Furniture manufacturing industry offers numerous design options for a single product to address personalization needs. It has led to increased turnaround time and delays. DriveWorks design automation leverages logical rules to configure products faster and avoid process delays.

info@truecadd.com

How DriveWorks Helps You to Reduce Lead Time in Manufacturing

For manufacturers operating in today’s saturated markets, reducing the lead times and scaling up bespoke product deliveries is critical for sustainable business growth. To drive sales, they must be able to design and manufacture custom products faster, sell smoother, and ensure on-time delivery.

Slow approval processes delay manufacturing and create longer lead-time, directly impacting customer satisfaction. Customers may look for alternatives in such cases, adversely affecting sales. Implementing DriveWorks automates the repetitive modeling process and speeds up approvals, reducing time to market.

Factors affecting lead times in custom product manufacturing

- Specific customer demands: A customer demanding specific product features and dimensions will need designer’s and shop engineer’s approvals. Frequent changes in order specifications by customer results in complexities and delays.

- Tooling capabilities: Each time there is a design customization, machine setup needs to change, which again is a time consuming process.

- Supply chain: A product may require multiple parts coming in from different suppliers and incase of ETO products- the time between order receipt and delivery is too short. Failure to deliver the parts on time can disrupt the process schedules leaving manufacturers in lurch.

- Communication: Communication gaps, siloed systems or processes, and discrepancies between sales, design and manufacturing divisions disrupt product cycles and add to engineering lead times.

Automated tools and 3D product configurators through design automation platforms, help sales teams sell well and eliminate repetitive design tasks to accelerate design cycles.

How DriveWorks eliminates bottlenecks and reduces lead time

1. Automating the design modeling and drafting process

Manufacturers know that in order to beat competition, they must be quick to bring the product to market. However, for manufacturers who develop products which look the same but are customized for specific customer requirements, multiple design iterations and troubleshooting can eat into a project’s time and expense.

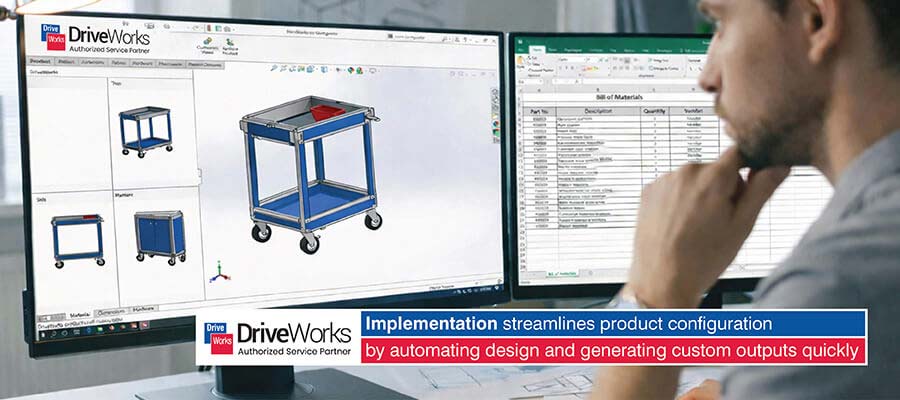

DriveWorks offers design automation to help manufacturers work smartly by automating repetitive design tasks.

The logical-rules for design automation in DriveWorks ensure:

- Elimination of errors and expensive, time-consuming design changes.

- Empowered sales team through an interactive design platform with 3D visualization.

- Automation of repetitive modeling as per specifications and removal of approval and errors.

- Removal of unnecessary delays and reworks due to ECOs from shop floor.

These factors collectively eliminate time consuming processes at any stage during designing and drafting.

Furniture manufacturer in USA gets 70 times faster design cycles with DriveWorks

Design automation engineers at TrueCADD have reduced design lead time for a metal and wooden furniture manufacturer in the USA to deliver 70 times faster design cycle. Automation specialists developed logical rules to eliminate non-productive and repetitive tasks using rules-based configuration for furniture products.

2. Automating sales quotations

Offering customized products is a great way to win more customers and generate more sales. However, to manage greater volumes of new business and to simplify the buying process also requires automated sales configurator.

DriveWorks reduces errors and saves time with automated quotations and cover letters. It allows dealing with customer queries faster, resulting in more orders, reduced operational overheads, and better customer service by integrating with ERP systems.

The integration of DriveWorks with SolidWorks and other ERP, CRM, SCM, etc. offers:

- Quick sales proposals to help win more business and drive sales revenues.

- Showcase entire product range, catalogue and instant quotes, delivery dates etc. at the time of order placement.

- Reduced costs due to mistakes and incomplete proposals.

- Eliminated need for web programming skills or consultants to build and maintain an online sales configurator.

These aspects of DriveWorks essentially guide the customer during the sales process offering enhanced experience. Further, when connected, the integration can give insights for the opportunities to cross-sell and up-sell products.

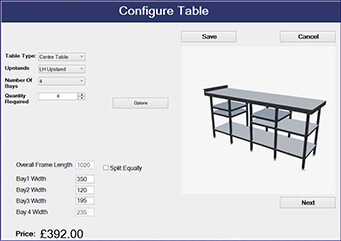

DriveWorks helps speed up quotes with 100% accuracy for table manufacturer

A UK based stainless steel retail furniture manufacturer enhanced customer satisfaction by generating custom quotes using DriveWorks. DriveWorks engineers at TrueCADD partnered with the firm to setup a custom furniture configurator that generated 100% accurate sales quotes along with sales documents to respond to customers on time.

3. Automating inventory management

Efficient management of inventory is a crucial step in managing a smooth production flow. Unavailability of certain items can put the whole production on hold. Failure to replenish raw materials increases the lead time. Being able to accurately forecast growth or demand for your products is only half job done.

Inability of suppliers to deliver materials on time can become a manufacturing challenge. At the same time, holding too much inventory is expensive and may lead to wastage.

DriveWorks design automation platform offers integration with ERP automation to ensure all resources are put to optimum use. It helps to automate the stock-taking process, optimize supply chain management, and balance working capital by acting as a bridge between ERP, engineering, and manufacturing.

By connecting a design automation platform with ERP you get to:

- Reduce order processing time and optimizes picking and orders shipping, notifying manufacturers on inventory refills.

- Automate warehouse processes, optimizes material flow, and helps to maintain accurate stock levels.

- Boost sales by keeping a track of sales using features like raw material management, bar-cording, inventory control, and more.

- Clear the beltway faster for improved order processing.

4. Automating the manufacturing data generation

Manual collection and formalization of plant and process data is the most time consuming and prone to errors. Most of the required data can be found in engineering data and data generated by other integrated systems like ERP, MES, SCM and more.

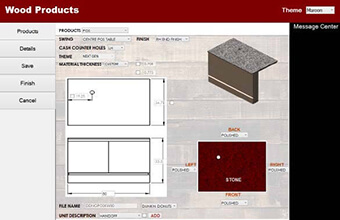

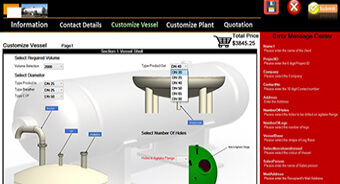

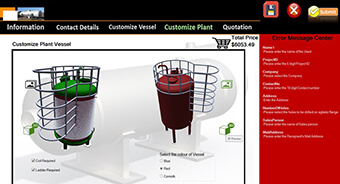

3D product configurator made with DriveWorks gives you the toolset to automatically and accurately create manufacturing drawings and other supporting documentation. It offers automation of manufacturing data, emails, sales quotes and more based on the existing and captured data library.

Advantages of design automation for manufacturers:

- Helps to automatically create custom manufacturing drawings, BOMs, and more without errors using annotation text, annotation positions, layers, break lines, etc.

- Helps to put to use static tabular engineering data within the rules and forms by centralizing and maintaining data and also ensuring that the data is error-free and updated.

- Improves productivity of multiple teams.

Tank manufacturer reduces ECOs by 99.9% to save time with DriveWorks configurator

A USA based pressure vessel manufacturer approached TrueCADD to automate manufacturing drawings generation which was time taking, as all vessels had to abide by strict ASME Standards for the highest safety. TrueCADD’s DriveWorks specialists captured design knowledge from Master CAD model and replicated it to customize drawings as per predefined rules based on design standards. This accelerated manufacturing drawing generation with BoMs and reduced ECOs from shop floor.

Conclusion

Shorter lead times help to achieve reduced carry costs, streamlined operations, and improved productivity. Lead times vary from industry to industry but they should be consistent and short to drive success in a business. An authorized partner can help you implement DriveWorks from start to finish as per your business needs.

If you are looking for implementing design automation, and accelerate lead time, reach out to us. We, at TrueCADD, are the authorized service partners for DriveWorks. Our automation specialists will not only help you implement but also enable informed decision making for further scope in future.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.