The integration of DriveWorks into SolidWorks allows retail store furniture manufacturers to automate and personalize the configuration, design and production of their furniture. This helps cut down errors, provide cost savings, and improve customer satisfaction.

info@truecadd.com

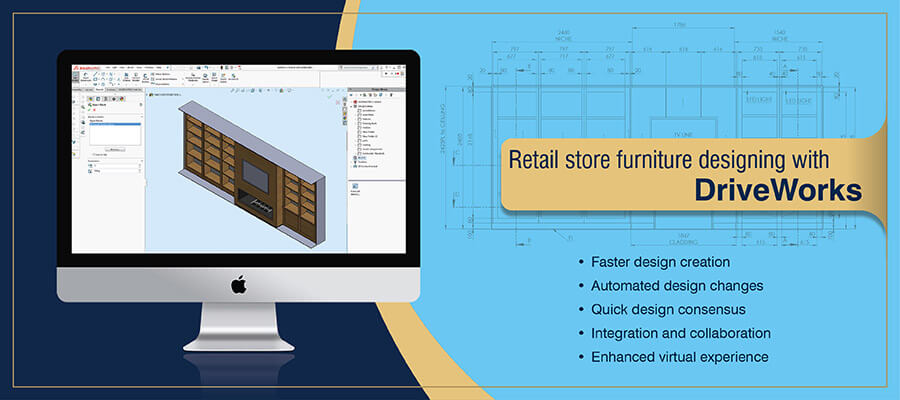

5 Benefits of DriveWorks for Retail Store Furniture Manufacturers

Table of Contents

Retail store furniture manufacturers need to find a balance between a customer’s requirement for bespoke furniture and an efficient, high-quality production process. DriveWorks for furniture manufacturers allows them to do this with its advanced features and workflows.

Furniture manufacturers supplying retail stores face routine challenges when it comes to creating customized furniture, meeting changes in retail store layouts and updating branding on a daily basis. In such situations, DriveWorks design automation for furniture, integrated with SolidWorks, helps them automate custom furniture configurations. This enables sales staff and customers to view and approve custom furniture design prototypes at speed.

This is how DriveWorks helps furniture manufacturers increase productivity and reduce errors and rework time and costs. It enables furniture manufacturers to develop more customized product offerings, giving them a sharper edge in the retail furniture market.

Here, we take a look at 5 advantages that furniture manufacturers in the retail furniture industry can expect by using DriveWorks in their businesses.

Overview of design automation in the furniture manufacturing industry

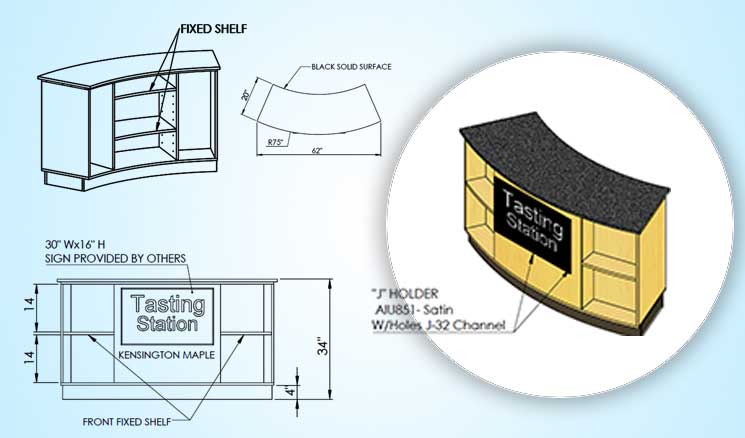

Retail furniture design process has always been labor intensive and iterative, requiring the involvement of designers, engineers, and sales representatives. Because any CAD design automation utilizes software to automate repetitive design functions, create versions of existing CAD designs using defined parameters/rules, and integrate manufacturing data into the CAD design model.

CAD automation tools for furniture manufacturing enable users to define various product options, generate sales presentations, create shop drawings and prepare CNC machining information with little manual input. A furniture product configurator streamlines this process by allowing customers and sales teams to visualize and customize designs according to specific requirements. CAD tools thus reduce design to production time and increase accuracy.

That is exactly how DriveWorks assists your project.

DriveWorks enables users to effectively manage large, customized projects through automated repetition of tasks and the ability to scale the creation of custom designs using parametric modeling in SolidWorks, allowing retail furniture manufacturers to stay ahead of their competitors.

What is DriveWorks?

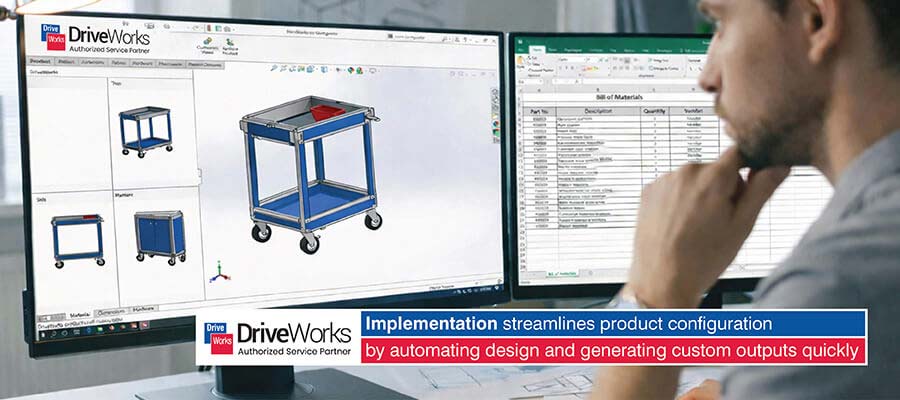

DriveWorks works as custom furniture manufacturing software that links into SolidWorks. The integration of DriveWorks into SolidWorks provides a method of creating new products and configurations through the use of logic and rules based engineering which in turn reduces the amount of time spent on manually completing these tasks.

The primary method used by DriveWorks to capture design intent is rules-based engineering and logic. This process creates variations from the same basic model eliminating the need to remake the model for each custom ordered product.

DriveWorks offers a furniture product configurator specifically for the retail furniture industry. This provides manufactures the ability to automate all processes of design, pricing, product customization and data management.

DriveWorks has three modules for configuring products: DriveWorks Pro, DriveWorks Solo and DriveWorksXpress. These applications provide varying levels of automation depending upon the business requirements for the manufacturer.

DriveWorks’ configurable product features for retail furniture enable manufacturers to create cost savings, and provide customers with a greater selection of products while maintaining fast and accurate delivery.

Top 5 benefits of DriveWorks for retail store furniture manufacturers

Using design automation is an advantage in the retail furniture manufacturing marketplace. Below are five key benefits of utilizing DriveWorks to make your company’s manufacturing methods flexible, customer-centric and modern.

1. Streamlining customization for retail store furniture

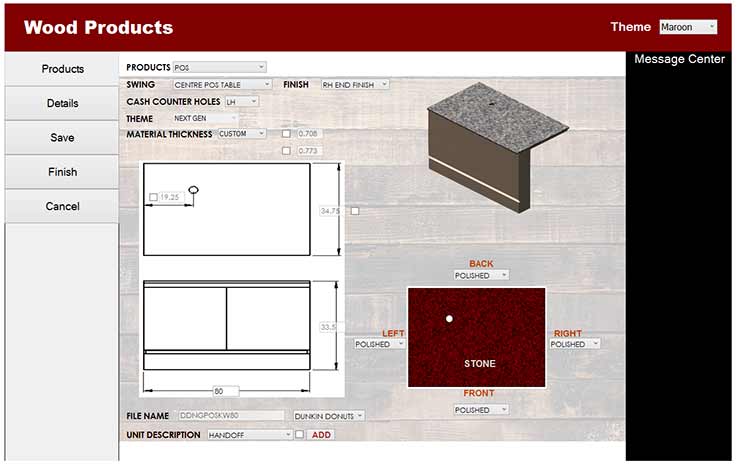

Customization is essential in the retail furniture industry as each retailer needs to meet specific branding, functional, and space requirements. The customization capabilities of DriveWorks provide a tremendous benefit in this area due to its ability to automate the use of rules-based logic for configuration.

Using powerful product configurators you can reduce design hours and streamline your operational workflow. DriveWorks can take any static 3D model and turn it into a configurable design model. Configurable elements of the model may include dimensions, material types, finishes and assembly options.

This automated furniture design process allows retailers to create furniture in real-time and receive immediate feedback regarding the feasibility, pricing and lead times associated with each selection. By automating the design-to-manufacturing workflow is simplified and the potential for errors caused by manual entry or miscommunication is reduced.

Key gains

- Automatically completes custom design activities and reduces the amount of work involved in those processes.

- Effectively manages large quantities of custom orders.

- Produces automatic configurations for designs which results in faster design completion and reduced lead times.

DriveWorks design automation for a metal & wood furniture manufacturer

A U.S.-based custom metal and wood furniture manufacturer had issues with creating 2D drawings due to the high number of products being produced and long (4-5 days) engineering lead times. Manual repetitive processes and lack of automation caused errors and long responses to customers and architects requesting products.

TrueCADD created a DriveWorks Configurator with SolidWorks that generated 3D models and all associated manufacturing drawings and quotes using user defined input on the front-end. The new process provided quicker turnaround time for decisions and also allowed access to design data across departments.

The results were:

- 4-5 day engineering lead time reduced to 1 day

- 70x faster design cycles

- Improved quality and consistency across custom furniture outputs

Automate your design process with expert DriveWorks solutions today.

Contact our experts »2. Improving design accuracy and reducing errors

A major challenge in the furniture manufacturing industry is achieving accurate designs for customized items. The use of 3D CAD automation for furniture allows for the implementation of standardize rules-based design processes that can minimize or completely eliminate potential errors with manual design processes.

The use of automation through DriveWorks reduces design inconsistencies as well as rework needed to correct such issues. For instance, DriveWorks will check design elements to assure they are in line with predetermined limits and constraints that reflect the manufacturer’s capabilities and the materials available to be used.

CAD drafting services use design automation to minimize errors and also improve the communication between the design and manufacturing departments. This streamlines production and ultimately enhances customer satisfaction.

Key gains

- Automate repetitive tasks that could have human error if done manually.

- Ensure high-quality throughout all custom-made products.

- Reduce the amount of rework, save time and resources.

DriveWorks design automation for 3D furniture modeling

A manufacturer of retail store fixtures utilizing legacy 2D drawings experienced high rates of material waste, design errors and long lead-times in their production processes. The company was looking for a fast and efficient method to generate manufacturable 3D designs and scale custom orders from sketches.

TrueCADD developed an integrated 3D CAD / configurator using DriveWorks, which automated 3D designs creation, flat pattern drawings and manufacturing documentation. TrueCADD used DFM (Design For Manufacturing) methods to help accelerate the design-to-production cycle.

The results were:

- A reduction in monthly design errors

- Reductions in design-to-production cycles

- A library of reusable furniture models for use in future custom orders

3. Scaling production capabilities for mass customization

Balancing a large-scale production process with an individualized approach to meet the customer’s needs is crucial furniture manufacturers. And, DriveWorks has tools that allow customers to use mass customization in furniture design processes.

With the use of DriveWorks, manufacturers can create a family of products that are customized based upon a set of predefined rules or logic. This means you can easily create hundreds of different design options without having to manually redesign each option. With this ability to scale, you will be able to build a high volume of custom furniture designs as requested by the individual customer.

DriveWorks also provides a seamless flow of data from design through to manufacturing. The result is no longer having to enter the same information multiple times (manual data entry), and you can still perform mass customization while maintaining your production efficiency, quality, and profit margins.

Key gains

- Mass customization without an increase in the cost of producing your items.

- The ability to batch process many design variations.

- Scaling up production to meet high demand with consistency.

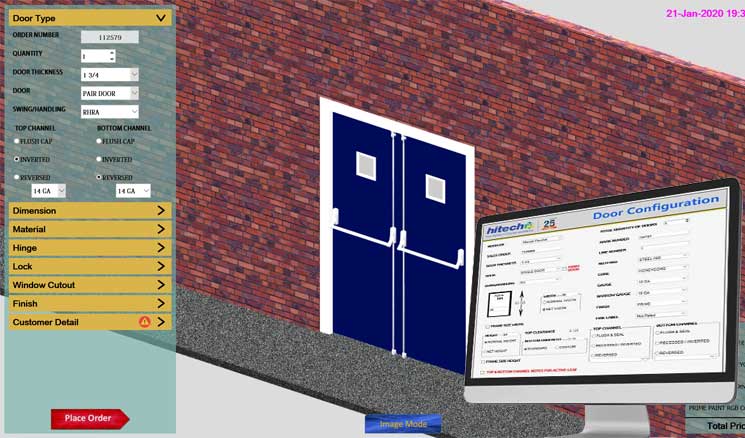

Metal doors & frame design customization in DriveWorks, USA

A U.S.-based manufacturer of hollow metal doors and frames was using multiple spreadsheet documents, undefined processes for creating a custom order and repetitive manual drafting activities which caused delay and error. The customer required an efficient engineering process to reduce the time it took to produce orders and increase the quality of its products.

TrueCADD created a custom door configurator using DriveWorks in SolidWorks that produced 3D models and manufacturing drawings based on the customer’s input. The company used logical rules and a single data base to ensure consistency and speed in the production of production ready documentation.

The results were:

- Reduction of design time by 70%

- Increase in first-time correct designs

- More than 70,000 custom doors and frames designed and documented

Customize your DriveWorks experience with tailored plugins.

Contact us now »4. Save on production costs with resource efficiency

Material cut lists and nest patterns can be generated accurately by DriveWorks; these results in cost reductions from the amount of waste generated. Particularly when it comes to sheet goods such as plywood and MDF that are common to many types of retail furniture, reducing waste will have a direct positive impact on your profit margin.

The precision provided by DriveWorks also applies to hardware. The automated Bill Of Material (BOM) generation process in DriveWorks is the reason why you won’t need to buy excess hinges, handles and fasteners for every project; instead you just buy what you need and therefore there is less storage space needed.

DriveWorks enables you to create standardized designs while providing a streamlined manufacturing workflow for the product. This results in a reduction of costly errors/rework on the shop floor and also reduced down time that otherwise happen due to unnecessary manufacturing problems.

Key gains

- Reduced waste of material, resulting in lower production costs.

- Reduced manual labor to automate repeat activities.

- Resources are utilized at maximum levels during all phases of the production process.

5. Customer experience and sales improvement

The design automation and Configure, Price, Quote (CPQ) solutions that DriveWorks provides for both sales teams and their end-users, enables them to customize furniture products of complexity that would be difficult to do manually.

DriveWorks configurator benefits the customers by automating the quotation-to-order process. Therefore, companies manufacturing furniture can display real-time images of custom furniture designs as well as produce immediate quotes; thus eliminating the delay between an inquiries to confirm the order.

By streamlining the quote-to-order process, it allows salespeople to devote themselves to developing strong relationships with customers, as well as consulting on custom designs. Offering such customization options at high speeds has become a major differentiator in the highly competitive furniture retail industry; which ultimately leads to increased sales and improved levels of customer satisfaction.

Key gains

- The ability to respond to inquiries quickly through the quote-to-order process.

- Customer interaction increases through the use of a custom furniture configurator.

- Conversions increase due to quick quotations.

Conclusion

DriveWorks for furniture manufacturers enables the customization of designs for each and every customer’s specifications throughout the entire production process. When DriveWorks is integrated into SolidWorks, furniture manufacturers can achieve major efficiencies through streamlining their production processes.

As a result of these improvements manufacturers can deliver their products quicker, at lower costs and provide customers with greater satisfaction.

In response to the increasing demand from consumers for premium, custom-furniture, manufacturers are now using DriveWorks automation for furniture design. This also provides them an opportunity to strategically invest in technology that will prepare them for the demands of the future.

FAQs about DriveWorks for furniture manufacturers

-

DriveWorks in integrated within SolidWorks. So you can create custom designs that follow pre-determined design rules and parameter settings. This is excellent for complicated and customized pieces.

-

Yes, DriveWorks was created to help companies that need to produce large quantities of custom furniture. By creating the same number of variations in a short amount of time, you will have better consistency and accuracy and will be able to complete a larger number of projects in less time.

-

By using DriveWorks, you can reduce the costs and waste generated in your production process through automation of repetitive tasks, optimization of raw materials and reduction of manual labor involvement. This results in a more productive and cost effective manufacturing process.

-

You can implement DriveWorks by developing design rules, product configurations and automation workflows in your SolidWorks environment. Afterward, you can expand the use of DriveWorks as needed to meet the demands of your production operations.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.