MEP BIM coordinated models deliver deep collaborated insights into design and constructability issues for all stakeholders. Through enhanced visualization of the MEP ecosystem, they enable early inter-disciplinary clash-identification and resolution, driving optimized building system designs.

info@truecadd.com

Improving Building Design & Quality Using MEP Coordination

Design and installation of MEP systems are one of the more complex construction processes, calling for a high level of detailing and synchronization. Building design and quality problems including interdisciplinary clashes hit building contractors when the MEP layouts do not fit into the final design.

Accurate content-rich MEP BIM models help effective and optimized layout for fabrication and installation of MEP equipment. Early conflict detection and resolution facilitated by an MEP coordinated model also improves spatial coordination and constructability of a building. Being able to visualize the results in three dimensional coordinated MEP spaces helps building contractors build a unified MEP ecosystem.

Collaboration between architectural, structural, and MEP trades through three dimensional BIM models keeps everyone on the same page on design insights. Extraction of shop drawings from a coordinated Revit® BIM model drives improved fabrication and installation of MEP components, ensuring structurally sound and sustainable buildings.

In this blog, we talk about the factors affecting the building design and quality of MEP systems and how MEP BIM coordination improves building design and quality.

Factors affecting the design and quality of MEP systems

For complex and large-scale construction projects, building contractors are often challenged with issues such as modifications to MEP systems after designs have been approved. Even minor changes can result in inaccurate MEP layouts, impacting the overall construction. For instance, large equipment placed later on in an already spatially coordinated area, can lead to design and quality failure.

Here are some factors affecting the building quality and design of MEP systems

- Traditional 2D drawings or sketches

- Inaccurate, or missing design details in Mechanical, Electrical, Plumbing and Fire 2D drawings

- Lack of coordination between MEP trades

- Design clashes between mechanical, electrical, and plumbing

- choice of building materials

How MEP BIM coordination improves building design and quality

Defining conflicts at the design stage through 3D MEP coordination eliminates clashes later on during the actual onsite construction. It enables efficient and integrated project delivery for better building.

MEP coordination ensures proper placement of equipment, electric conduit, ceiling, elevations and support systems, insulations, wall openings, etc. which ultimately results in hassle-free onsite installations. Through coordinated processes and workflows, contractors can mitigate risks of wasting material and labor, increase site safety, and meet deadlines for onsite installation with better accuracy.

MEP coordinated models ensure accuracy in design constructability

Design or content validation lays a strong design foundation in the preconstruction stage. Building a coordinated 3D model in Revit with parametric capabilities enables real-time modification tracking. Being able to access and share updated model content that includes elevation, sections, views, LOD, etc. ensures design accuracy is upheld.

2D CAD to 3D conversion with information-rich 3D models promotes greater design performance. Difficult to visualize or cramped up spaces are better represented with realistic components using accurate annotations and dimensions.

Nearly 61% of MEP trades use BIM for constructability evaluation and to make better design decisions regarding inter-disciplinary clashes.

3D coordinated MEP model at LOD 300 improves design constructability for a healthcare facility, Australia

An MEP BIM modeling project was outsourced to TrueCADD for Hospital construction. The client required a 3D coordinated BIM model at LOD 300. With 2D plumbing drawings provided as project input, the team at TrueCADD built a coordinated 3D model for plumbing layout and hydronic equipment. Detailed drainage systems for upper and underground drainage were visualized and validated to make informed decisions for improved design constructability.

Detailed MEP 3D Model

Revit MEP 3D Modeling

3D MEP models reduce design errors between trades with greater visibility & coordination

Individual trades such as mechanical, electrical, and plumbing integrated into one federated model improve coordination. Checking for various design inconsistencies in a 3D environment drives greater visibility. Real-time walkthroughs enriched with AR/VR assist building contractors to visualize the dimensions and location of MEP equipment. Ambiguities can be identified, highlighted, and resolved to improve coordination outcomes.

3D modeling and coordination of various systems such as HVAC ducts, mechanical piping, electrical components, sanitary systems, fire protection systems, etc. promote informed decision making. Clear and accurate visualization of essential spaces for MEP installation for room layout, ceilings, riser locations, etc. reduces design errors between multiple trades.

Early clash resolution eliminates rework leading to better design performance

Rework points to inefficient design and inferior building quality. Ignoring MEP clashes in the design stage can lead to design failures at every project stage. 3D MEP coordination eliminates the need for rework through pre-emptive clash detection and resolution. Disconnected MEP systems can create a serious malfunction in the overall performance of the building. Identifying soft, hard, and workflow clashes and storing them in viewpoints accelerates the clash detection process whilst realizing greater design performance.

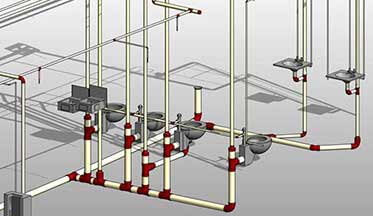

Clash-free MEP model reduces rework for a commercial project, USA

TrueCADD were outsourced an MEP BIM modeling project to create a coordinated BIM 3D MEP model for commercial construction. CAD & PDF files containing 2D MEP drawings were provided as input to begin the project. Navigating around challenges that included missing technicalities, complex 2D to 3D conversion, etc. a coordinated 3D MEP model was handed over to the client. The client leveraged the coordinated and clash-free MEP model to smoothen the MEP installation process.

2D to 3D MEP Conversion

Convert 2D MEP Drawings into 3D Drawings

PDF to CAD Conversion

BIM model-based shop drawings help fabricators build spatially accurate MEP components

Shop drawings for various MEP systems are crucial deliverables for fabricators to manufacture spatially accurate MEP equipment. Coordinated and clash-free 3D MEP models help contractors extract model-based shop drawings to reduce installation conflicts. BIM-driven MEP coordination reduces the numbers of RFIs and change orders leading to a better understanding of design and construction intent. This leads to greater building quality through efficient design workflows.

MEP coordinated drawings lead to 100% MEP component installation for airport facility, Muscat

TrueCADD built a clash-free 3D LOD 400 model supported by MEP coordination drawings for an airport project. With proactive clash identification, the client could save $7 million, achieve 100% MEP installation, reduce field conflicts, and change orders.

BIM Clash Detection

Clash Resoution

MEP Conflicts Checking

Material choice based on Revit libraries for MEP ensures better building quality

Material choices are important for sustainable designs and construction. Parametric Revit families ensure resolution and compatibility with multiple trades to enhance MEP component routing. With the shelf life of every MEP component extended and excessive run times reduced with accurate fabrication and installation, building contractors can reduce operating costs.

Fabricators can use standardized and custom Revit libraries, to better fabricate precision components. Sub-contractors use them to improve building insulation and reduce lag.

Improving building design and quality with MEP generative designing using automation

Generative designs enriched with parametric modeling tools can help design professionals spin up optimized model prototypes. AI or machine learning algorithms based on various design parameters can create multiple model versions for the best possible outcome. Designers and engineers are increasingly using the power of Revit Automation reinforced by Dynamo, APIs, and Plugins to create quick and error-free designs.

Agile workflows weed out repetitive tasks and enhance design efficiencies. Customized code scripting helps validate design integrity, automate manufacturing compliance, and manage BIM uniformity. Workflow automation, customized interfaces, automated conflict identification etc. help promote productivity and derive greater value for building contractors.

Conclusion

Sustainability is pivotal to building construction projects. Streamlining onsite MEP installation with “first time right” MEP design, fabrication, and reduced field conflicts helps stakeholders make informed decisions and save millions of dollars. The right Revit MEP BIM services partner can enhance building design through MEP coordination to project a clear picture of what needs to be built, manufactured, and constructed.

Precisely marked locations in MEP documentation exhibit reliable and consistent functions for onsite installation. Exceeding design expectations for seamless and high-quality construction helps set the baseline to meet client needs. If you’re looking for MEP BIM coordination services to foster accuracy and efficiency through every project stage, contact TrueCADD today!

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.

Learn more about our MEP coordination services

Learn more about our MEP coordination services