similar components | Maintains quality standards; improves production efficiency |

| Specification formats | Standardized documentation for manufacturing | Eliminates confusion; streamlines production setup |

| Process workflows | Repeatable sequences for common tasks | Increases drafting efficiency; reduces errors |

These standardized processes create a systematic approach to millwork drafting that maintains accuracy and quality regardless of project complexity or team composition.

Enhancing custom millwork efficiency with Microvellum

A leading US architectural millwork company required detailed shop drawings for a major commercial project. The client struggled with tight deadlines and needed specialized expertise to handle intricate millwork specifications.

TrueCADD’s team implemented a systematic workflow approach to address these challenges. By utilizing Microvellum’s sophisticated parametric modeling capabilities, our experts developed precise shop drawings and detailed manufacturing documentation. We utilized the software’s seamless AutoCAD integration to enhance production efficiency and generate precise machine-ready outputs.

The final deliverables led to:

- Significant reduction in production errors

- Optimized material utilization and cost savings

- Improved quality assurance throughout manufacturing

Market segments benefiting from Microvellum drafting

Microvellum for millwork offers specialized solutions across various woodworking sectors, with features tailored to different manufacturing requirements. While Microvellum for cabinetry is perhaps its most recognized application, the software serves multiple market segments each with specific requirements and benefits.

Kitchen and bath manufacturers

They leverage Microvellum’s comprehensive library of over 300 pre-built cabinet products to streamline their workflow from concept to completion. The software’s flexibility accommodates both face frame and frameless cabinetry with various joinery methods including screws, dados, cam-locks, and dowels. Extensive hardware options from top suppliers integrate seamlessly with the design, creating an efficient system for kitchen and bath manufacturers.

Closets and home organization manufacturers

Microvellum provides specialized components for walk-in/reach-in closets, pantries, and garage storage solutions. It offers options for both traditional box-style and modern 32mm system construction, with 3D rendering capabilities that enhance client presentations. The software’s integration with third-party design programs further streamlines the process for closet specialists.

Office furniture manufacturers

They utilize the versatile office furniture expansion in Microvellum’s foundation library. The parametric models allow for custom sizes, shapes, and hardware options while maintaining manufacturing standards. The software’s seamless data management from design to production adapts to varying construction methods and hardware requirements common in office furniture manufacturing.

Custom millwork products

Custom millwork operations leverage Microvellum’s flexibility for creating reception areas, bars, die walls, and store fixtures. The advanced parametric engineering tools accelerate the custom product creation process up to 70% faster than traditional methods. Source:microvellum.com

The software’s 3D model analysis capabilities ensure that even the most complex custom designs are CNC ready for manufacturing.

Conclusion

Millwork drafting in Microvellum offers a powerful combination of parametric modeling, automated documentation, and direct manufacturing integration that creates a comprehensive solution for millwork drafting.

Microvellum’s returns in terms of error reduction, manufacturing efficiency, and production precision justify the adoption for serious millwork operations facing increasingly complex projects and demanding timelines.

As the industry shifts toward more customized products, the advantages offered by millwork drafting services using Microvellum will become increasingly valuable. The platform’s ability to maintain precision while streamlining the connection between design and manufacturing positions it as an essential tool for millwork professionals committed to excellence in the growing market.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.