In 2024, the architectural millwork manufacturing industry is expected to undergo significant changes in trends and practices. To adapt to these evolving demands, millworkers will need to rethink and update their design development and drafting processes to remain current and relevant.

info@truecadd.com

Reimagining Architectural Millwork Design & Drafting to Drive Success

Table of Contents

Architectural millwork manufacturers are fine blend of tradition and innovation. Millworkers and millwork design engineers have to find the perfect blend of engineering and aesthetics during millwork design development and manufacturing.

As per a report by AIA, business conditions in the custom architectural millwork industry will continue to soften during 2024 and show a slight decline compared to 2024. The ABI score dropped to 44.3, with declines reported in all regions, although at a slower pace in the Midwest and South. Firms specializing in commercial/industrial (43.7) and multifamily residential (40.1) projects saw billings drop further, while those for institutional (49.1) dipped moderately from last month’s score of 50.1.

For architectural millworkers, it is imperative to understand the rising trends, challenges and ways to navigate them to stay profitable. Ensuring that every component is manufactured as designed is the important to have no slips in custom millwork design drafting. Final woodwork products are as flawless as woodwork shop drawings. But there are umpteen challenges in creating quality shop drawings.

Challenges in Modern Millwork Design Drafting

Since every millwork project is bespoke, both, millworkers and design engineers encounter hurdles that keep them from accelerating engineering lead time. Some millwork project management challenges include:

- Grasping contemporary design complexities: Millwork companies must understand and deliver the designs based on a deep understanding of current trends and client expectations.

- Achieving a balance between aesthetics and functionality: One of the most significant challenges is designing pieces that are as functional as they are beautiful. This involves careful detailing for manufacturing to ensure that the final product enhances the space’s usability without compromising on style.

- Cost and time constraints: Working within budget and time constraints is a common challenge. Designers must create high-quality designs while adhering to project timelines and financial limitations, often requiring innovative solutions to stay within these boundaries.

- Inter-team collaboration: Effective communication and collaboration with architects, contractors, and other stakeholders are vital. Designers must ensure that their designs align with the overall vision and practical considerations of the project.

Navigating these challenges requires a blend of creativity, technical skill, and a forward-thinking approach. For architectural millwork companies, success hinges on their ability to adapt and innovate in the face of these evolving demands. Benefits realized by outsourcing millwork shop drawings and drafting proves to be beneficial in restructuring the practice.

How millwork design drafting should evolve to reimagine custom millwork products

Reimagining millwork design drafting process is not just a technological upgrade, but a transformative journey that redefines the essence of design and manufacturing. Here are some factors that millwork design drafting should focus on:

- Integrating advanced software for comprehensive 3D modeling and 2D drafting: The integration of cutting-edge software like SolidWorks, Inventor and AutoCAD is pivotal in reimagining millwork drafting. This leap forward allows for more precise and detailed representations of designs, enabling architects and designers to explore complex geometries and intricate details with greater ease and accuracy. To state the importance of CAD drawings in millwork, use of advanced 3D modeling tools streamlines the entire process to reduce errors and save overall project time.

- Collaborative approaches between designers, architects, and manufacturers: To ensure that the design intent is communicated precisely to the shop floor, millworkers need collaborative environment. They need a close collaboration between designers, architects, and manufacturers to reduce engineering change orders and design changes. This synergy is essential for translating complex designs into tangible products by optimizing drafting workflows.

Collaboration ensures that each stakeholder’s expertise is utilized, leading to more efficient workflows, reduced production times, and higher-quality outputs. It also opens up avenues for innovative solutions and creative problem-solving, driving the industry towards new heights of excellence.

What are the software used for millwork design?

Millwork companies need to get over with their legacy 2D CAD systems that offer little scope of productivity improvement, and move to 3D parametric CAD tools. Tools that understand the design intent and offer intelligent features to compliment and expedite the millwork design process.

Inventor for millwork drafting and design

Autodesk’s Inventor®, for example, offers designers with an opportunity to create architectural content such as cabinetry, furniture, millwork, store fixtures, etc. using simplified workflows. The parametric design approach makes it easy to build the design intent for millwork designs and keeps 3D model as a ‘single source of truth’. This means that all the design data, including 2D drawings will always remain consistent, reducing errors on the shop floor.

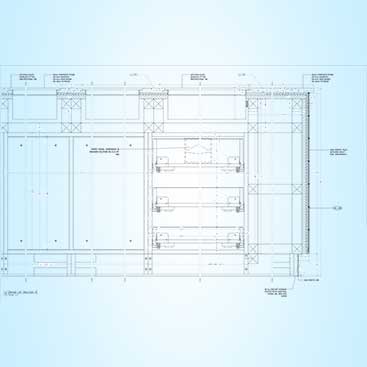

Reduced 60% design costs with detailed millwork shop drawings

CAD drafting experts at TrueCADD transformed architectural plans to detailed millwork shop drawings to enable accurate furniture manufacturing. Because of offshore team collaboration, the architectural millwork manufacturer could save time and overall project costs.

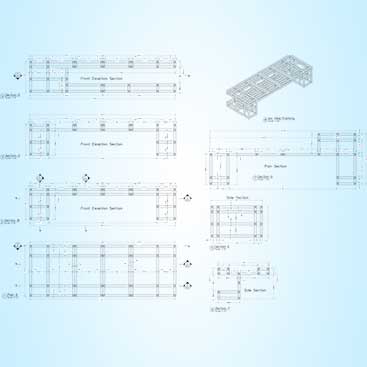

MillWork Shop Drawings

MillWork Shop Drawings

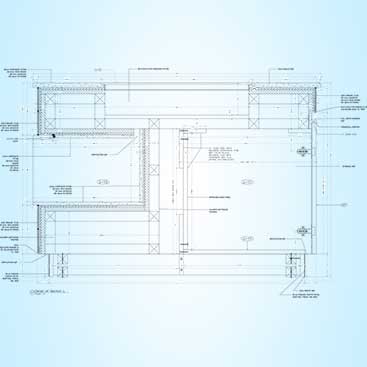

MillWork Detail Drawings

MillWork Detail Drawings

MillWork CAD Drawings

MillWork CAD Drawings

Manufacturing Shop Drawings

Manufacturing Shop Drawings

Furthermore, one-button CNC can be a reality with Inventor’s CAM feature that helps in generating CNC programs for the model geometry quickly as per the woodworking machine tools. At TrueCADD, our design engineers create lightweight models and neutral CAD file formats to suite CNC machine coding needs.

Besides, designers have access to an extensive library of hardware and materials with their own cutting data, bringing down the manufacturing cycle time significantly. On top of all these features, there’s iLogic, a technology to generate parts, models and assemblies through rule-based design. This essentially means that repetitive design tasks and configuration of basic parts can be fully automated.

SolidWorks for millwork design and drafting

SolidWorks is an equally powerful 3D CAD modeling tool for millwork and woodworking projects. Best known for its user-friendliness, SolidWorks also has a set of partner products such as PASCAM, SWOOD Design, and DriveWorks that expedite the process of developing production-ready millwork designs.

DriveWorks, for instance, is an intuitive tool to consolidate automation for ‘same but different’ millwork design elements. DriveWorks implementation shrinks the manufacturing cycle and offers an easy access for customers to configure their furniture product. This powerful tool also helps generate quotes quickly, all through automation rules that can be developed right inside the SolidWorks environment.

Discover quick tips to speed up your Millwork drafting in SolidWorks and boost your productivity today!

Explore Resource »Is technology adoption enough?

With the right tools, however, the job is only half done. A major part of the efficiency equation relies on the right skills; skills that effectively convert the architectural sketches to manufacturing-ready shop drawings. But, considering the current state of manufacturing in the U.S., this skill gap is continuously widening. As per a Deloitte survey on skills gap in the US manufacturing industry, technical and computer skills form two of the most serious skill deficiencies.

Millwork manufactures employ CAD drafting companies like TrueCADD who are proficient in delivering both 2D & 3D CAD drawings with intricate details. However, the high degree of customization required in executing certain millwork drafting services, poses severe challenges in terms of scaling production while reducing lead times.

A major roadblock to efficiency also comes in the form of training the resources and encouraging them to adopt new technology tools. While initial resistance to new technology is expected, succumbing to this pressure could be detrimental to productivity and adversely impact business bottom lines.

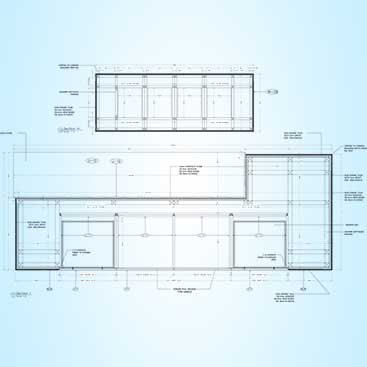

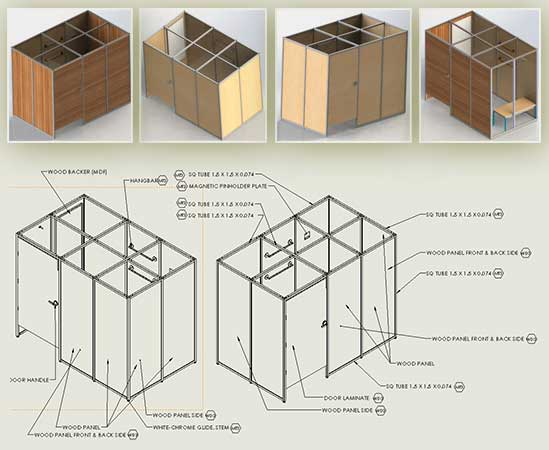

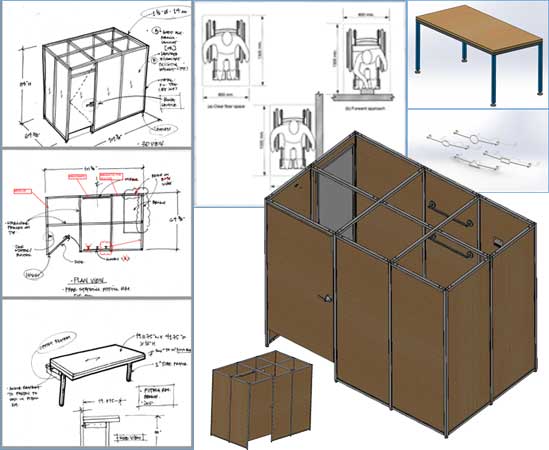

Saved overall project time with CAD drawings in millwork manufacturing

Millwork CAD drafting experts at TrueCADD transformed hand sketches into detailed drawings for a retail store’s changing room furniture. Use of shop drawings resulted in saving 45% of transportation costs and 60% design costs of the project.

3D Models and Manufacturing Drawings for Retail Store Fitting Room

3D Models and Manufacturing Drawings for Retail Store Fitting Room

Concept Drawings to CAD Detail Design

Concept Drawings to CAD Detail Design

Involving millwork design and drafting specialists

As a millwork company, the ultimate goal for you is to deliver high-quality architectural millwork that will augment the space where it will be installed. However, chances are that your team spends most of the time perfecting the design and shop drawings so that it fits well with what the architect or the contractor has envisioned. This delay significantly affects your engineer’s ability to create documents for the downstream jobs, ultimately affecting the overall manufacturing process. The right way forward to deal with this situation and eliminate the non-value adding activities is through a partnership with millwork design and drafting services providers.

While traditional drafting companies do take care of your non-core processes, millwork drafting specialists essentially extend your existing design capabilities. With a sound experience in developing design and shop drawings for a wide range of custom millwork, they complement your engineering processes and enable you to meet your business goals more effectively.

The technologically equipped millwork drafting experts work with your team in cohesion, understand your manufacturing processes thoroughly, and are well aware of the AWI standards. Whether it’s about kitchen cabinetry, retail store fixtures, custom furniture or wall paneling, they take the burden off of your in-house drafting and engineering teams when dealing with custom millwork designs.

Wrapping Up

With increasing competition from casework imports and low-priced alternatives, millwork companies must reimagine their existing design and engineering competencies. Adopting the right technology tools and enhancing the existing skillset through partnerships with specialists is the right way forward. Specialists who understand millwork and its intricacies to the core and extend the design and drafting capabilities can significantly bring down lead times and offer millwork companies a competitive edge in the market.

Partnering with a millwork drafting company offers unparalleled advantages in terms of access to an experienced pool of engineers, advanced technologies and reduced operational costs. Your association with TrueCADD for millwork drafting company gives you an access to onshore as well as offshore engineering design support to help overcome challenges.

Discuss your millwork project details with our experts today

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.