SolidWorks sheet metal modeling remains the top choice for design engineers and fabricators for its features and functionalities. Here are the top five tips you can use to efficiently model sheet metal parts in SolidWorks.

info@truecadd.com

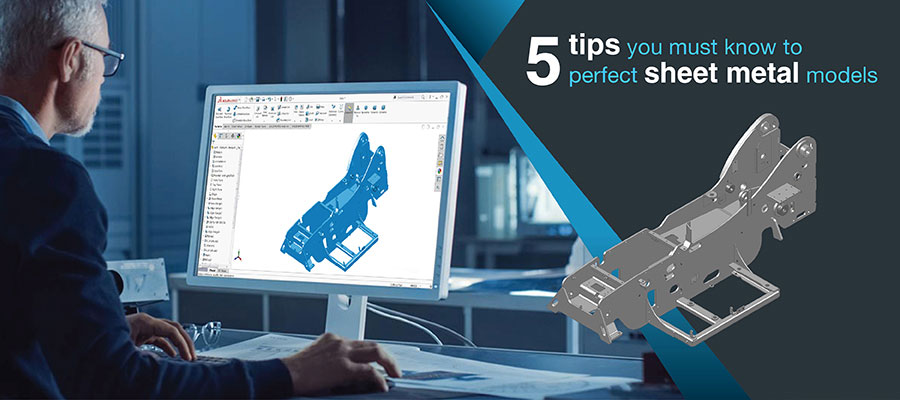

Top 5 Tips for Efficient SolidWorks Sheet Metal Modeling

Sheet metal fabrication needs a constant check to ensure that the manufacturing is as per the actual design briefs shared. Fabrication processes like bending, welding, and punching, if carried out without proper design intent understanding, increases scrap and rework.

To enhance overall fabrication efficiency, designers and fabricators have adopted 3D sheet metal modeling as a primary platform for design communication. 3D CAD tools address design complexity by breaking down the assembly into part drawings and sub-assemblies. Modern 3D parametric CAD platforms further optimize the design concepts and create production-ready designs.

Why use SolidWorks for sheet metal modeling?

SolidWorks offers an array of specialized features to develop complex sheet metal assemblies. For example, the sheet metal module in SolidWorks offers tricks, shortcuts, and automatic commands to create specific sheet metal features.

Major benefits of using SolidWorks for sheet metal modeling include:

- Flexibility and speed in designing sheet metal components and part assemblies

- Standardized and structured 3D CAD part modeling and assembly approach

- Guided and intuitive sheet metal modeling approach, providing high accuracy

- Consideration of multiple aspects of design development using DFMA approach

- Workflow-based collaborative environment to share designs, and decision making

- Addition of automation to speed up product design development and quality

Because of these benefits and many others, SolidWorks has become the most popular CAD design and drafting platform across the industry. Hence, we bring you some tips to model sheet metal parts in SolidWorks.

Top 5 Tips for Efficient SolidWorks Sheet Metal Modeling

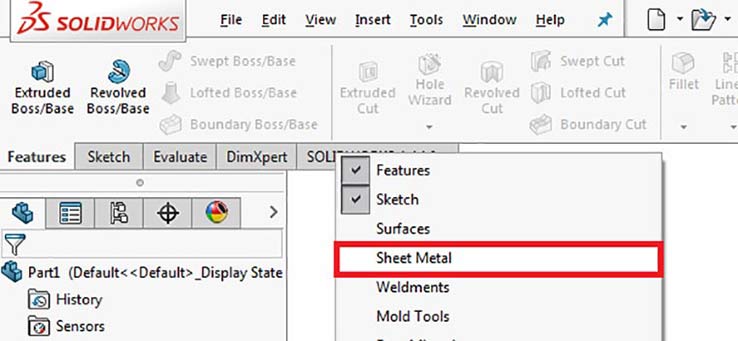

1. Start with the sheet metal module in SolidWorks

As a 3D CAD modeler, you are free to sketch anything in the CAD environment. However, an understanding of optimizing raw materials usage during manufacturing takes you to the next level. It gives you the power to build 3D CAD models that accurately fit production pipelines and provide positive outcomes.

When you design a metal component made from thin plates or sheets, assign it as sheet metal part in SolidWorks. The platform will then start the specialized module for sheet metal by fetching the suitable properties. So when a designer initiates drafting, SolidWorks automatically adds special instructions for sheet metal product design.

Sheet Metal Module in SolidWorks

Sheet Metal Module in SolidWorks

Create your fabrication assembly of various parts using the weldments module if the assembly needs welding and structural parts.

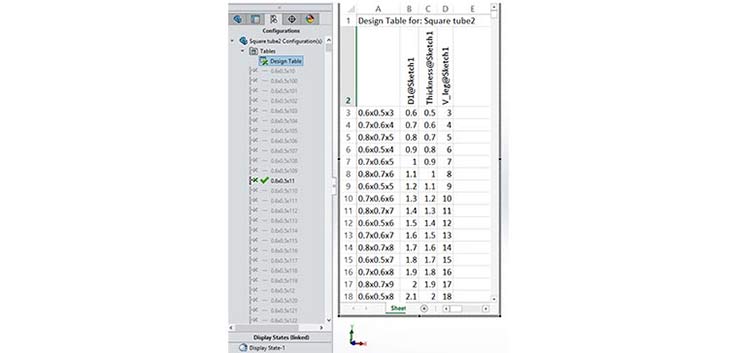

The weldments module allows creating structures with only a few sketches in 2D or 3D. The final models are then generated by customizing pre-loaded shapes. By default, it automatically creates two configurations of machined parts and welding parts.

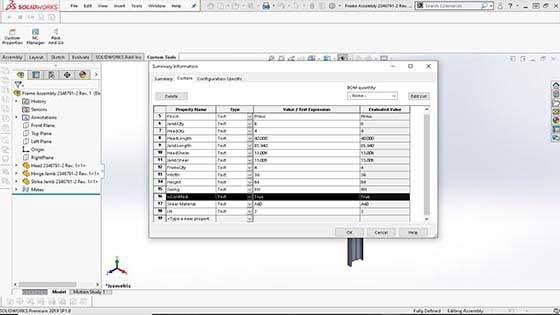

With the use of the design table, one can have many configurations of structural channels and tubes. These can then be stored in the CAD library as standard product models for reuse. And the users can save hundreds of such standardized configurations using the design table. They can create structural sheet metal part families, along with specifications regarding shapes, sizes, thicknesses and materials.

Configurable Custom Weldment Profiles in SolidWorks

Configurable Custom Weldment Profiles in SolidWorks

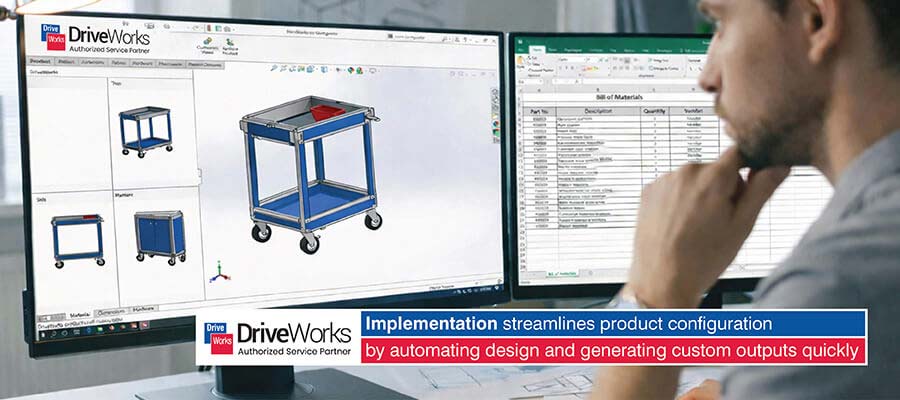

SolidWorks drafting for sheet metal product design guides the user throughout the assembly development and spares design and/or modeling reworks. It also helps capture all the DFMA requirements into your model accurately via an intuitive and flexible sheet modeling CAD environment. It can further be integrated with external databases, such as Excel spreadsheets, to automate CAD models.

Lengthy product design times and an erroneous design cycle became challenging for a leading doors and frame manufacturer. They used Excel spreadsheets with SolidWorks CAD models to automate design customization, and reduced design time from 15 days to a few hours.

Automated Door Design Customization

Automated Door Design Customization

2. Leverage SolidWorks flexibility for complex sheet metal shapes

The CAD designer or the engineer might not have the opportunity to start with the sheet metal module every time. In this scenario, one can start with the free form concepts of 3D solid models and surface creation. These models can then be converted into sheet metal models using the shell function omt-3f SolidWorks with relevant thickness.

Sheet Metal Options in SolidWorks

Sheet Metal Options in SolidWorks

For example, a model of a hopper of an SPMs, or a duct of an HVAC system, goes through multiple steps when using the sheet metal module. But if it is done using a standard 3D CAD environment and then converted, the steps required for modeling are reduced and simplified.

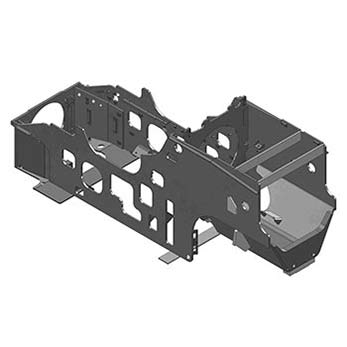

Complex Sheet Metal Designs

Complex Sheet Metal Designs

Sheet Metal Designs

Sheet Metal Designs

3. Create parts with constant sheet thickness and K factor

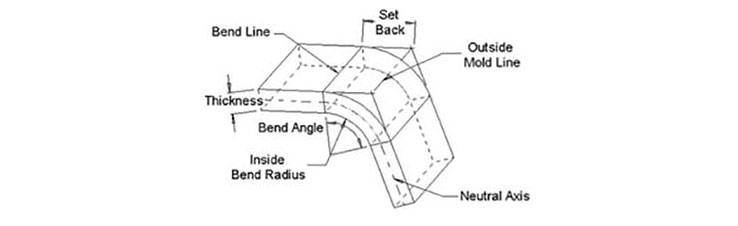

Most parts are fabricated either from sheets of metals like steel and alloys, aluminum, copper, bronze etc., with appropriate thickness. The springback factor or “K” factor is required to develop the sheet metal parts to achieve perfect bends and to find out unrolled/flattened size of metal parts.

Sheet Metal Understanding K Factor

Sheet Metal Understanding K Factor

In SolidWorks sheet metal modeling, one can choose the material, thickness and K factor from the inbuilt material library. The user can also add user-defined material properties.

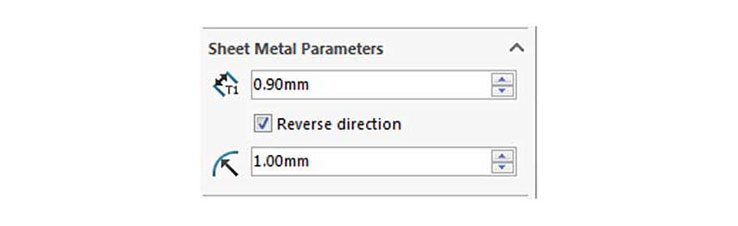

If no gauge table is used, the thickness of the material and bend radius can be entered in the sheet metal parameters. Here the user can also choose to reverse the direction, which determines on which side of the sketch the material is applied. The SolidWorks user interface also shows arrows to guide the users.

Sheet Metal Parameters

Sheet Metal Parameters

In the bend allowance section, one can select how SolidWorks finds the neutral axis to auto-calculate flat patterns. By choosing the K-Factor, bend allowance, or bend deduction from the pull-down menu, specific values can be entered.

4. Parametric model for welding and hardware details

Use of SolidWorks parametric modeling for large sheet metal assembly saves a lot of time while modifying the design intent. Designers can use a top-down approach for assembly creation to save time on updating designs while changing any parameters of a part or parts in sheet metal assembly. Such detailed drawings help address multiple concerns of sheet metal fabricators including communicating design essence.

You might think 4-5 clicks isn’t time-consuming, but if you’re working on dozens of pieces of hardware at once, all those clicks add up to valuable time. Leveraging an efficient approach with SolidWorks that involves dragging and dropping hardware so that it auto-snaps into the appropriate holes helps to save that time.

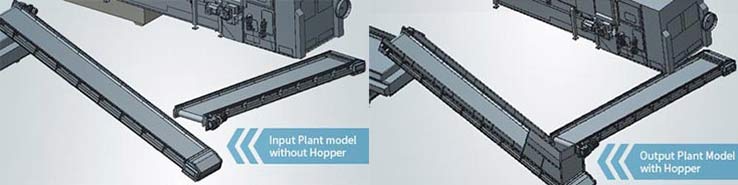

Lengthy and error-prone design cycles for hoppers delayed delivery timelines for a designer and manufacturer of recycling plant products from Ireland. We collaborated with their design team and developed parametric CAD models for hoppers for large assemblies. The partnership resulted in delivering 55 hoppers per month and provided expansion opportunity for the client.

Hopper Model

Hopper Model

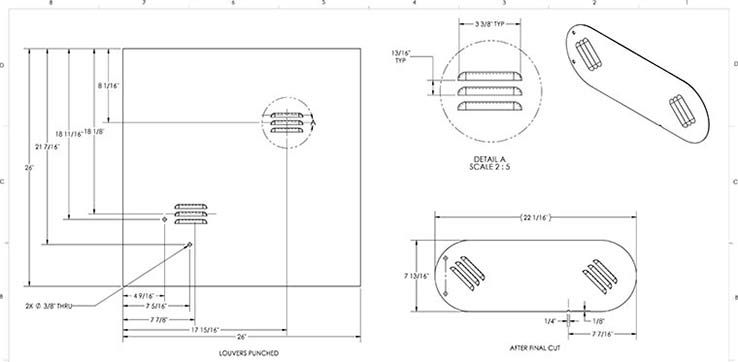

5. Begin by considering center and symmetry

Any CAD software allows the designer to start the sketch from any plane and from any position. However, the design engineer must know that all digital sheet metal models are for direct manufacturing use in an integrated environment. So, for precision, the designer has to ensure that all the coordinate systems of CAD match with those of the CNC machines. For example, the plane origin in SolidWorks must align with that of the CNC cutter or CNC press.

Sheet Metal Exercise in SolidWorks

Sheet Metal Exercise in SolidWorks

Here, if a modeler uses the symmetry, it will save a lot of manufacturing time. And many adjustments like the setting up of home positions of cutter and positioning of raw sheets to cut the metal parts, and doing optimized nesting can be done quickly.

Also, one can use techniques like mirroring and mating while 3D modeling to effectively use the symmetry. Much manufacturing time can be saved with this simple approach when starting with the sheet metal model. It offers more flexibility and freedom from the start of the design process and prevents rework.

Conclusion

Use of 3D CAD tools helps metal fabricators to be more competitive and efficient. But SolidWorks parametric modeling takes it to a whole new level. With the right approach in sheet metal modeling and use of dedicated SolidWorks modules, fabricators, designers and modelers can improve overall efficiencies.

We hope the tips mentioned here will help you save time and costs and make your sheet metal designing more organized and productive.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.