3D CAD modeling stands as a game-changer, melding precision with efficiency to redefine furniture manufacturing norms. Parametric furniture CAD models give a winning edge to manufacturers by eliminating design errors with unparalleled accuracy and cost-effective approach.

info@truecadd.com

How does 3D CAD modeling help furniture manufacturers?

Table of Contents

- Furniture modeling challenges without 3D CAD

- Benefits of 3D CAD for furniture design modeling

- High precision and intricate detailing

- Decreased cost of operations

- Speed in design process

- Realistic 3D visualizations for sales and marketing

- Easy and fast customization with design automation platforms

- Creative freedom in design exploration

- Reduction in errors, material waste

- Effortless scaling of designs

- Seamless collaboration with other teams

New-age furniture is more than just comfort and storage. Customers today want customized furniture pieces with remarkable efficiency. Though the furniture manufacturing industry is adapting to such changing preferences and offers functional and aesthetically appealing furniture, it suffers on turnaround time and quality. The cost is going skyward.

From reducing errors and costs to enabling a sustainable manufacturing approach, furniture needs streamlined design process. 3D CAD Modeling for furniture manufacturers has offered faster design development with quality and accelerated design-to-manufacturing cycles.

3D CAD modeling saves time by allowing you to make changes in the existing design without having to build it from scratch, along with better design communication and improved quality.

Furniture modeling challenges without 3D CAD

Contemporary furniture designing and manufacturing is dependent on the abilities of the designer to combine function with fashion. And as customer needs increase, challenges in manufacturing such furniture increase further.

Benefits of 3D CAD for furniture design modeling

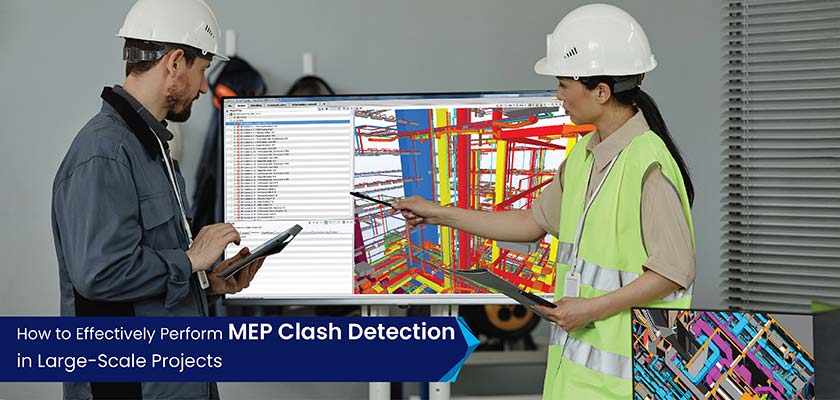

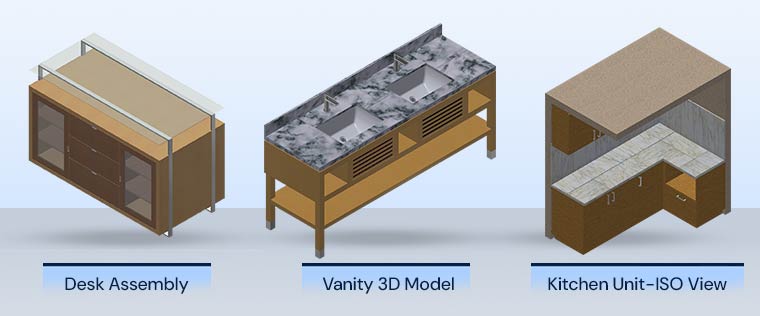

The furniture industry has embraced 3D CAD modeling as one of the biggest technological innovations. Significant advancements are seen with the introduction of 3D modeling and photorealistic 3D rendering. The capacity of designers to make life-like models that potential buyers can envision inside their facility has permitted them to draw in more customers.

High precision and intricate detailing

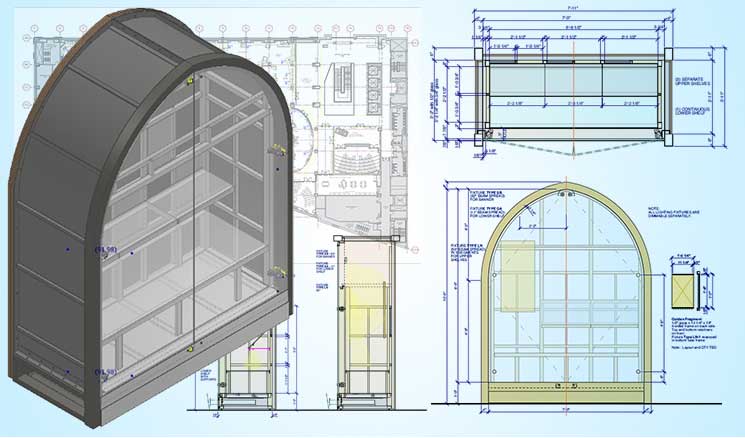

CAD software allows for exact measurements and fine detailing, ensuring every aspect of the furniture design is accurate to the millimeter. This precision is crucial for complex joinery and intricate designs, ensuring that all parts fit together perfectly during manufacturing.

Decreased cost of operations

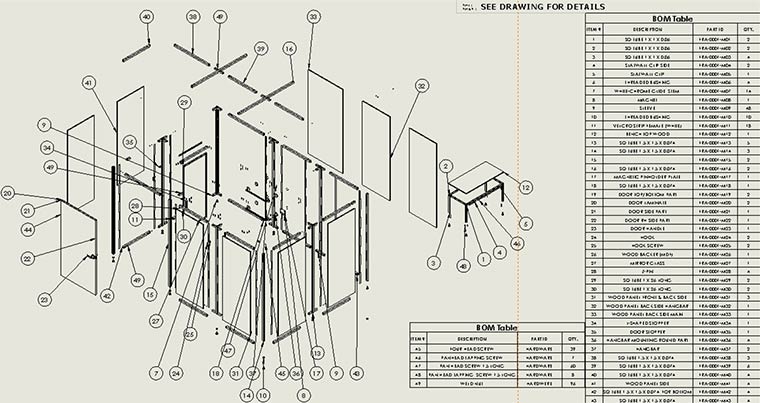

This concept aligns with the theory of Postponement, where again, parametric modeling emerges a true hero. It can help you conveniently design and manufacture semi-final assemblies from the Bills of materials (BOM). These semi-final products can wait until the final demand arrives wherein they can be quickly assembled and dispatched. A modular design approach like this helps you create multiple final configurations with same semi-final parts and saves cost by achieving economies of scale in production.

Rather than mass-producing a particular design in one color or fabric, you can first understand the market demand and create products that get the most orders.

Furniture manufacturer saves 60% design costs with 3D CAD drafting

A furniture manufacturer was facing difficulty in understanding the original design intent and accommodating changes within. They outsourced their design detailing to TrueCADD and the decision resulted in:

- 45% reduction in transportation costs due to knockdown design approach

- 60% reduction in design costs

- 30% inventory benefits with a modular design approach

- 70% reduction in overall design cycle due to offshore design development

Speed in design process

With CAD, changes that would have taken hours by hand can be done in minutes. Automated features like copying, mirroring, and repeating patterns streamline the design process, allowing designers to explore multiple variations quickly and efficiently.

Realistic 3D visualizations for sales and marketing

CAD provides the ability to create detailed 3D models, offering a realistic view of how the furniture will look in a real-world setting. This aids in better decision-making regarding materials, colors, and overall aesthetics, reducing the likelihood of costly changes later in the production process.

High-quality 3D renderings and animations created from CAD models can be powerful marketing tools. They allow potential customers to visualize the furniture in a realistic setting, making it easier for them to make purchasing decisions.

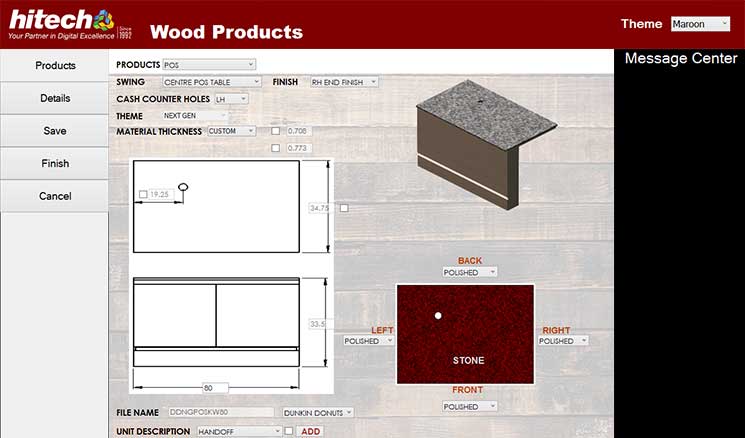

Easy and fast customization with design automation platforms

CAD software enables designers to easily modify designs to suit specific client needs. Whether it is adjusting dimensions, adding unique features, or experimenting with different materials, these customizations can be made quickly without having to start from scratch.

3D CAD models make design approvals faster and can introduce manufacturing early in the engineering cycle. By building a precise 3D CAD model of furniture product; this model with strategic points will help create DXF files for manufacturing.

TrueCADD team delivers 70 times faster design cycle for furniture manufacturer

A furniture manufacturing client needed to reduce engineering lead time and improve accuracy in customization. Based on the custom design specifications, our SolidWorks engineers developed 3D CAD models which were later customized in DriveWorks.

The results achieved:

- Reduction in lead time from 4-5 days to one day

- 70 times faster design cycle

- Enhanced quality with direct DXF files

- Significant reduction in material scrap during machining

Creative freedom in design exploration

With CAD, designers can experiment with more innovative and complex designs without the constraints of manual drafting. This freedom allows for the exploration of new forms, structures, and functionalities, pushing the boundaries of traditional furniture design.

Reduction in errors, material waste

The accuracy of CAD modeling significantly reduces the chances of errors that can occur in manual drafting. This precision leads to a more efficient use of materials and a reduction in waste, as the dimensions and specifications are clear and accurate. Often, a CAD service provider offers minimal to nil errors because of their teams experts in their respective domains.

Furniture manufacturer reduces errors with 3D CAD modeling

A US-based client from the furniture design and manufacturing space, faced the challenges of slow-paced design cycles. Due to iterative designs and improper communication between the designer, manufacturer, and general contractors the engineering lead time was increasing.

TrueCADD engineers developed comprehensive manufacturing drawings, accurate assembly and installation guides to eliminate rework which resulted in:

- Significant reduction in turnaround times

- Higher quality output

- Synchronized communication between design and manufacturing teams

Effortless scaling of designs

CAD software allows for easy scaling of designs, maintaining the accuracy and proportions of the furniture piece. This is particularly useful when creating a range of products in different sizes or when adjusting a design to fit a specific space.

Seamless collaboration with other teams

CAD models can be directly used in CNC machines and other manufacturing processes, reducing the time and potential for errors in translating a design into a physical product. This integration streamlines the production process, making it faster and more cost-effective.

Digital CAD models can be shared easily with clients, manufacturers, and other stakeholders, regardless of their location. This facilitates clearer communication, as everyone can view the same model and provide feedback, leading to a more collaborative and efficient design process.

Conclusion

As a furniture manufacturer, you would want to offer unparalleled precision, efficiency, and creativity to your customers. While putting resources into expanding your manufacturing capacities is necessary, quality furniture models and design development are a central point that represents your furniture manufacturing proficiency.

3D CAD modeling for furniture manufacturers helps customers visualize products before manufacturing to make informed decisions. By embracing 3D CAD modeling, furniture manufacturers can not only enhance product quality and design innovation but also significantly reduce costs and time-to-market.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.