2D and 3D CAD drafting are essential for manufacturers, architects, and contractors, directly impacting project execution and quality. When drawings lack accuracy, timely delivery, or high standards, project outcomes can suffer. Whether it is about manufacturing a quality product on time, or finishing a construction project within deadlines, CAD design and drafting services have a crucial role.

info@truecadd.com

Why Outsource 2D & 3D CAD Drafting Services

Table of Contents

Outsourcing CAD drafting to India is an ideal solution for large and medium-sized companies looking to free up core resources. Outsourcing CAD drafting saves time and costs, reduces infrastructure liability, and ensures high-quality deliverables through expert services.

What is 2D CAD Drafting?

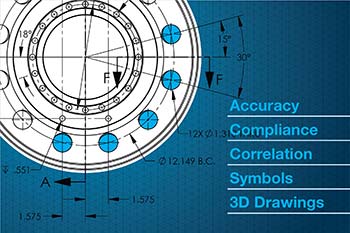

2D CAD drafting creates two-dimensional technical drawings using platforms like AutoCAD, SolidWorks, or Autodesk Inventor. Ideally, these 2D drawings consist of three different views – top view, side view, and front view – to convey the complete product design and geometry.

In each CAD draft, the product geometry is annotated with technical details like manufacturing footnotes, tolerances, manufacturing process, and machine allowances. CAD deliverables such as fabrication drawings, manufacturing drawings, shop drawings, sheet metal shop drawings, etc., primarily utilize 2D drafting.

What is 3D CAD Drafting?

3D CAD drafting, or 3D CAD modeling, involves creating three-dimensional models using a CAD environment. Various industry segments such as industrial products, furniture manufacturing, and building construction utilize 3D CAD modeling services.

What is the difference between 3D and 2D drafting?

| Aspect | 2D Drafting | 3D Drafting |

|---|---|---|

| Definition | 2D Drafting Uses lines to depict designs in two dimensions (height and width) | 3D Drafting Adds a third dimension (depth) to provide a more comprehensive representation of designs |

| Detail Level | 2D Drafting Limited to flat shapes, requiring multiple views to fully represent the design | 3D Drafting Can represent all shapes and products in a single file, providing a complete and clear visualization |

| Communication | 2D Drafting May require additional explanation, as it provides only a flat view | 3D Drafting Facilitates clear design communication across teams, especially for stakeholders from non-technical domains |

| Design Complexity | 2D Drafting Suitable for simpler designs or when less detail is needed | 3D Drafting Ideal for complex product designs, allowing for a detailed and realistic view of the design |

| File Creation | 2D Drafting Multiple views/files may be needed to show different perspectives of the design | 3D Drafting All design information can be included in a single file, simplifying the process and reducing file management |

What are the advantages of 2D or 3D CAD drafting services?

- Familiarity with 2D Drawings: More experts in the manufacturing industry are familiar with 2D drawings, which often suffice to communicate design intent.

- Clear Communication: 2D drawings efficiently convey design information between design engineers and shop floor engineers.

- Understanding Assemblies: Engineers can understand how each part fits in a multi component assembly through 2D drawings.

- Outsourcing Benefits: Outsourcing iterative drafting tasks frees up design engineers to focus on core activities.

- Handling Legacy Designs: 2D CAD conversion services help preserve and digitize legacy designs, enhancing the ability to add value or recreate parts.

- Attention to Detail: Requires significant time and attention to edit and refine drawing details, which is managed efficiently by CAD drafting companies.

Discover how our expert 2D & 3D CAD drafting can streamline your production process.

Get a free consultation now! »Why outsource CAD drafting services to India?

India has established itself as a leading outsourcing hub for numerous industries, particularly in engineering CAD drafting. This process, which requires detailed attention and close collaboration with design engineers and other stakeholders, can be both time-consuming and resource-intensive. Some benefits of hiring CAD outsourcing companies in India include:

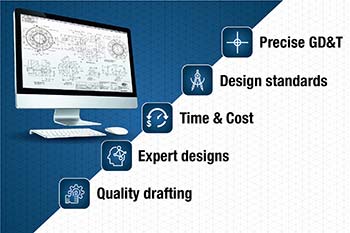

A team of expert CAD drafters

Achieving excellence in CAD drafting goes beyond just accuracy and adhering to design standards. It demands a profound understanding of precise geometry, appropriate use of drawing symbols, and effective communication of manufacturing processes.

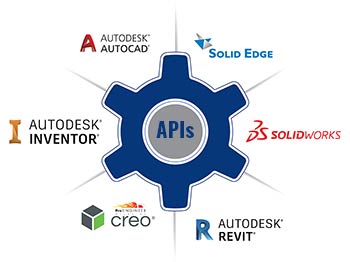

Offshore CAD drafting teams meticulously mark slopes, depths, arc curvatures, datum symbols, orientations, and other features in manufacturing drawings or shop drawings. They utilize various parametric CAD platforms like Autodesk AutoCAD, Autodesk Inventor, SolidWorks, Creo, etc., to share accurate design intent through 2D and 3D drawings.

Enhanced quality and faster turnaround time

The quality of drawings and the turnaround time are crucial aspects of CAD drafting projects. These factors heavily influence every step of production and project execution. Lack of quality at any point results in wasted time, rework, and delays. When an outsourcing company handles a CAD drafting project, they assign dedicated teams and help overcome these challenges.

For example, offshore CAD teams work 24×7 in shifts, leveraging the time zone difference. If you share inputs at the end of your day, the offshore teams can pick up the work because it’s the beginning of their workday. They update you on work completion at the end of their day, so your work is ready on the table when you begin work the next day.

Furthermore, offshore CAD teams have years of experience and expertise. They help identify design loopholes and highlight them for elimination. They are also capable of developing design drawings that comply with internationally accepted standards such as IS, ASME, or ANSI.

Improved productivity by leveraging 3rd party software and APIs

While CAD platforms offer a range of functionalities, they often benefit from external applications and APIs that streamline and optimize the design process

For example, adding repetitive features such as holes in sheet metal modeling can be time-consuming. Using 3rd party software like DriveWorks or running a CAD macro can automate the command and generate the pattern quickly. Platforms like Bluebeam also allow markups in digital drawings, which are highly useful for cost estimation and quantity takeoffs.

Quick ramp-up and ramp-down of resources

The manufacturing industry experiences market fluctuations throughout the year. This means that the workload for design engineers increases during peak times and decreases at other times. However, hiring and firing resources based on varying demands isn’t a sustainable option.

Having an offshore CAD team on board allows you to tackle this situation efficiently. The outsourcing model empowers you to bring in more resources when the workload increases. They can work during busy periods and help meet timelines. When the workload reduces, the extra resources can be benched, and you don’t have to worry about costs and legalities.

Boost your design team’s productivity with customized CAD solutions.

Contact us for CAD drafting solutions »How much does CAD drafting cost?

The cost of CAD drafting depends on several factors, such as expertise, level of detailing required, and the type of drawings. However, one can expect the cost to range between $120 and $150 per hour. Some CAD companies also charge CAD drafting fees based on engagement models like staff hours or the number of drawing sheets.

When searching for CAD drafting services in India, it is important to consider the following factors before finalizing the hourly rate for drafting services:

- Expertise

- Education and experience

- Number of iterations accommodated

- Project length

- Scope of work

- Portfolio

- Customer reviews

Conclusion

Collaborating with a CAD drafting outsourcing company enhances the overall efficiency of your design team and expedites the project lifecycle. Manufacturers can dedicate their in-house design engineers to design optimization and innovation.

An overseas CAD company has a dedicated taskforce for close coordination with your teams at various stages of design development. At True CADD, we offer different engagement models for collaboration based on your project length and scope of work. Email us, and we’ll respond within 24 hours to address any queries you have regarding a project or idea.

Start saving time and cutting costs with our expert CAD drafting services.

Get in touch now! »Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.