Effective MEP clash detection in large-scale projects is important for MEP designers and engineers to mitigate costly rework, timeline delays, and security hazards during construction. Identifying and resolving MEP conflicts in the preconstruction stage leads to seamless construction, better coordination and lower costs.

info@truecadd.com

6 Effective Steps to MEP Clash Detection for Large-Scale Projects

Table of Contents

- Understanding the basics of MEP clash detection

- Role of MEP clash detection software in large-scale projects

- Step-by-step guide to performing effective MEP conflict resolution

- Challenges and solutions in BIM MEP clash detection

- Success stories on MEP BIM clash detection

- Benefits of effective MEP clash detection

- Choosing the right MEP clash detection software

- FAQs on MEP conflict resolution

- Future trends in BIM clash detection and MEP coordination

- Conclusion

MEP equipment is crucial for large-scale projects, as it delivers essential services, including heating, ventilation, power distribution, lighting, drainage and water supply. Precise design and integration with other trades like architecture and structure insure greater occupant comfort, improved functionality, and safety.

MEP interference detection flags spatial issues between various disciplines for MEP engineers, fabricators and the on-site team before work begins. This preemptive technique prevents rework, schedule overruns, and potential security issues. This leads to a seamless construction process and faster project delivery.

Unifying multiple models from various trades, including architecture, structure and MEP, in a single virtual 3D model allows a deep assessment of MEP equipment. This digital strategy improves coordination among disciplines for architects, structural engineers, MEP engineers, and project managers, which leads to fewer errors, improved collaboration, and cost-effective construction.

Understanding the basics of MEP clash detection

MEP clash detection includes the identification and resolution of interferences between MEP systems in a construction project. A coordinated and clash-free 3D model mitigates rework and ensures hassle-free installation.

Core principles of MEP clash detection

Clash detection highlights spatial conflicts between MEP equipment, such as a pipe intersecting a duct. Clash resolution in the preconstruction stage ensures smoother workflows, lowers material waste, improves MEP fabrication and leads to a winning project outcome.

Accurate, data-driven, and intelligent MEP integration based on BIM clash detection facilitates streamlined coordination between trades. Minimal ambiguities, improved communication between teams, and an optimized site layout expedite construction speed, lower material waste, and reduce project costs. All of these factors lead to greater efficiency for MEP engineers, fabricators, contractors and owners.

Types of MEP clashes

A coordinated 3D model from various trades can contain various clashes, including hard clashes, soft clashes, and workflow clashes. These three types of clashes are explained below:

- Hard clashes: Hard clashes are observed when building members and MEP equipment occupy the same physical space as a structural beam running through a duct. These clashes need to be identified and resolved early on, as they can affect construction and require quick design changes.

- Soft clashes: Soft clashes include clearance issues between MEP equipment for code regulations and maintenance access. For example, walls close to pipes can violate building regulations. Resolving soft clashes leads to greater maintainability and prevents costs and rework.

- Workflow clashes: Also called 4D clashes, these clashes include scheduling problems between MEP disciplines during actual construction. For example, ductwork installation before fire sprinkler lines can impede user access. Resolving these clashes early on prevents schedule overruns and improves construction sequencing.

Role of MEP clash detection software in large-scale projects

Advanced and feature-driven MEP interference detection tools offer automated clash detection, which provides customized tolerances and clash rules. They also support visual reporting with 3D views and in-depth reports and quick integration with multiple BIM tools. Robust capabilities like 4D clash detection and cloud-based collaboration are important for large-scale projects.

Let us take a quick look at MEP clash detection platforms:

- Autodesk Revit: offers basic clash detection features within the design space that are suitable for initial checks.

- Autodesk Navisworks: Includes powerful clash detection capabilities with clash reports, simulation and grouping.

- BIM360: A cloud-based platform that enables real-time collaboration and clash detection across teams with BIM360 coordinate and its integration with Navisworks.

Avoid costly construction errors with Navisworks clash detection.

Discover the advantages »Step-by-step guide to performing effective MEP conflict resolution

Before exploring the detailed MEP clash detection process, let’s outline the steps included. This approach provides a comprehensive and systematic interference detection process that leads to effective coordination and winning project results.

1. Preparing the MEP model

Ensure model accuracy, completeness and the use of consistent naming conventions.

- Collect and validate MEP design data: Start by collecting updated architectural, structural and MEP models from multiple participants. Ensure these 3D models are created in an IFC or. rvt format to achieve seamless software interoperability within Navisworks or other clash detection software. Validate each 3D model for accuracy, consistency and completeness while considering details like object properties and naming conventions. Also, confirm that every model is consistent with a unit of measurement to prevent ambiguities and ensure precise spatial analysis.

- Ensure MEP workflow optimization through standardized file formats: Standardized or interoperable IFC formats improve MEP workflows for architects, engineers and contractors. This reduces information loss and translational problems during export and import, ensuring data integrity for the entire clash detection process. Consistent file formats facilitate team collaboration and access to the most updated data. This seamless approach lowers manual information manipulation and improves overall efficiency.

2. Integrating MEP models into a common platform

Combine models from various trades, including architecture, structure and MEP, in a unified BIM environment.

- Discuss using BIM coordination platforms for MEP BIM integration: BIM coordination platforms like BIM360 and Autodesk Construction Cloud play an important role in MEP BIM integration. A unified environment for MEP engineers, contractors and fabricators to store, share and manage 3D BIM models enables real-time communication and collaboration between stakeholders. These platforms make workflows seamless, improve communication and enhance coordination, which leads to faster problem resolution.

- Tips for resolving compatibility issues between models: Compatibility problems between 3D models hinder interference detection. To navigate these obstacles, every participant needs to use a standardized format like IFC. Employ a model cleanup process to resolve inconsistencies and problems before importing them into interference detection software. Employ clear communication platforms and rules to foster the quick resolution of compatibility problems.

3. Running clash detection

Use clash detection tools within the software to highlight intersections between various building systems.

- How to identify clashes using MEP clash detection software: After importing and aligning 3D models, use the interference detection tool within software like Navisworks. Define tolerance and clash rules based on project needs and industry compliance. Run clash detection tests to highlight clashes. Inspect clash results in 3D views, isolate clashes and assess their severity.

- Best practices for generating comprehensive clash reports: Create comprehensive clash reports that include visualizations, including 3D views or screenshots of every clash. Categorize each clash based on severity, type and responsibility. Sort clashes based on their impact on safety and construction to make the complete process seamless for multiple teams. Resolution can also be achieved through the inclusion of element IDs and properties. Ensure reports are easily accessible and shareable with various stakeholders for effective coordination.

4. Analyzing and categorizing clashes

Review clash reports, highlight critical clashes, and assign teams for resolution.

- Grouping clashes based on priority (critical, medium, low): Sort detected clashes based on potential impact and severity. Critical clashes like hard clashes would require quick remediation. Medium clashes involve accessibility or code-related problems, while low-priority clashes may be minor, inducing minimal impact.

- Importance of collaboration in MEP conflict resolution: Collaboration between multiple project participants like architects, structural engineers, MEP contractors, and construction managers, makes the complete process seamless. Facilitate communication using shared platforms, clash reports and perpetual meetings. Encourage quick dialog and collaborative decision making to realize optimized solutions that satisfy every discipline.

5. Resolving clashes

Collaborate with project participants to redesign, relocate or modify elements to resolve clashes.

- Role of MEP coordination meetings in conflict resolution: MEP coordination meetings allow every stakeholder to discuss and provide feedback on clash reports, suggest solutions and resolve conflicts collaboratively. These meetings facilitate clear communication, and ensure every aspect is considered and that design revisions are accomplished.

- Updating the MEP design model based on clash resolutions: Once these clashes are resolved in coordination meetings, the MEP model is updated with the said revisions. This step ensures every trade is working with updated data, which prevents further conflicts and fosters a hassle-free construction process.

6. Validating the final model

Rerun interference detection tests to verify that all conflicts are resolved and document the modifications.

- Conduct a final review to ensure clash-free MEP systems: Resolve any remaining clashes by conducting an in-depth review of the coordinated 3D model. This includes a visual inspection of the model while rerunning interference detection tests. This strategy verifies that every conflict has been resolved. The final check ensures MEP systems are coordinated and clash-free before actual construction starts.

- How MEP design Integration enhances project delivery: Integrated MEP design driven by BIM and clash detection makes the project delivery seamless by enhancing coordination, mitigating errors, and lowering rework. This leads to accelerated construction, reduced costs and higher building quality, which meets functional needs and client expectations.

Implement these proven MEP conflict resolution steps with expert guidance.

Talk to our BIM specialists »Challenges and solutions in BIM MEP clash detection

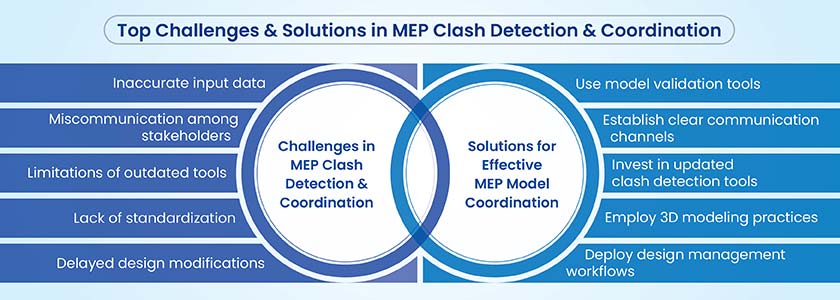

While MEP interference detection provides significant advantages, it also presents unique obstacles. From the management of complex models and advanced software to efficient collaboration, navigating these problems is critical for successful project handovers. Let’s explore a few challenges and their solutions.

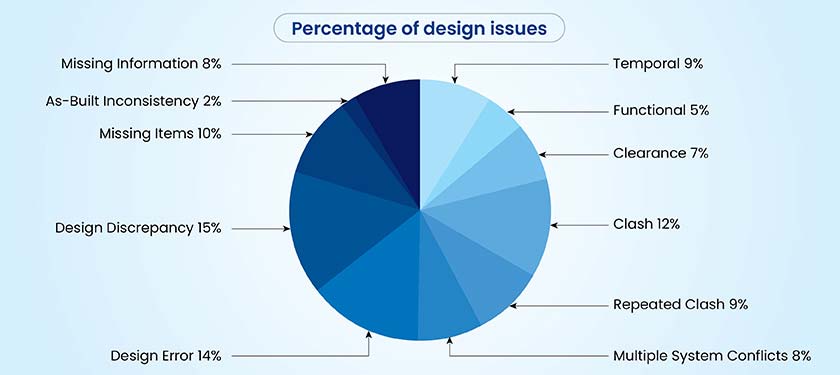

Top 5 challenges in MEP clash detection & coordination

MEP clash detection and coordination are key to ensure streamlined integration of building equipment. Challenges arise from tight spaces and complex geometries. Moreover, misalignment between trades leads to inconsistent 3D BIM models, causing delays and rework.

- Inaccurate input data: Errors in input data lead to incorrect interference detection, which causes conflicts that are not identified. Small inaccuracies in dimensions and specifications cause greater coordination problems.

- Miscommunication among stakeholders: When project participants are not able to communicate clearly, this results in misaligned needs and overlooked design components. Communication inconsistencies may cause critical modifications to go unchecked.

- Limitations of outdated tools: Legacy interference detection tools lack advanced features for managing complex geometries and flag potential clashes. This reduces the efficiency of coordination efforts and extends project schedules.

- Lack of standardization: Without a standardized process for data formats and 3D modeling practices, multiple teams struggle to align their work. A lack of standardization leads to the creation of inconsistent 3D models, provoking conflicts and delays.

- Delayed design modifications: Late design changes cause clashes that aren’t anticipated earlier. Changes or modifications that are not communicated effectively can impede coordination and cause project delays.

Top 5 solutions for effective MEP model coordination

Effective 3D MEP model coordination depends on advanced and integrated BIM and cloud-based tools for real-time collaboration. Standardized modeling, regular clash detection, and coordination meetings ensure alignment and issue identification across various trades.

- Use model validation tools and implement quality control checks: Validating the 3D model ensures MEP systems meet project needs and are error-free. Implementing thorough quality control checks throughout the entire design phase mitigates costly mistakes during on-site construction.

- Establish clear communication channels and collaborative platforms: Clear communication platforms ensure every stakeholder is aligned and issues are addressed quickly. Collaborative tools like BIM360 ensure real-time data sharing with updates that improve coordination across various disciplines.

- Invest in updated clash detection tools with automated clash grouping: Advanced interference detection is essential for identifying and managing complex clashes between MEP equipment. Automated clash grouping helps organize clashes into manageable sets, allowing teams to resolve multiple issues simultaneously.

- Employ 3D modeling practices like LOD, layer standards, and naming conventions: Using LOD standards ensures 3D MEP models are accurate and detailed, providing clarity across multiple trades. Consistence in layer standards and annotations helps simplify model navigation and integration, reducing miscommunication risks.

- Deploy strong design management workflows to re-run clash detection tests: Re-running clash detection tests for the entire design process helps with the identification and resolution of issues in the 3D model and ensures its accuracy and validity. This preemptive approach reduces the risk of costly modifications during actual construction.

Success stories on MEP BIM clash detection

The following real-world examples showcase the capabilities of MEP clash detection. From healthcare projects to commercial complexes, preemptive clash resolution reduces costs, saves time, and leads to improvements in project results.

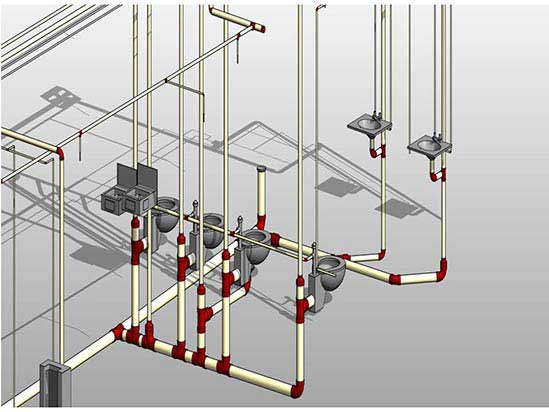

Coordinated and clash-free plumbing model at LOD 300 for a healthcare project in Australia

A design drafting company from Australia outsourced its MEP modeling needs to TrueCADD. 2D plumbing drawings were provided as input. Upon analyzing the input, the team had to navigate challenges, including MEP clash detection and resolution and coordinating architecture and structure with accurate clearances from electrical services. A coordinated and clash-free 3D model at LOD 300 was created using Revit with clash reports in Navisworks.

Upon handing over the deliverables to the client helped them:

- Leverage a single solution for 2D, 3D, Details, plumbing and insulation details.

- Visualize the drainage systems for underground and upper floors.

- Make informed decisions.

Underground Drainage

Underground Drainage

Upper Floor Drainage

Upper Floor Drainage

PDF to 3D MEP modeling with clash resolution for a commercial project in the USA

A construction company from the USA approached TrueCADD for a commercial complex project. PDF files of MEP 2D drawings were provided to the team to begin the project. Navigating multiple challenges like missing data within the input, conversion of PDF files into MEP models with international standards and coordinating MEP components led to the creation of a 3D BIM MEP model using Revit. MEP conflict resolution was performed and the files were shared with the client on the Revit CDE.

The final deliverables helped the client:

- Leverage improved insights

- Save time through clash elimination

- Make better decisions for MEP component installation

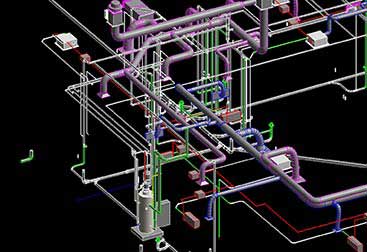

3D MEP Coordinated Model

3D MEP Coordinated Model

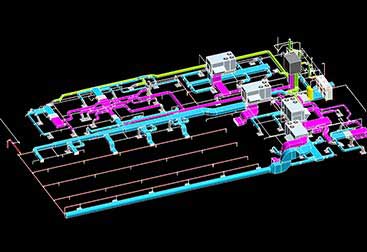

PDF to 3D MEP Modeling

PDF to 3D MEP Modeling

Benefits of effective MEP clash detection

Effective MEP clash detection leads to lower rework, mitigates project delays and enhances safety through the listing and resolution of inter-disciplinary conflicts. Here are some benefits of early clash detection.

- Streamlined MEP coordination: Remove conflicts and realize a hassle-free MEP installation based on interference detection and collaborative design.

- Enhanced project timelines and reduced costs: Identifying clashes in the preconstruction stage reduces reworks and prevents time overruns. This leads to precise schedules, lower material waste and greater project efficiency.

- Better communication through MEP BIM integration: Integrating interference detection with BIM improves communication by delivering a shared 3D MEP model for every stakeholder. This fosters a better view, expedites interference resolution and improves collaboration across trades.

- Improved design quality: Improve building performance, productivity and sustainability with enhanced MEP systems.

Experience the benefits of precise MEP clash detection in your projects.

Get started today »Choosing the right MEP clash detection software

Selecting the right MEP clash detection software requires a complete evaluation of parameters like budget, project needs, and tool capabilities. Prioritize features that deliver accurate interference detection, improve collaboration, and make workflows seamless.

- Compatibility with BIM tools: Make sure the selected software integrates with existing BIM tools, such as Revit. This helps with direct model import, higher data integrity and smoother workflows.

- User-friendly interface and reporting features: Select software with intuitive dashboards and advanced reporting features. This leads to quick navigation, faster clash analysis and communication clarity between users.

- Scalability for large projects: Select software or tools that can execute complex models driven by various MEP components and large datasets. Cloud-based tools offer greater scalability and performance for large-scale projects.

Future trends in BIM clash detection and MEP coordination

Looking ahead, let us explore future trends that will shape MEP clash detection and coordination.

- Emerging technologies in clash detection and resolution: Artificial intelligence (AI) and machine learning (ML) are being integrated into interference detection tools to automate clash detection, sort clashes based on severity and provide solutions to improve accuracy and efficiency.

- The growing role of automation and predictive analytics in BIM-based projects: Automation and predictive analytics are changing BIM-based projects through preemptive clash resolution, improving construction sequencing, and predicting potential issues, which leads to winning project outcomes.

FAQs on MEP conflict resolution

To help you understand MEP clash detection better, a list of FAQs has been compiled.

-

MEP clash detection identifies and resolves conflicts between MEP equipment in a construction project to mitigate rework and time overruns.

-

BIM fosters MEP interference resolution through 3D visual representation, which enables preconstruction clash detection and collaborative problem solving.

-

Yes, various MEP clash detection solutions can be integrated with multiple construction management tools.

-

Costs vary based on the selected software, project complexities and implementation requirements, but they include software licensing, software upgrades and training.

Conclusion

The future of MEP clash detection will be predictive and intelligent. AI will seamlessly combine with BIM to automatically resolve clashes before they manifest. Expect the creation of smart MEP models that will self-optimize based on real-time clash assessment. This will produce hyper-efficient, large-scale projects with greater safety and sustainable construction workflows.

This shift will allow MEP professionals to focus on optimization and innovation, while ensuring compliance with standards and sustainability goals.

Optimize your large-scale project with effective MEP clash detection.

Contact us today »Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.