In the construction industry, shop drawings refer to accurate, in-depth, and scaled diagrams generated by project stakeholders for the respective parts of their work. They provide detailed information about dimensions, materials, techniques, and whatever is necessary for the fabrication, installation, and assembly of architectural, structural, and MEP components.

info@truecadd.com

How Shop Drawings Reduce Risks in Construction Projects Liabilities

Construction shop drawings are important for project coordination and execution, in accordance with the intent of the architect and engineer. They provide precise instructions for all perceptible structures, including steel beams, architectural elements, HVAC systems, electrical wiring and plumbing equipment.

Table of Contents

- Challenges faced without accurate shop drawings in construction

- Shop Drawings: A Detailed Insight

- Role of Shop Drawings in Ensuring Design Intent

- Importance of Accuracy in Shop Drawings

- Top 5 steps to create accurate shop drawings

- Shop Drawing Success Stories

- Conclusion

- FAQs Related to Shop Drawings

The inability to create and use accurate and complete construction shop drawings can lead to a lack of clarity about project scope, execution errors, costly rework, greater labor costs, material waste, onsite conflicts, and legal consequences. Accurate shop drawings enable AEC stakeholders to improve construction project risk management.

Challenges faced without accurate shop drawings in construction

- Project delays: Ambiguous directions lead to delays in construction projects, fabrication, installation, and assembly that disrupt project timelines.

- Miscommunication: Incorrect or unreliable information leads to confusion between various team members, which results in errors and costly rework.

- Budget Overruns: Rework and project delays create cost overruns based on extended time, labor, material wastage, and potential penalties.

- Quality issues: Absence of accurate details jeopardizes work quality, leading to below-average construction and safety issues.

- Coordination problems: Fragmented MEP shop drawings impede coordination between multiple disciplines or trades and fuel conflicts during on-site construction.

- Legal issues: Inconsistencies within actual work and submittal of incomplete shop drawings lead to legal problems between project teams.

- Client dissatisfaction: Construction projects plagued by inaccuracies, delays, reworks, clashes, and quality issues lead to client dissatisfaction that can damage contractor reputation and affect future businesses.

Shop Drawings: A Detailed Insight

Types of Shop Drawings (Architectural, Structural, MEP, etc.)

Construction shop drawings are precise, detailed, and scaled to deliver specialized information for multiple elements. They include architectural, structural, mechanical, electrical, and plumbing plans for precise construction and ensure that building elements comply with design, codes, and safety protocols.

Architectural Shop Drawings

Architectural shop drawings are meticulous plans or blueprints created by architects to offer accurate details of construction elements, including doors, windows, and finishes. These drawings serve as guides for craftsmen and builders for the accurate and complete realization of architectural design and for achieving effective construction in synergy with the architect’s vision.

Structural Shop Drawings

Structural shop drawings are explicit blueprints that illustrate important parts of the building framework or structure. Generated by structural engineers, these shop drawings provide precise plans of concrete elements, such as beams, columns, and connections. These drawings serve as an essential guide to ensure accurate construction based on component load bearing to guarantee structural integrity.

MEP Shop Drawings

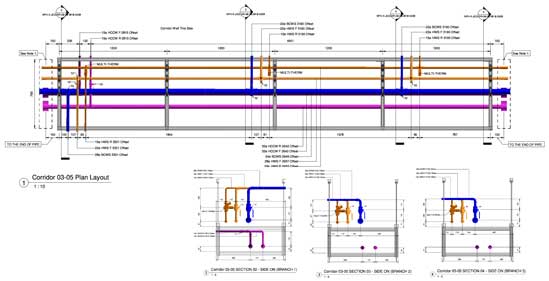

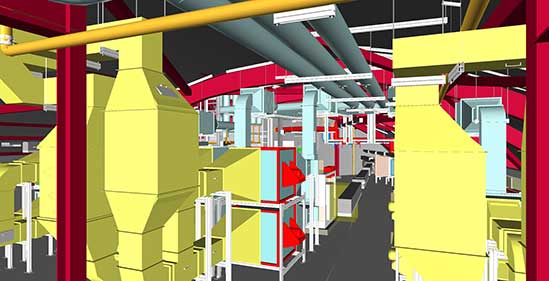

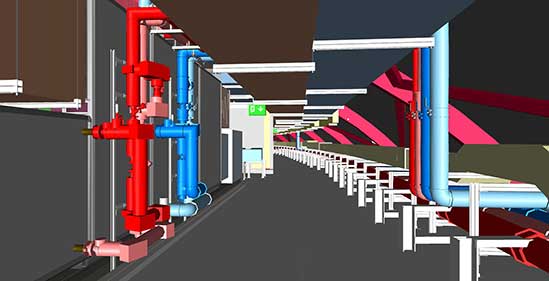

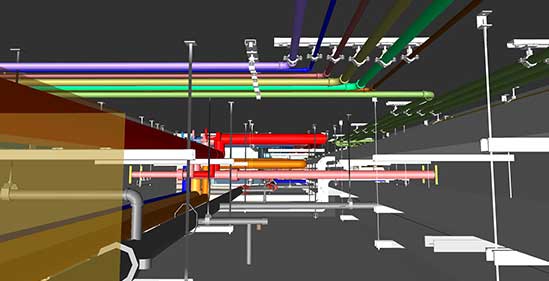

MEP shop drawings lay a greater focus on mechanical, electrical, and plumbing systems. Detailed plans provide intricate information on HVAC systems, electrical wirings and connections, and plumbing systems.

Built by MEP engineers, these drawings provide specifications for HVAC components, electrical layouts, and plumbing equipment. These play a vital role in supporting seamless coordination between various building systems and offer system specifications, including ductwork, pipes, wiring, and other equipment.

MEP shop drawings also serve as a roadmap to guide the construction process for MEP elements to function in harmony for various projects, including residential, commercial and other project types.

Role of Shop Drawings in Ensuring Design Intent

Shop drawings play an important role in realising design intent within construction projects. Serving as detailed and customized plans generated by contractors, manufacturers, and fabricators, these drawings bridge the gap between practical implementation and conceptual design, allowing designers and clients to visualize the finalized product. Meticulous detailing of dimensions, construction techniques, and materials, these construction shop drawings assure that the finished product aligns with the intended design to ensure precision, functionality, and project wins.

Importance of Accuracy in Shop Drawings

Accurate information carried by shop drawings streamlines communication between various teams and stakeholders to achieve a unified understanding of design. Furthermore, accuracy and precision ensure design integrity, increasing building efficiency and keeping construction costs under control.

Reducing Risks through Shop Drawings

Ensuring Compliance with Building Codes and Regulations

Shop drawings play an important role in reducing risks within construction projects through compliance with regulations and building codes. These elaborate blueprints produced by contractors show accurate material specifications and installation techniques. Thorough reviews of shop drawings support architects and engineers in confirming that the proposed plans align with local regulations and safety standards.

Thorough assessment supports the identification of potential problems before actual construction begins and helps mitigate expensive errors, ensuring the project conforms to legal rules and regulations. Furthermore, the use of precise shop drawings lowers the risk of insecure and inefficient construction.

Identifying and Resolving Design Conflicts and Issues

Construction shop drawings minimize risks during construction projects through the identification and resolution of design conflicts and issues. Accurate, detailed and updated shop drawings serve as a bridge between architectural plans and on-site realization of design intent.

Exhaustive audits of shop drawings mitigate clashes and ambiguities in the preconstruction stage by rectifying them before actual construction begins. This preemptive method prevents costly problems and ensures swift construction. Thus, shop drawings are vital deliverables that improve construction project risk management.

Minimizing Miscommunication among Project Stakeholders

In construction projects, risk reduction depends to a great extent on accurate shop drawings. They address miscommunication issues between project teams and stakeholders.

Enhancing Collaboration between Contractors, Architects, and Engineers

Shop drawings promote project-wide collaboration between architects, contractors and engineers. Better collaborative workflows improve understanding of design intent and resolve potential issues faster. This ensures project errors are minimized, leading to improved construction project management and minimal setbacks or issues.

Liabilities in Construction Projects

Common Liabilities Faced by Contractors and Project Owners

Ignoring building codes, standards and regulations poses a serious threat for construction projects, contractors and project owners. Common liabilities include preventing building defects, workplace accidents and project delays. Contractors may be held responsible for below-average work or schedule overruns leading to legal issues.

Project owners face liability implications related to quality, adherence to regulations and build quality. Rigorous contracts need to be set in place to address these liabilities based on risk assessments and strong safety protocols to safeguard every party involved in the construction process.

Legal Implications of Design Errors and Omissions

Construction design errors and omissions produce significant legal issues that lead to cost overruns, delays, and structural problems that expose architects, contractors, and engineers to legal liabilities. Contractors may face contract breaches based on flawed designs, while architects and engineers could be held accountable for professional failures.

Legal problems arising from errors emphasize the need to generate comprehensive documentation that includes construction shop drawings, extensive quality control, and collaboration to resolve liabilities. Proactive risk management and adherence to global construction standards are crucial to avert legal issues and uphold project performance and reliability.

Financial Consequences of Construction Liabilities

Construction non-compliance has significant financial implications. Architects, contractors, and owners face a great number of cost-based delays, defects, and safety breaches. Fines, premiums, and legal battles increase the financial strain.

Furthermore, resolving errors requires additional expenses that could significantly impact budgets. Delays in projects can lead to hefty penalties. These consequences emphasize the need for extensive QC, regulations compliance, and complete risk management in the construction industry.

The Role of Shop Drawings in Reducing Liabilities

How Accurate Shop Drawings Prevent Design Errors

Construction shop drawings help manage liabilities in construction projects through preemptive error detection and resolution. Depictions of specifications and construction details and reviews ensure that the intended vision connects with the proposed design.

Shop Drawings as Documentation for Compliance

Ensuring compliance to mitigate liabilities is achieved through the use of accurate, complete, and data-rich shop drawings. These drawings deliver a sharp representation of project execution through the illustration of building materials, architectural, structural, and MEP dimensions, and their installation methods.

These detailed shop drawings serve as benchmarks to achieve compliance with architectural blueprints and industry norms. Thorough review and approval of these drawings lowers the risk of errors, serves as a complete compliance record, safeguards liabilities, and adheres to specifications.

Shop Drawings in Dispute Resolution and Legal Cases

Dispute resolution and legal cases are significantly lowered through the use of shop drawings. With every detail illustrated within shop drawings, contractors can leverage clear project documentation with accurate specifications and clear intentions.

In the case of a dispute or a legal issue, construction shop drawings are indispensable proof for resolving conflicts based on visual representations of the proposed plans. These drawings improve transparency, diminish legal liabilities, and lead to fair project resolution to protect all the parties involved in the project.

Top 5 steps to create accurate shop drawings

Creating accurate, information-rich, and detailed shop drawing sets is crucial for construction projects. Here are the top 5 steps to achieve the creation of excellent shop drawings.

Understand Project Details

A comprehensive understanding of architectural and engineering plans is important for creating shop drawings. Collaborate and communicate with architects and engineers to understand project requirements and ensure an accurate representation of the plans.

Measure

Produce precise measurements and on-site inspections to collate accurate dimensions and specifications. Paying close attention to detail mitigates errors in the final drawings.

Communicate

Build open and effective communication in the construction industry with various teams and stakeholders, such as architects, engineers, and contractors. Addressing queries quickly and making sure everyone is on the same page for design intent and project needs.

Utilize Specialized Software

Deploy advanced CAD software to generate accurate and detailed shop drawings. These cutting-edge tools enable the use of annotations, precise modeling, and documentation to ensure information richness and accuracy.

Review and Approval

Conducting extensive reviews and approvals from various project parties, such as architects and engineers, before the final shop drawing set is prepared improves accuracy, completeness, and adherence to required specifications. This step reduces errors during construction.

Shop Drawing Success Stories

The client was an engineering contracting company specializing in engineering consulting and contracting. With 2D drawings supported by markup drawings, the team at TrueCADD built coordinated MEPF models with accurate shop drawings for the Irish hospital project.

The client was a BIM consultant who partnered with TrueCADD for a clash free plant room layout project in Europe. 2D files in PDF format and the manufacturing details of MEP components were provided as input. The team at TrueCADD analyzed the client input and created deliverables that included Revit models, MEP shop drawings, and 3D rendered images.

Conclusion

To conclude, the importance of shop drawings in construction projects is not overstated. Accuracy, extensive detailing and compliance with project specifications lower liabilities and risks.

By serving as a communication tool for various stakeholders, these drawings illustrate clarity, mitigate misunderstandings, and improve the overall efficiency of the project. Embracing the use of shop drawings showcases compliance within a collaborative system to ensure on-time and successful project delivery. Construction professionals need to embrace the transformative capabilities of shop drawings to reduce risks and enhance standards of building excellence.

FAQs Related to Shop Drawings

-

No, construction drawings are not the same as shop drawings, as shop drawings are detailed, enriched with specific information about prefabricated components or equipment. Construction drawings illustrate overall project specifications and plans.

-

Shop drawings include information on dimensions, material specifications, fabrication techniques, and installation rules for prefabricated components. The information within shop drawings ensures precise communication between contractors, manufacturers, and other project stakeholders.

-

Shop drawings use accurate 3D modeling and detailing to identify interferences between building components that allow for accelerated issue detection before actual construction starts. This saves resources and time during the project.

-

Yes, shop drawings are used to estimate the cost of construction materials through accurate and detailed quantities, dimensions, and specifications to enable precise cost calculations for budget and procurement.

-

Yes, shop drawings are a valuable reference tool for renovations and future maintenance, as they offer detailed insights within original construction, its components, and installation techniques. This fuels faster and more efficient repairs, modifications and replacements in various phases of the construction building.

-

Shop drawings can be modified during the construction process to include or address unforeseen changes. Being in a digital format allows for quick and simple revisions to ensure adaptability to changing project needs while maintaining accuracy and conformance to specifications.

-

Coordinated shop drawings in construction projects refer to integrated plans that illustrate building components to ensure seamless alignment. These drawings are meticulous through collaboration and clash identification to enhance coordination, improve efficiency, and minimize onsite changes.

-

The time to prepare shop drawings for a construction project varies according to project scope and complexity. The time can range from weeks to months, as it involves meticulous planning, coordination between various trades and exhaustive drafting.

-

Design professionals, such as architects, engineers, and contractors, use advanced software such as AutoCAD and Revit to generate accurate and detailed shop drawings. These tools support 3D modeling, accurate measurements, and project-wide collaboration to ensure the creation of high-quality and information-rich shop drawings.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.