Revit® BIM-enabled precast concrete detailing addresses challenges related to installation and assembly clashes, fabrication quality, material waste and timelines. Parametric detailing, enhanced visualization and collaborative platforms of BIM drive high levels of efficiency in precast construction.

info@truecadd.com

7 benefits of BIM for precast concrete detailing for prefab construction projects

Detailing complex precast projects with traditional 2D CAD-based tools is time-consuming and expensive. Inaccuracies in calculations, constant changes, drawing oversights, data inconsistencies and inefficiencies lead to rework. Traditional 2D precast detailing tools and techniques fail to meet the speed or quality requirements of clients. They also cannot meet productivity needs in modern complex construction.

BIM-based precast concrete detailing streamlines the construction process for structural engineers, pre-casters, and prefabrication companies. Precast concrete designs, fabrication and shop drawings, scheduling and cost estimates created with BIM tools fuel higher cost-efficiency and greater constructability. BIM enhances precast concrete detailing through exact visualization of every element to achieve a higher ROI.

Conventional 2D drawings hamper efficiencies in precast construction

- Traditional detailing and documentation hinder prefab construction reliability, increase costs and delay project timelines

- High risk of leakage or honeycombing

- Lack of coordination and 3D visualization hamper clash identification and resolution leading to rework at later stages

- Material requirements extracted from conventional 2D drawings create inaccuracies and wastage during fabrication

- Absence of in-built precast concrete detailing standards and rules lead to misalignment of project scope, rework and cost overruns

- Low reliability of precast concrete detailing due to error-ridden and incomplete 2D references

7 benefits of BIM-based precast concrete detailing for prefab construction projects

Precise precast detailing and documentation with BIM-based Revit models

Structural BIM models at specified LOD provide structural engineers, prefabrication companies, and precast firms with data-rich 3D deliverables. Parametric BIM conversion of 2D CAD ensures modeling, detailing, and documentation quality with intelligent reinforcement and connections. And fabrication drawings pulled from accurate and error-free 3D models make the prefabrication process seamless.

Wall panels, beams, columns, marking plans, panel connections, inserts, etc. are detailed following industry practices. In BIM, industry codes are followed to model and detail precast as per global standards. The quality of data in the 3D BIM model ensures greater reliability, faster construction, and cost-effectiveness.

Precast concrete detailing with 3D BIM streamlines the modeling, detailing, and documentation process to ensure reliability, cost-effectiveness, and in meeting construction timelines.

TrueCADD received a Revit BIM modeling and Rebar modeling project for an office building from a leading precast manufacturing firm. A Revit structural model at LOD 450 with Rebar and BBS was to be matched with architectural and MEP models. A coordinated and clash-free 3D model was developed and delivered with accurate shop drawings and Bar Bending Schedules (BBS). Upon handover, the Revit structure model with precise documentation and complete sheet setup led to cost-effective precast products and desired project outcomes.

Informed decision-making and clash-reduction with 3D model coordination

A precast concrete project includes various elements like columns, beams, floors, walls, stairs, facade panels, double walls HCS, etc. With a structural 3D model that combines architectural and MEP models, pre-construction and pre-emptive clash identification and resolution can be carried out reliably. Consequent early involvement of precast and prefabrication teams generates real-time feedback for effective clash resolution through 3D model coordination.

An error-free 3D model aids higher accuracy in precast detailing for shop drawings, panel elevations, marking plans, lists of cast-in components, etc. Such a coordinated 3D BIM model saves much rework, mitigates project delays, and promotes a seamless installation of precast elements on site.

Precise BOMs and BBS for quality fabrication and onsite coordination

Coordinated 3D BIM models carrying a list of all precast elements with sections and views improve the erection of structures. Bills of Materials (BOMs) extracted from 3D models and accurate Bar Bending Schedules (BBS) help precast manufacturers with precise counts of production materials and lists of elements. Rebars can be automatically numbered, and drawings with bending schedules generated rapidly from the 3D Rebar models.

The representation of panel connections, elevations, inserts, brackets, etc. in 3D geometry with AR provides an immersive experience. The higher construction visibility gained by comparing data-accurate shop drawings, erection drawings, and 3D models improves onsite coordination. The presence of precise BOMs also leads to a significant reduction in material waste and overall project costs.

A precast manufacturer needed a 3D BIM model at LOD 450 for a residential project in UAE. The team at TrueCADD created a clash-free coordinated 3D model with accurate Rebar shop drawings of concrete elements, BBS. This enabled the client to gain precise precast element manufacturing and onsite installation.

Insert and analyze connection details for pre-cast joints via 3D models

3D precast detailing with complete IFC integration speeds up the entire pre-casting process. Streamlining the 3D design process with real-time updates also improves onsite assembly.

3D BIM modeling driven by automation tools like Dynamo, plugins, or APIs can be used to deploy pre-defined rules. This promotes higher quality and speeds up 3D modeling, detailing and shop drawings. Customized Revit families or assemblies for precast elements used within the 3D model lead to improved prefabrication and precast detailing.

Better precast concrete detailing and finishing for pre-configured components

3D Revit BIM models help in detailing precast elements like placing rebar, auto-format dimensions in shop drawings etc. by streamlining the 3D design processes. Accurate 3D BIM models loaded with customized Revit families enhance precast product customization. A graphical representation of precast elements in 3D with exact material types and dimensions improves the detailing and finishing of the final product. Precise mould drawings ensure there is no leakage or honeycombing. The superior casting of concrete elements ensures better finish and no material wastage.

3D models with LOD 450 and Rebar template modeling backed by a full-sheet setup produce cost-effective outcomes and deliverables.

Hassle-free erection of structures with higher visualization of precast BIM models

3D Revit models provide a 360-degree view of the precast elements and components. These views make it easier to add required fabrication pre-casting details and annotations like unique erection ID, and element ID. Even details such as the exact points for reinforcement cutting and bending machinery can be obtained.

Shop drawings, erection drawings, set-out plans, mould drawings, panel elevations, etc. pulled from coordinated and clash-free 3D models facilitate flawless detailing. The accurate and complete dataset of drawings, documents, etc. improves fabrication accuracy and quality. This reduces rework and mitigates project risks.

Complete structural coordination and extraction of technical data from a single Revit model is also used to visualize connection details and produce accurate BBS. These systems include panel detailing for curtain walls, concrete wall systems, precast wall panels, precast joinery, stairs detailing, etc.

Improved collaboration with BIM 360® and 4D construction sequencing

Early coordination of various disciplines such as architecture, structure, and MEP leads to improved collaboration. Adding timelines and scheduling details to the precast concrete model allows manufacturers to plan material purchasing, manufacturing process duration and delivery schedules. They can also plan element storage for site delivery, precast element storage and execution processes.

Streamlined collaboration in the pre-construction stage also reduces the need to generate costly RFIs during actual construction. 3D BIM models reinforced with 4D sequencing or scheduling promote improved visualization of precast materials, resources, etc. for erection.

Early involvement of precast and prefabrication teams in the preconstruction stage speeds up 3D model development. The use of cloud-based platforms like BIM360 improves storage, access, and sharing of 3D models, drawings, and other documentation in real time.

Optimizing design and fabrication workflows through Revit with Dynamo

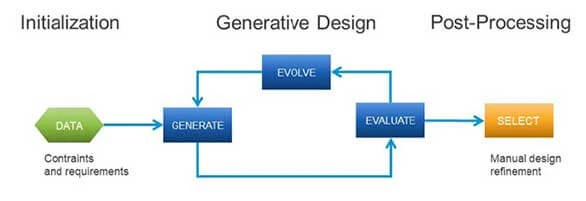

Computational or generative design supports design and fabrication automation. Dynamo powers such computational design to produce a wide range of ideas, options, working scenarios, and performance simulations. With these BIM-based tools multiple prototypes can be quickly generated to achieve desired outcomes and optimized designs.

Dynamo helps in the selection of the best element from a set of available criteria. Combining multiple factors to resolve design and fabrication challenges with Dynamo can help structural engineers find the optimal solution reliably.

Optimization of design and fabrication includes various techniques such as genetic algorithms, initialization, selection, genetic operators, etc. Here, Dynamo can be used to find the best truss configuration to define geometry and create spatial truss. It can also perform deformation analysis, solve truss geometry behaviour, and more.

Conclusion

Precise detailing and documentation, smarter processes, and streamlined collaboration across multiple teams are the main advantages of BIM-based precast concrete detailing. With precise reinforcement designs, size and shape of elements, pouring and settling timeline, etc. precast manufacturing becomes easy and quick.

BIM tools allow greater automation of complex processes and superior usage of data from 3D geometry while creating a significant increase in ROI. Software-driven BIM helps structural engineers, pre-casting firms, and prefabrication companies gain a competitive advantage in the AEC industry.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.

Read more here

Read more here