Cabinet makers rely on shop drawings to understand the design intent for each cabinet they produce. It’s the responsibility of CAD drafters to meticulously detail these drawings with relevant information. Discover the top four strategies for developing effective cabinet shop drawings and maintaining efficiency in manufacturing.

info@truecadd.com

Top 4 ways of creating effective cabinet shop drawings to drive manufacturing efficiencies

Table of Contents

Cabinet shop drawings bridge the gap between design intent and tangible cabinets, forming the backbone of the industry. When detailed with precision and clarity, cabinet drawings can streamline the manufacturing process reducing errors and optimizing resource utilization. They ensure that every piece fits perfectly and functions as intended and save manufacturing rework.

Precision cabinet drawings drive manufacturing efficiency by accurately communicating the exact design intend to the shop floor. They drive consistency across teams to communicate information and reduce misinterpretation. As a result, manufacturing becomes smooth and cost-effective.

Understanding the Basics of Cabinet Shop Drawings

Detailed cabinet shop drawings

Detailed cabinet shop drawings

Custom millwork, like in luxury or commercial kitchens, where every floor plan is unique, shop drawings take the highest importance for cabinet makers. They bridge the gap between designer’s and customer’s vision and craftsmen’s delivery.

Casework drawings developed from architectural floor plans are essentially the blueprints of cabinetry across the floor. They warehouse every single detail of the cabinets to reduce misinterpretations and every process follows precision and resources are optimized. Having cabinet shop drawings is like having the customer, the designer, and the manufacturer at one place.

For custom casework, the manufacturing processes are also highly tailored. At times, cabinet designers update casework shop drawings once civil construction is finished. Survey insights empower the designers to get exact as-built measurements. It will also ensure precision in operations like edge bending, thickness, instruction for installation etc.

How to Create Effective Cabinet Shop Drawings?

Creating effective shop drawings is the key to driving precision in cabinet manufacturing so that each cabinet fits perfectly into the provided spaces. Here are the top technical and non-technical ways for CAD drafting.

Technical Aspects for Creating Cabinet Shop Drawings

Drafting and Detailing

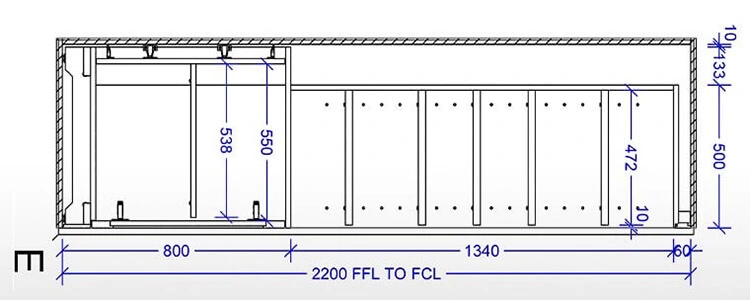

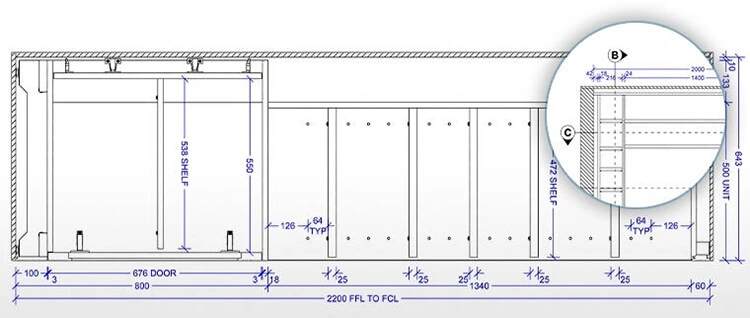

- When shop drawings are being prepared, detail all necessary information like sectional details, top views and side views, elevations, etc. separately. Such intrinsic details are usually not available on architectural floor plans. Shop drawing detailing helps the manufacturer to interpret inner details and requirements for cabinet construction. They also bring clarity for the approver and drawings get approved easily without much hassle.

Cabinet shop drawings

Cabinet shop drawings

- In kitchens, both residential and commercial, cabinetry covers appliances. It is kitchen cabinet drawings that are detailed with tolerances for spatial constraints during installation, maintenance and cleaning purposes.

Sectional drawings for cabinets

Sectional drawings for cabinets

- Following a uniform and standard dimensioning system for detailing drawings is another catch to avoiding simple mistakes. It establishes standardized way of communication and removes any discrepancies. Many a time, when parts of cabinet like doors, handles, etc. are manufactured separately and assembled, they may not fit perfectly. This is because they were all created with drawings following different dimensioning standards and manufacturing tolerances. Some CAD drafting companies use different measurements like metric or imperial measurements.

- Hardware like hinges, locks and other accessories are important parts of cabinet in creating the perfect finish. Cabinet shop drawings should communicate these details clearly to the shop floor. The critical aspect is communicating material thickness accurately so that the parts manufactured fit perfectly with each other exactly intended.

- In case of wooden cabinets, grain direction of wood can affect both aesthetics and the efforts put in for the manufacturing process. For example, cutting force reduces drastically when the angle between the job and the direction of cutter is low. Alternatively, if the grain direction is not considered during the design process, it can lead to a less than optimal final product.

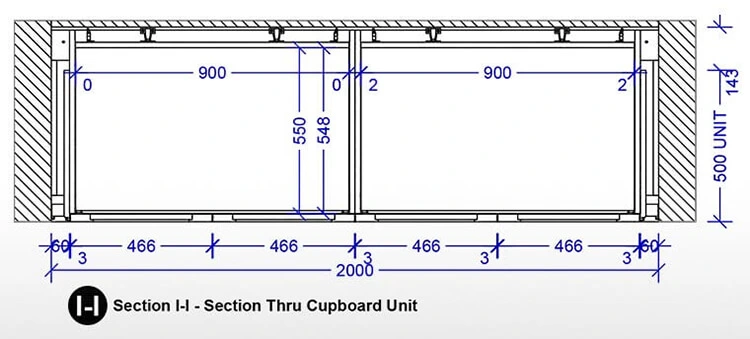

Cabinet assembly model

Cabinet assembly model

- Designer should take care that each part is labeled accurately with proper dimension and other information. If not done, it leads to confusion during manufacturing and assembly process.

- Many a time, when glue is used instead of dowel pins for joints, many dimensions get altered. Having a robust inter-team coordination is the biggest advantage to ensure that manufacturing, assembly and installation is done perfectly.

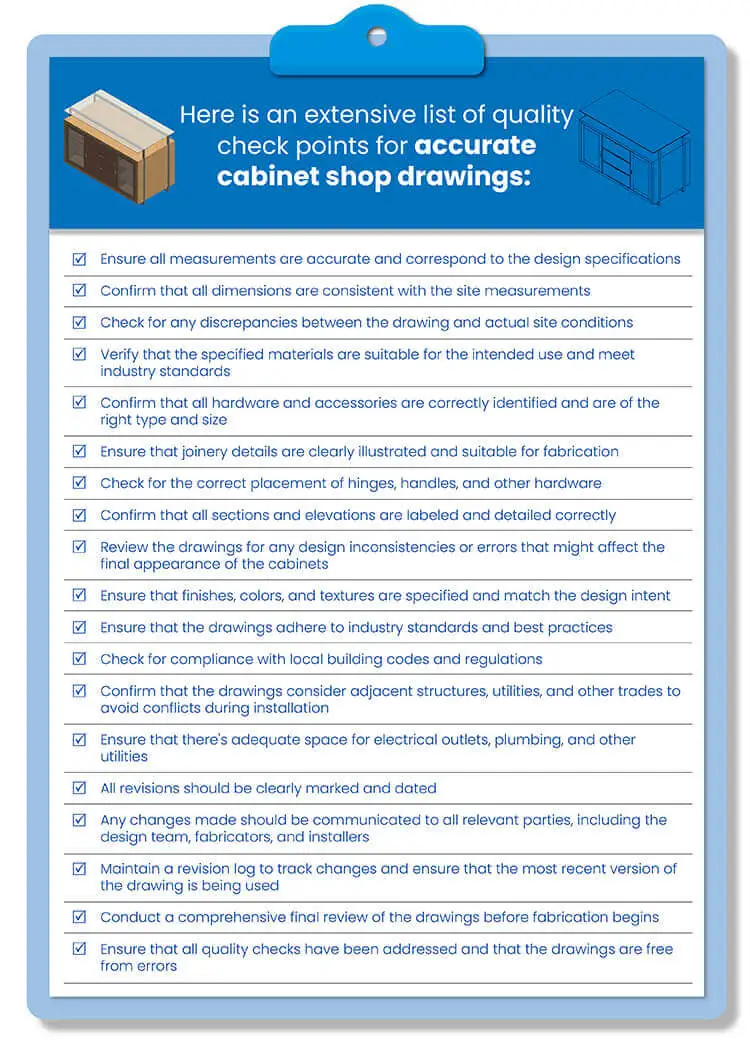

Quality Checks and Revisions

Since cabinet shop drawings are detailed plans offering a visual representation of the design, accuracy and quality are paramount. These drawings ensure successful construction and installation and hence need stringent quality check process in place.

Non-Technical Aspects for Creating Cabinet Shop Drawings

Use of Modern Design Software

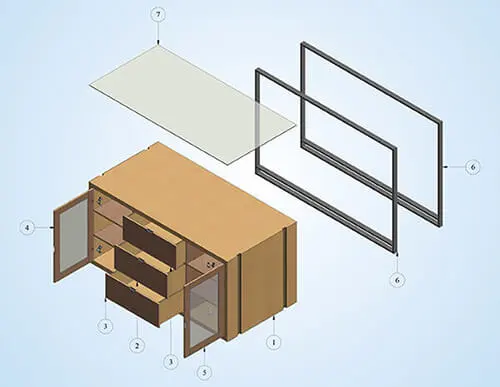

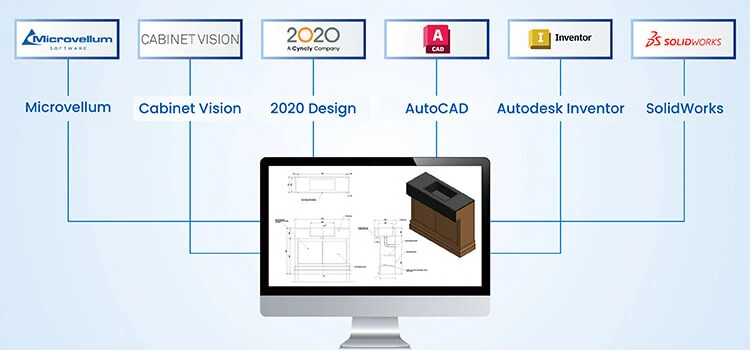

CAD platforms like Microvellum, Cabinet Vision and 2020 Design are some specialized software for cabinet design drafting. These software have a vast in-built library of materials used for cabinet, hardware, accessories etc. that can be used in design development.

Popular CAD software for cabinet drawings

Popular CAD software for cabinet drawings

The drag and drop option automatically fetches the physical properties of the material like grain direction, material thickness and other specifications. As against this, traditional CAD platforms like AutoCAD demands the designer to give manual inputs which can be erroneous.

Software like Microvellum, drives precision in creating manufacturing drawings. TrueCADD teams delivered accurate manufacturing drawings for a stainless steel manufacturer for a commercial kitchen furniture. The team reduced 50% TAT by using specialized software for creating countertop and cabinet shop drawings for the restaurant.

Regular Training and Skill Upgradation

With continuous market upgrades and changes, it is essential for the CAD drafters to stay updated and provide submittals in the contemporary format. Cabinet design engineers at TrueCADD equip themselves with the knowledge of the current market trends.

For instance, the CAD team at TrueCADD developed cabinet drawings for a luxury kitchen cabinet maker considering ADA applications. It ensured all drawings comply with the US disability act. Further, for another project, the team also uses Fair housing act design manual to design cabinets per the need of the region.

Besides these industry standards, another important aspect for the CAD drafting teams is to continuously upgrade their skills and knowledge. The intricacies of modern cabinet design demand a deep understanding of the latest software tools, techniques, and industry best practices. Regular training sessions, workshops, seminars and certifications have remained instrumental for TrueCADD team is well-versed with the newest software updates and features.

Staying attuned to industry trends through webinars, trade shows, and industry publications can provide insights into emerging design preferences and technological advancements. By prioritizing skill enhancement and staying abreast of the latest developments, CAD drafting teams can deliver quality work.

The Impact of Effective Shop Drawings on Cabinet Manufacturing

Improved Manufacturing Efficiency

Effective shop drawings provide a clear and detailed representation of the cabinet design, dimensions, and assembly instructions. When these drawings are precise and comprehensive, the manufacturing team can follow them without second-guessing or making assumptions. This streamlines the production process, minimizes errors, and ensures that each step is executed correctly the first time. As a result, the entire manufacturing process becomes more efficient, leading to faster production times and timely deliveries.

Reduced Material Wastage

One of the primary benefits of accurate shop drawings is the optimization of material usage. With a clear understanding of design intent, the manufacturers can plan processes to minimize waste. This not only conserves valuable resources but also translates to cost savings for the manufacturer. In an industry where material costs can be significant, reducing wastage can have a substantial impact on the revenues.

Enhanced Product Quality

Quality is paramount in cabinet manufacturing. Effective shop drawings ensure that every detail, from the type of joinery to placing hardware, is meticulously planned and documented. This means that the finished product closely adheres to the intended design and specifications. When the manufacturing team has detailed shop drawings, the chances of mistakes reduce drastically. This leads to cabinets that are not only aesthetically pleasing but also structurally sound and long-lasting.

Conclusion

Precision in cabinet shop drawings directly correlates with manufacturing efficiencies, ensuring that each cabinet piece is not only aesthetically pleasing but also structurally robust. The intricate details, accurate dimensions, and clear assembly instructions provided by top-notch shop drawings act as the backbone of the entire manufacturing process.

Cabinet manufacturers who aim to excel, do not care just about the designs; they care about translating that design into a tangible, high-quality product. Therefore, it’s imperative for manufacturers to prioritize these drawings and to invest the time and resources to perfect them. By doing so, they not only elevate the quality of their products but also position themselves at the forefront of an increasingly competitive industry.

Need precision in cabinet manufacturing?

Get our expert shop drawings

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.