How well you evaluate your potential BIM partners on critical criteria such as expertise, collaboration, technology, references, and compliance, defines the success and profitability of your BIM projects.

info@truecadd.com

5 Aspects to Consider Before Selecting a BIM Partner

AEC firms have been adopting and implementing BIM to create increasingly productive and economical setups. But the continually changing standards, regulations, infrastructure requirements, team training needs, and the complexity of data management often lead to sub-optimal use and implementation of BIM, if not handled by experts. This is where a BIM outsourcing partner plays the role of enabler, especially in leveraging BIM for small AEC firms.

Table of Contents

However, the booming BIM market, projected to reach USD 14.68 billion by 2028 has led to a proliferation of BIM service providers, making it confusing to select one that suits your requirements and objectives most closely.

This is why, in this article, we have discussed the five key aspects you need to be aware of when selecting a BIM partner: from scrutinizing BIM capabilities and infrastructure to legal compliance considerations. Whether you’re seeking to outsource BIM work or avail Revit services or looking for a reliable BIM Outsourcing Company or Contract Partner, this guide will help you make the right decision.

Five Aspects to Consider Before Picking a BIM Outsourcing Partner

By exploring the five critical aspects of selecting a BIM partner, including experience and expertise, collaborative approach, technology and tools, track record and references, and regulatory compliance, organizations can create value-driven and long-term BIM provider partnerships.

BIM Experience and Expertise

Choose a BIM partner with a strong track record and relevant experience in your industry and project type. Experience empowers a BIM partner to tackle challenges and foster innovative solutions that enhance project outcomes.

Check the Relevant Experience: Don’t just go by how long the possible BIM partner has been in business, but also how long they have been offering the services you need.

Industry Experience: Selecting a BIM partner with a proven industry track record in BIM design and BIM construction is crucial, as their experience provides insights into sector-specific challenges and requirements and enhances project outcomes.

Team Competency: Check out the skills and abilities of the people on their team. A qualified and skilled team can make a big difference in the success of a project. Look for Autodesk Certified Professionals (ACP) or Building SMART certifications.

Project Management Skills: Assess their project management proficiency, as it is crucial for BIM partners to efficiently plan, execute, meet deadlines, and adhere to budgets.

Quality Control and Assurance: Ask about their quality assurance procedures, as a dependable BIM partner should have established protocols to guarantee the precision and quality of BIM models and data.

Flexibility and Scalability: Assess their ability to adapt to changes and scale up or down as needed during the project’s lifecycle.

Alignment with Project Goals: Confirm that your BIM partner shares your project goals and is committed to achieving them.

Prioritizing experience and expertise in your choice of BIM partner is the foundation for successful, efficient, and high-quality project delivery.

In just two months, our team completed a 4D BIM simulation project, enabling the architectural firm to enhance design communication, achieve substantial cost savings, and significantly reduce rework through sequential video presentations.

Collaboration and Communication

Look for a partner who can effectively collaborate with your team. A cooperative and communicative relationship is essential for project success. When evaluating a BIM partner’s collaborative approach, consider these key points to include in your assessment:

Communication: Evaluate the partner’s communication methods and tools, as effective and transparent communication is vital for keeping all project stakeholders informed and in sync.

Integration with Stakeholders: Examine the partner’s ability to integrate seamlessly with other project stakeholders, including architects, engineers, contractors, and clients. Look for partners who employ the Level of Development (LOD) approach to enhance collaboration, ensuring that project stakeholders have access to the right level of detail at each phase, optimizing communication and decision-making.

BIM Collaboration Software: Assess how the partner utilizes BIM collaboration software platforms like BIM 360 or Trimble Connect, as these platforms enable real-time collaboration and data sharing among project participants.

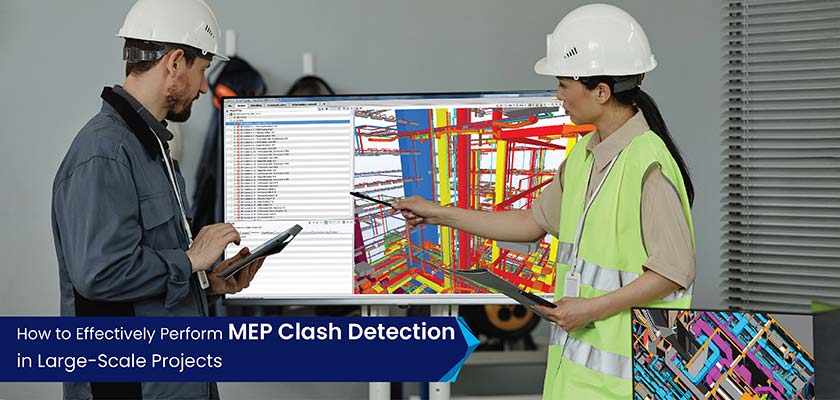

Coordination of BIM Models: Examine how the partner manages the coordination of BIM models across diverse disciplines, as their expertise in identifying and resolving clashes is essential for early conflict resolution in the project.

Regular Meetings: Review the frequency and format of project meetings. Consistent meetings support collaboration, provide progress updates and offer a platform to address concerns.

Feedback Mechanisms: Examine how the partner seeks and responds to feedback from project stakeholders, showing their dedication to ongoing improvement through feedback integration.

Documentation and Reporting: Verify that the partner maintains comprehensive records of project decisions and actions, as these well-documented records aid in tracking progress and serve as valuable references for resolving disputes.

A robust collaborative approach sets the foundation for seamless teamwork, effective communication, and efficient coordination, ultimately driving the success of BIM projects.

BIM Technology and Tools

A BIM partner’s expertise with advanced technology and tools forms the cornerstone of streamlined processes and enhanced project outcomes, demonstrating their commitment to staying at the forefront of industry innovation.

Consider the following key aspects:

BIM Software Proficiency: Evaluate the partner’s competence in using BIM software tools, including but not limited to Autodesk Revit, AutoCAD, Navisworks, and similar applications. Their expertise in these tools is fundamental to smooth model creation, collaboration and data sharing.

4D and 5D BIM Capabilities: Ask about their proficiencies in 4D (time-based) and 5D (cost-based) BIM applications. Look for partners who create precise 4D BIM models in Revit®, incorporating accurate data from multiple sources, project managers, and planners, ensuring their clarity and resilience. A partner well-versed in these aspects can significantly improve project scheduling and cost estimation.

Clash Detection and Resolution: Examine their strategy for detecting and resolving clashes with the help of tools such as Navisworks or Solibri. Efficient clash resolution plays a vital role in reducing conflicts and interruptions during the construction phase. Look for services that include thorough model analysis, ensuring seamless and error-free project execution.

Laser Scanning and Point Cloud Data: Evaluate their proficiency in using laser scanning technology and processing point cloud data to produce precise as-built models. This technology holds significant value, particularly for renovation and retrofit projects.

Mobile and Field Technology: Assess their use of mobile and field technology for on-site real-time data capture, which plays a pivotal role in project monitoring, issue tracking, and ensuring quality control.

BIM Libraries and Templates: Assess whether the partner has a library of BIM components and templates that can streamline model creation and maintain consistency across projects.

Augmented Reality (AR) and Virtual Reality (VR): Explore their integration of AR and VR technologies for enhanced project visualization, client presentations, and design reviews.

It’s crucial to verify that your chosen BIM partner has access to the latest BIM software and tools. The adoption of cutting-edge technology has the potential to streamline your project processes and elevate the overall project results.

TrueCADD developed a clash-free 3D BIM model, exceeding the capabilities of traditional CAD software. This model empowered our client to analyze energy efficiency, leading to substantial cost savings of 30% to 35% during the construction of a healthcare facility.

References and Past BIM Projects

Looking into a BIM partner’s references and past projects gives you a first-hand look at their track record and skills, which is very helpful for making an informed choice. Review their portfolio and speak with past clients to gauge the quality of their BIM work and their reliability.

Client Testimonials and References: Reach out to former clients to collect feedback on their satisfaction with the partner’s services and evaluate the partner’s effectiveness in collaboration, communication, and problem-solving during past projects.

Project Portfolio: Examine the partner’s project portfolio, with a focus on both the range of projects they’ve handled and those that align closely with your project’s specific scope and needs. Successful BIM projects across the industry showcase the transformative potential of this technology.

Reputation and Industry Recognition: Research the partner’s industry reputation by examining online reviews and ratings and assessing their receipt of awards, certifications, or recognition for their achievements.

Timeliness and Budget Adherence: Ask about their track record in meeting project timelines and budgets, ensuring a history of timely completion and financial responsibility.

Quality of Work: Inspect the precision and quality of their BIM models and project deliverables while considering the thoroughness and level of detail in their previous works.

A comprehensive evaluation of references, past projects, and reputation will provide the assurance needed to select a BIM partner with a proven track record of delivering successful and dependable outcomes.

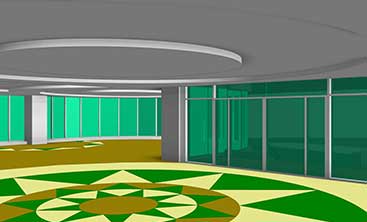

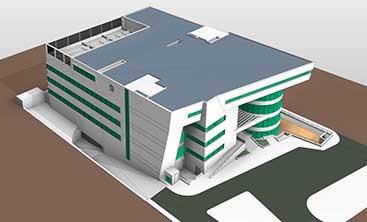

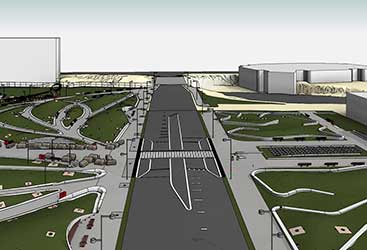

Our 3D BIM model prevented reworks and material waste, enabling structured planning, cost savings, and enhanced safety for the client’s public-business infrastructure project. It also provided accurate BOQ/BOM estimates for floor paving and equipment.

Legal and BIM Standards Compliance Considerations

Evaluating legal and BIM standards compliance ensures a BIM partner’s ability to navigate regulatory complexities and minimize project risks. Here are important points to consider:

Licensing and Certifications: Confirm that the BIM partner possesses the essential licenses and certifications required in their region to provide BIM services and validate the legitimacy of these credentials.

Contractual Agreements: Review their standard contracts and agreements to ensure they are fair, legally sound, and protect the interests of all parties involved, including dispute resolution mechanisms.

Data Privacy and Security: Confirm that the partner has data privacy and security measures in place to protect sensitive information and comply with data protection regulations, such as the GDPR or HIPAA, where applicable.

Intellectual Property Rights: Discuss intellectual property rights, including who owns the BIM data and models, and ensure these are clearly defined in contracts to prevent any disputes in the future.

Health and Safety Compliance: Ensure that the partner complies with health and safety regulations on construction sites, which can impact the safety of workers and the public.

Ethical Practices and Codes of Conduct: Evaluate the BIM partner’s commitment to upholding ethical standards and industry-specific codes of conduct, verifying their adherence to integrity and ethical values in their professional undertakings.

By evaluating these points, you can gain confidence that your chosen BIM partner is committed to legal and ethical compliance, reducing the risk of potential legal issues and ensuring a trustworthy and reliable partnership.

As a BIM service provider, we offer a wealth of experience, advanced technology expertise, and a history of successful project delivery. Our collaborative approach ensures that your unique needs are met efficiently. We prioritize compliance with industry standards and regulations.

Select a partner committed to excellence.

Types of BIM Services that are Commonly Outsourced

BIM offers a spectrum of services, including architectural design, structural engineering, MEP (Mechanical, Electrical, and Plumbing) coordination, clash detection, 4D scheduling, and facilities management, revolutionizing the entire lifecycle of construction projects.

Here are some common types of BIM services:

- BIM Modeling: Creating 3D digital models of construction projects.

- Architectural BIM: Detailed architectural model creation and visualization.

- Structural BIM: Detailed structural modeling and analysis.

- MEP BIM: Mechanical, electrical, and plumbing system modeling.

- Coordination & Clash Detection: Identifying conflicts between building components.

- Quantity Takeoff & Estimation: Calculating material quantities and project costs.

- BIM Implementation & Training: Setting up BIM workflows and training staff.

- Facility Management: Using BIM for post-construction facility management.

- Scan-to-BIM: Converting laser scans to BIM models for renovations.

- BIM Consultation: Offering advice on BIM best practices and strategies

- Industry Compliance: Ensuring BIM models meet regulations and standards.

- Project Management: Overseeing the entire BIM project from planning to execution.

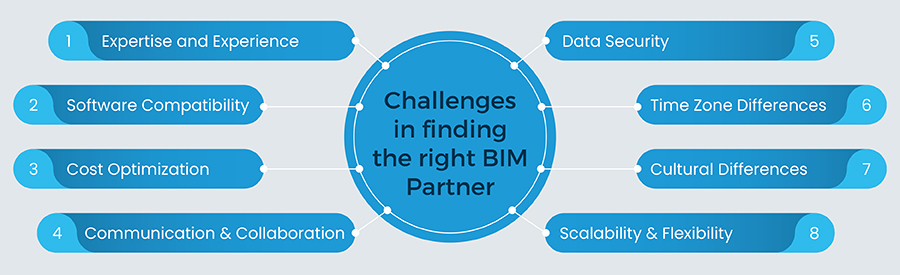

Challenges in Finding the Right BIM Partner

Finding the right BIM partner can be challenging for various reasons. Here are some common challenges:

- Expertise and Experience: Ensuring the partner has the relevant BIM expertise and experience.

- Compatibility: Finding compatibility between your partner’s BIM tools and software with your own.

- Cost: Balancing the cost of outsourcing BIM services with the quality of the work.

- Communication: Effective communication and collaboration with a remote BIM partner.

- Quality Control: Maintaining consistent quality standards for BIM deliverables.

- Data Security: Ensuring the security of sensitive project data and intellectual property.

- Project Timelines: Meeting project deadlines.

- Geographical Distance: Dealing with time zone differences.

- References and Reviews: Finding reliable references and reviews for potential BIM partners.

- Cultural Differences: Dealing with cultural differences and work practices.

- Scalability: Ensuring that the partner can scale up or down as per project requirements.

- Technology Updates: Ensuring that the partner stays up-to-date with the latest BIM technologies.

- Client Compatibility: Ensuring that the partner aligns with your project goals and values.

Conclusion

In the journey to find the perfect BIM services partner, it’s crucial to consider various factors carefully. Whether you are a BIM technical firm, design firm, or contract partner, the selection of the ideal BIM outsourcing partner is a decision that can profoundly influence your project’s outcome.

By evaluating their experience, approach to collaboration, technology and tools, track record, and commitment to legal and compliance standards, you can make an educated decision. Your chosen BIM outsourcing company should align with your project’s unique needs, contributing to its efficiency, innovation, and ultimate success. By using the comprehensive approach outlined in this article, you can ensure the selection of a BIM partner that aligns with your project requirements and contributes to its successful completion.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.