Accuracy in millwork takeoff is vital for woodwork contractors trying to win bids. CAD-based millwork estimating services free them from worries about errors and the manual efforts to change values.

info@truecadd.com

How CAD-based millwork estimation services save time and money

For any construction project, millwork takeoff is the key element in project budgeting and cost estimation. Millwork/joinery roughly accounts for over 20% of project costs in cold climates like that of the USA, Europe, and UK. This is true for all residential, commercial, and civil construction projects.

Correct millwork quantity takeoffs (QTOs) help general contractors and architects execute projects within budget and time, and empower them to win more bids.

Table of Contents

Millwork estimating services are especially helpful when a project involves a complex range of wood and materials. They streamline project accuracy and collaboration, where the woodwork contractor is used to working with manual methods. Usually, in these cases, a lack of specific product/design knowledge also poses a challenge. However, with professional CAD-based carpentry estimating help, cost estimation becomes easy, and both rework and wastage are reduced.

CAD platforms help overcome cost estimation roadblocks by ensuring drawing accuracy.

Benefits of using CAD-based millwork estimation

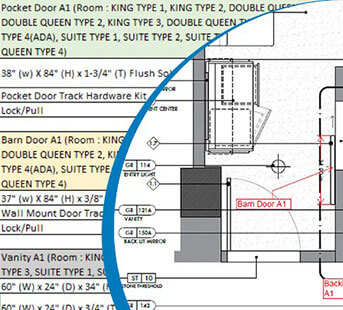

- Almost zero errors: Digital architectural plans can be used for material takeoffs with external third-party tools. The biggest challenge in calculating estimates from paper-based drawings is reading the markup or redline drawings. The information is so cluttered that knowing the exact details becomes impossible. Tools like Bluebeam can clearly markup the changes in PDF files derived from CAD drawings.

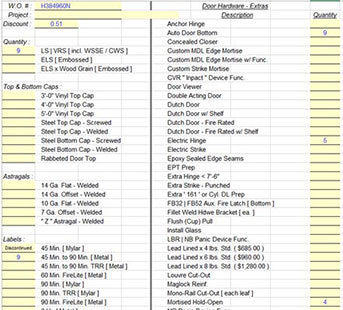

- Opportunities to leverage MS Excel: CAD drawings can be used in collaboration with MS Excel and macros by developing custom APIs. This essentially keeps manual calculation to a minimum, and everything is digitized. Tracking and rectifying errors also becomes easier.

- Accuracy in final material estimates: Once the quantity takeoffs are ready, calculating final material estimates only requires running some macros. Such an approach streamlines the process, delivers standardized documents and leaves no room for miscommunication.

- Increased estimator’s efficiencies: CAD drawings drive accuracies and promote first-time-right calculations for millwork quantity takeoffs. Thus, the senior estimator who otherwise gets caught up in extensive quality checks for manual work can save significant time.

- Increased bid-win ratio: Correct estimates empower millwork contractors to take informed decisions regarding bids they want to apply for. This way, they can channelize their efforts in bids with high probability of winning, and increase overall bid-win ratio.

How CAD-based millwork takeoffs increase accuracy

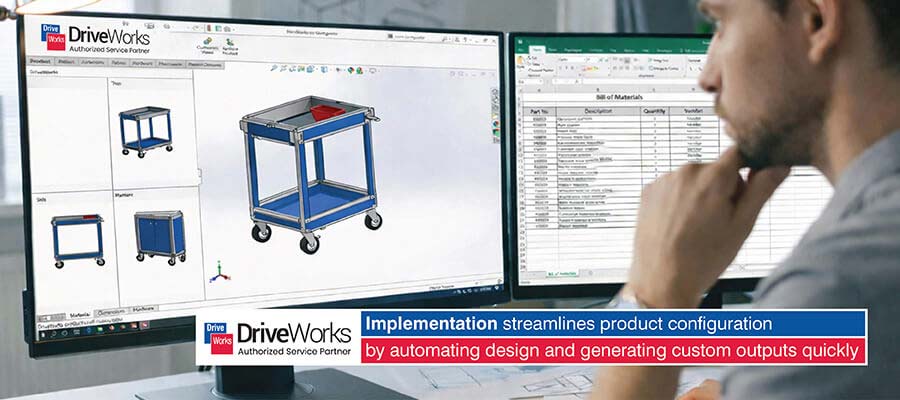

To have timely and accurate millwork estimates, it is imperative to use digital tools and automation technology. Detailed woodworking estimates help to bridge the gap in workplaces where both manual and digital designs are used. Modern estimators use 3D CAD modeling and automated BOQ generation for quick QTOs. CAD-based millwork takeoffs include precise calculations of millwork elements. These estimates can also be easily updated to accommodate any concept change.

Let us understand how the use of CAD increases efficiencies in millwork estimates to help woodworkers and contractors with a better win ratio.

1. Digitization gives a clear design idea

Millwork estimating services offer quick concept generation to derive quantity takeoffs that are quick, accurate, and timely. User-friendly digital CAD tools and technology empower millwork estimators to create or transfer construction project concepts to design.

These concepts are aligned with what architects and general contractors need. CAD tools like Inventor, AutoCAD, or SolidWorks allow quick designs using CAD environment, interoperability, and inbuilt libraries. These provide millwork designers and manufacturers with a comprehensive idea of design intent. Second, with external tools like Bluebeam, they can better interpret the cluttered markup drawings without worrying about iterations.

Digitization, thus, saves estimators from miscommunication and reduces the time taken to convert ideas into designs. The estimators can calculate and order the final millwork elements needed across the project.

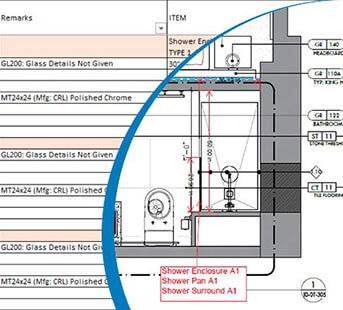

TrueCADD’s millwork estimation team helped a luxury bathroom fit-out manufacturer to accurately calculate material estimates and increase total bids placed. Using 3DAutoCAD, the team developed a unit matrix and calculated the exact quantities.

2. Ease in incorporating bespoke needs of customers

Architects, engineers, and interior designers can incorporate quick design changes into 3D CAD environments. During the concept stage, there are several iterations involved because of the cost, theme, and value of buildings. And they need to perfect the design concepts to get accurate ballpark millwork estimations.

3D CAD platforms allow updating of the concepts in real time by incorporating all the bespoke needs of customers. They capture 100% of the requirements and generate more accurate QTOs and millwork estimates. The engineer can derive a detailed QTO and automate rule-based calculations with changing inputs.

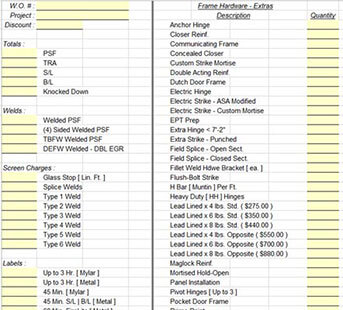

For example, QTOs at woodwork element micro levels including raw material, labor, production, and site process costs can also be done. All the rules of the millwork estimates are embedded into estimation templates. So, according to materials, quantity, and labor, the cost gets updated automatically.

A metal door and windows manufacturer needed more contracts to expand his business. But the lack of resources and lengthy estimation processes restricted their bidding. They collaborated with TrueCADD to develop accurate material estimates for the contracts on which they wished to bid. Our teams delivered accurate quantity takeoffs and material estimates to help them calculate near-exact bid values. This resulted in placing more bids and an increase in the overall bid-to-win ratio.

3. Better-informed decisions for design and materials

3D CAD tools offer realistic visualization that incorporates rendering, shapes, and sizes of different millwork elements. Their user-friendly digital environment allows designers to experiment with all trending millwork designs in a virtual world.

360-degree visualization in a 3D CAD environment helps in quicker approval of millwork design concepts. It also provides the required details of all macro- and micro-millwork elements. The engineers can also develop basic rendering of the models by assigning properties.

Conclusion

No general contractor or millwork manufacturer wants to fall behind in the construction industry. With manual estimation, they lose opportunities due to time-consuming and inaccurate calculations.

Moving away from manual estimation and adopting digital tools help them gain estimation accuracy in construction projects. Digital tools also help with faster millwork estimation. Since most millwork estimators today use modern tools, they can help you win bids with higher accuracy in millwork quantity takeoffs.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.