Millwork drafters face a fragmented software market in 2025. There are over 50 CAD tool options, but only six actually matter for real production. Each tool claims to be the complete solution, but the reality is you’ll probably need 2-3 programs to handle everything from initial design to CNC output.

info@truecadd.com

Best Drafting Tools for Millwork in 2025

Table of Contents

The best millwork drafting software in 2025 are AutoCAD, Autodesk Inventor, SolidWorks, Microvellum, Cabinet Vision, and 2020 Design. While AutoCAD runs everywhere, Microvellum rules the bigger operations, and Cabinet Vision sits perfectly in the middle.

CAD tools range from basic AutoCAD LT to full Microvellum packages with all the bells and whistles. The secret is about matching tool capabilities to your actual workflow. I have seen two-man shops blow money on software they never touch. Meanwhile shops running CNCs waste hours per project because they cheaped out on CAM integration.

Walk through any millwork shop district and you will see patterns. AutoCAD everywhere you look, Inventor growing in commercial work, SolidWorks in the high-end custom shops, Microvellum running the big facilities, Cabinet Vision in mid-size operations, 2020 Design owns the kitchen showrooms.

There is no shortage of drawing tools for millwork drafting services in 2025. But here is the thing – picking software that matches your shop’s workflow beats chasing the fanciest features. Let’s dig into why.

What Makes a Drafting Tool Ideal for Millwork?

Running a millwork shop means juggling 2D CAD drawings (most arrive as DWG files), contractor PDFs, and field sketches on napkins, renders that actually sell, and CNC files that run your machine and won’t ruin it.

You need both 2D and 3D drafting capabilities, obviously. And, beyond compatibility, you are looking for parametric modeling, automated documentation, and precision detailing that actually work.

Stop looking at features lists. Here is what determines if you will see ROI or kick yourself :

- 2D and 3D that actually talk to each other saves you hours versus separate programs.

- Parametric design means changing that cabinet from 24″ to 27″ updates everything – doors, shelves, hardware – automatically.

- Component libraries with thousands of parts cut design time versus starting from scratch every time.

- CNC/CAM integration that works out of the box saves money on post-processors plus programming time per sheet.

- Material optimization that maximizes usage saves real money on plywood monthly.

- Shop drawings in one click beats hours of manual drafting per kitchen.

The right tool must import DWG clean, scale from single vanities to apartment towers, handle 2D shop drawings and 3D models equally well, spit out G-code your specific CNC understands, optimize material yield on expensive plywood, and crank out shop drawings fast.

Popular CAD drafting tools for millwork

AutoCAD

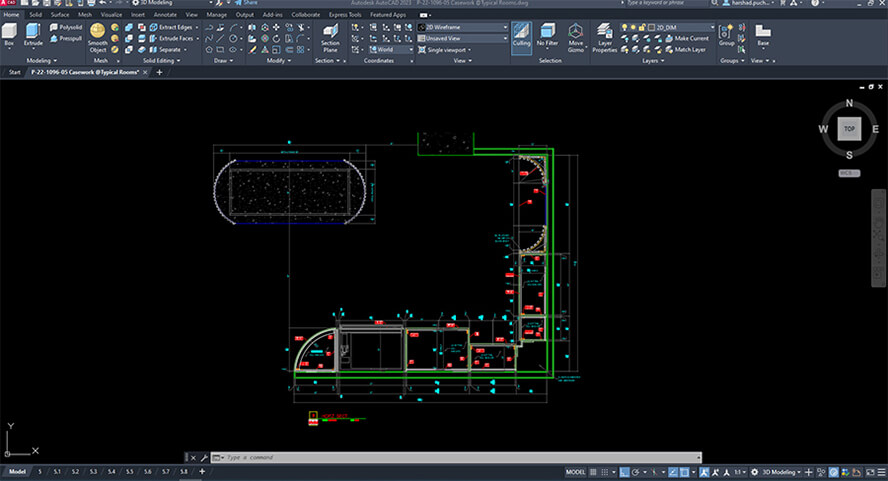

AutoCAD for millwork casework drawings

AutoCAD for millwork casework drawings

In the millwork sector more than 80% of workshops use AutoCAD. You need it because architects send you DWG files. Contractors want DWG submittals. Permit offices demand DWG uploads. No AutoCAD means you’re dead in the water.

AutoCAD means you work in the architect’s native format. No conversion disasters. No missing xrefs blowing up your sheets. No font substitutions turning your dimensions into hieroglyphics.

It plays nice with other Autodesk products – Revit for BIM, Inventor for complex 3D. Third-party platforms like Microvellum run inside AutoCAD as vertical applications. Smart move, really.

The latest updates added AI-powered markup assist – converts redlines to geometry faster than doing it manually. Smart blocks keep relationships when you stretch cabinet runs. The 3D navigation finally catches conflicts before your installer calls screaming.

Here is what AutoCAD actually delivers for millwork:

- Component tracking that works: Annotative scaling keeps dimensions readable. Layers separate structure from hardware from annotations. XDATA stores material specs, hardware SKUs, finish codes right in the drawing.

- Quantity takeoffs that don’t lie: 1:1 scale means field dimensions match shop drawings within 1/16″. DATAEXTRACTION pulls cabinet counts, door styles, linear feet straight to Excel. No more material overages from bad math. This also means accurate millwork estimation for your projects.

- Design changes without tears: Grip editing updates multiple objects at once. You stretch a wall in design, the design of base cabinets follow automatically. 3D orbit catches upper cabinets hitting windows. Revision clouds with dates keep your shop floor sane.

- File formats that actually work: Beyond DWG and DXF, you get IGES for CNCs, STEP for SolidWorks, DWF for markups, PDF for permits. No more Friday panic attacks about compatibility.

Pricing

AutoCAD’s standard subscription is $1,600/yr. Includes upgrades and support.

Generate submittals and shop drawings faster with AutoCAD.

Start drafting »Autodesk Inventor

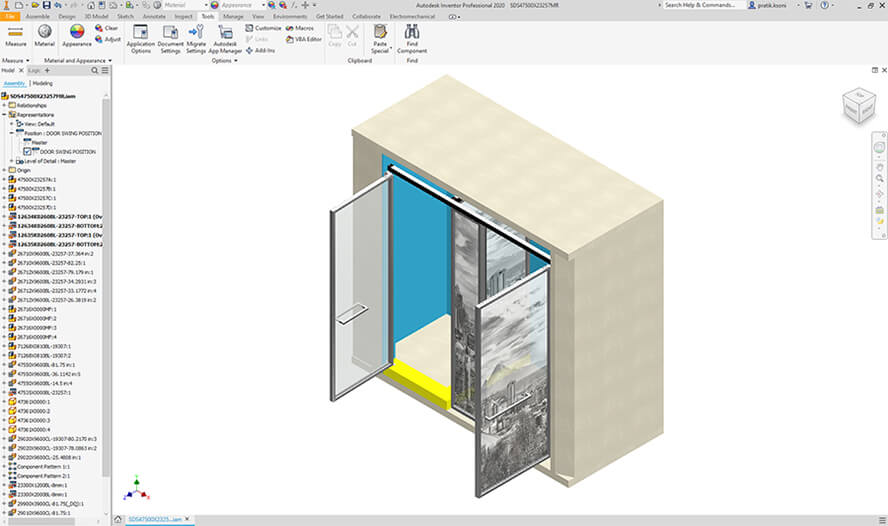

Inventor for woodwork 3D modeling

Inventor for woodwork 3D modeling

Autodesk Inventor’s builds parametric 3D models that become your single source of truth. One model generates plans, elevations, sections, details, and CNC code. Change it Monday morning; get updated shop drawings by lunch. This approach eliminates rework from drawing conflicts.

The CAM workspace in Inventor creates G-code directly – no third-party software needed. That saves on annual CAM licenses. Adaptive clearing strategies reduce actual machining time compared to traditional pocketing.

Joint options? 15 dovetail variations, 8 mortise-and-tenon configs, box joints, finger joints, multiple dowel patterns – all built in. Change material thickness, joint spacing adjusts automatically to maintain strength.

Material libraries use real wood species with accurate grain, proper densities for weight calcs, expansion coefficients for seasonal movement.

Cross-platform compatibility that works: Opens AutoCAD files natively, exports to SolidWorks via STEP, shares through Autodesk cloud. Your CNC guy gets exactly what you designed.

Autodesk Inventor benefits the woodwork industry specifically through Woodwork for Inventor (W4I).

Here’s how W4I turns generic Autodesk Inventor into millwork specific solution:

- W4I brings grain direction management, automatic edge banding with proper miters, drilling database with hardware patterns from Blum, Grass, Salice.

- Material tracking uses current lumber prices. The optimizer nests considering grain direction. CNC operations include material-specific speeds to prevent melted edge banding.

- With a large user base globally, you get established practices, YouTube tutorials everywhere, active forums. The Scandinavians run much of their furniture industry on W4I.

Pricing

Inventor has monthly/yearly pricing plans that start from $305 per user/month to $7,320 per user/3 years. You can also go for pay-as-you-go plans where you can purchase tokens for daily use.

Discover the Secrets to Boost Your Productivity with Autodesk Inventor!

Learn how to:

- Master parametric modeling for lightning-fast design changes

- Harness the power of assembly modeling for flawless fit and function

- Create a standardized parts library to streamline your workflow

- Leverage advanced sketching tools to bring your designs to life faster

- Automate drawing creation to save precious time

- Utilize rendering and visualization to impress clients and win more projects

SolidWorks

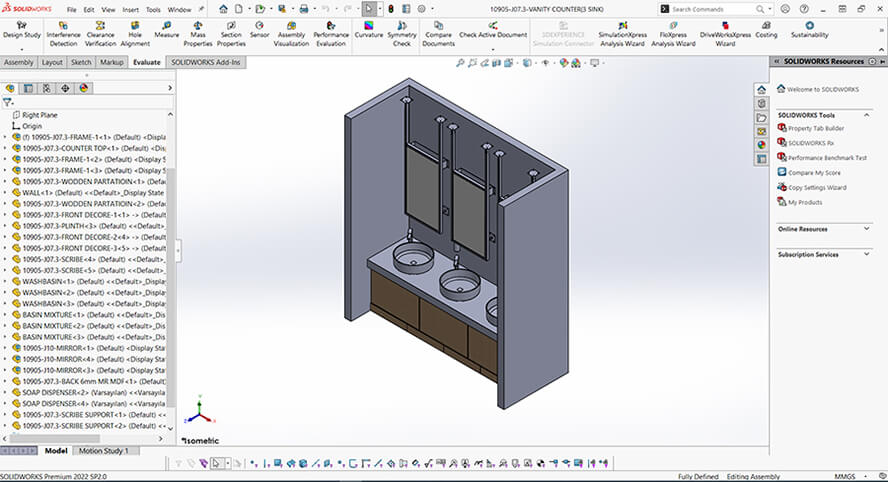

SolidWorks for millwork 3D modeling

SolidWorks for millwork 3D modeling

SolidWorks manages complex assemblies in millwork where everything stays connected. Change cabinet depth – shelf pins, drawer slides, back panel dados all update instantly. Saves hours of manual checking per revision that absolutely murders profitability.

Top-down assembly starts with room dimensions, breaks to cabinet runs, then individual boxes. Using the 3D modeling features you can also easily find conflicts in design like if upper cabinets are blocking windows, toe kicks hitting HVAC. These are the field fixes you dodge

Change base cabinet height from 34.5″ to 36″ for ADA? Every related component updates. No checking dozens of pieces hoping you caught them all.

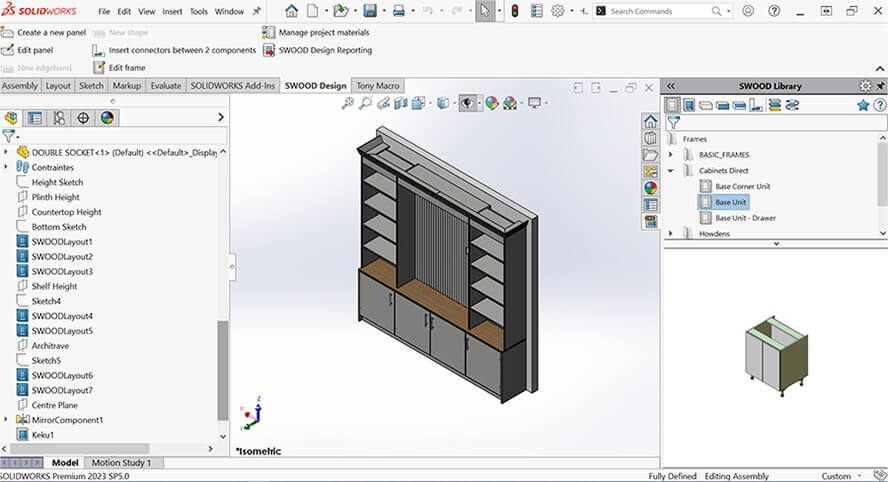

SWOOD Design add-on makes SolidWorks ready for woodworking.

SolidWorks SWOOD 3D modeling

SolidWorks SWOOD 3D modeling

- Features: Parametric assemblies enforce your shop standards everywhere. Material management tracks board footage and sheets real-time. Automatic export creates cutlists, hardware schedules, edge reports, CNC programs. Grain direction control per component. Panel thickness set globally. Blum/Grass/Salice libraries integrated.

- Benefits: The automation in SWOOD design reduces the effort within your designs, to allow you to create production-ready designs quicker. It can be used for a variety of woodworking projects like kitchens, bathrooms, shop fitting, vehicle interiors. Most shops see faster design-to-production after the learning curve.

Pricing

SolidWorks licensing is fairly simple, with a standard license being a 1-time charge of $3,995 and $1,295 a year after. It also offers a premium license $7,995 and $1,995 a year after.

Design complex custom millwork with SolidWorks + SWOOD.

Get in touch with us »Industry specific millwork drafting tools

Beyond general CAD, these tools target millwork projects and production specifically.

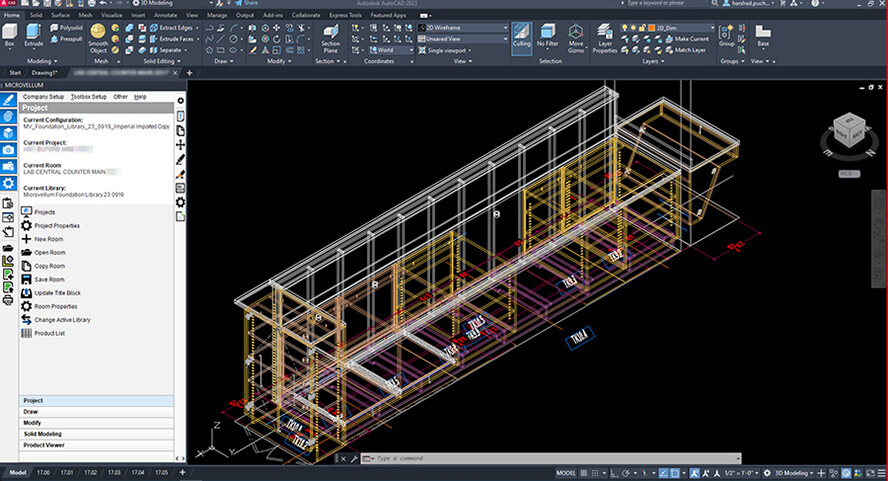

Microvellum

Microvellum for woodwork design drafting

Microvellum for woodwork design drafting

Microvellum combines CAD, CAM, and CIM in one platform inside AutoCAD. Shops with serious revenue run everything through it – residential kitchens to commercial projects. Pre-configured products from industry catalogs. Fully customizable libraries for your methods.

Outputs to Biesse, Homag, SCM, Weeke, and other CNC brands without post-processor fees. Build libraries yourself or hire a consultant to configure professionally. Report designer creates shop packets matching your exact workflow. They actually listen to user feedback for updates.

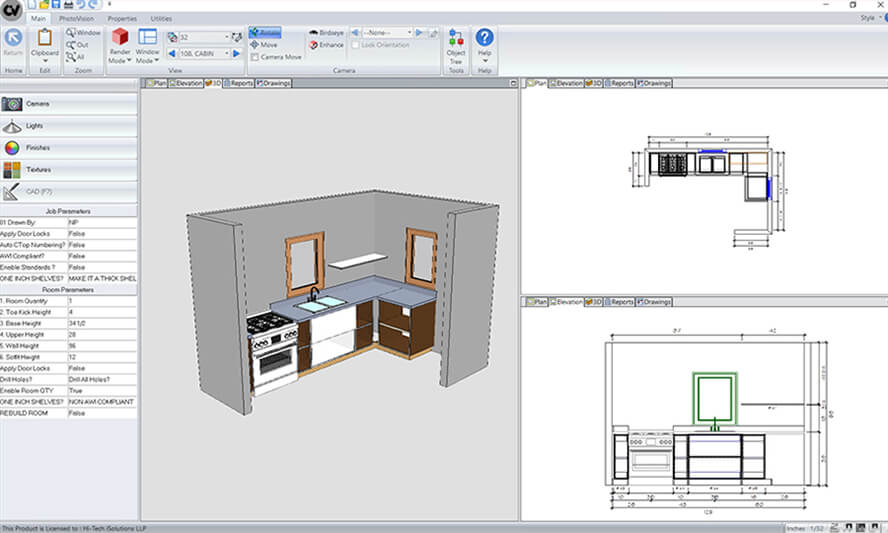

Cabinet Vision

Cabinet vision used for specifically modeling cabinets

Cabinet vision used for specifically modeling cabinets

Cabinet Vision serves thousands of shops globally by focusing on speed from design through manufacturing. One database – design, bidding, costing, production. No re-entering data.

Screen-to-Machine shows readable part names on nest patterns. Your operator sees “Left Gable Kitchen Island” not “Part_1847”. Photo-realistic renders help close more sales than simple 2D millwork shop drawings. Recent updates added JavaScript for custom programming – no proprietary languages.

Shops doing multiple kitchens monthly often see complete ROI quickly. Documentation generates automatically – huge for small shops without dedicated drafters.

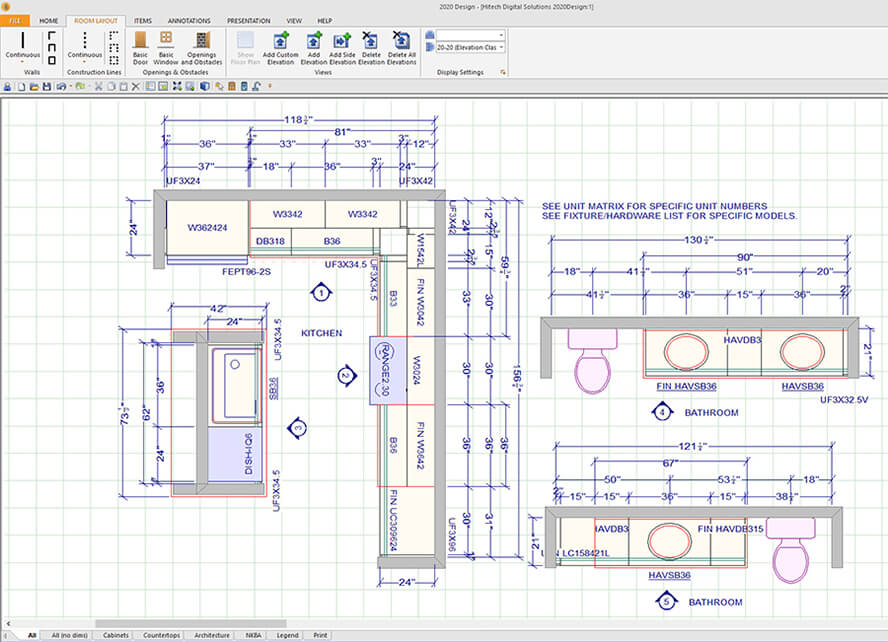

2020 Design Live

2020 Design Live helps to create kitchen and bathroom drawings

2020 Design Live helps to create kitchen and bathroom drawings

2020 Design runs in kitchen showrooms everywhere with catalogs from manufacturers – real-time pricing and availability included. Code compliance checks clearances and work triangles automatically. Catches expensive mistakes before installation.

3D visualization renders photorealistic images quickly. 360-degree panoramas work on phones – clients review anywhere. Advanced lighting calculates actual lumens on work surfaces, not just pretty pictures. SketchUp integration adds custom elements within manufacturer standards. VR through Oculus lets clients walk through before ordering.

Conclusion

Pick your millwork drafting tools based on your actual workflow, not its attractive capabilities. Your project type should determine your choice of tool.

Complex 3D assemblies? You need SolidWorks or Inventor for real parametric control. Standard 2D shop drawings? AutoCAD remains the standard for industry compatibility. Specialized millwork? Microvellum’s depth or Cabinet Vision’s speed, depending on your volume.

Real costs include software price, training per user, annual maintenance percentage of purchase, and whether your team will actually adopt it. Expensive software collecting dust helps nobody.

FAQ on CAD Drafting Tools

-

SketchUp wins for learning curve – push-pull modeling, vast 3D warehouse of furniture and cabinet parts. Beginners design their first cabinet quickly. Free web version handles basic residential projects. For production, Cabinet Vision Essentials or Microvellum Foundation includes guided workflows for common cabinets. Video training covers complete projects faster than learning full versions.

-

Yes. SolidWorks with SWOOD outputs G-code and DXF for most CNC routers. Inventor’s CAM workspace handles 3, 4, and 5-axis machines. Microvellum and Cabinet Vision include post-processors for Biesse, Homag, SCM, Weeke, Anderson, Komo, Thermwood, and others. Export keeps tool assignments, feed rates, depth settings intact. Eliminates manual programming per sheet that causes crashes and broken bits.

-

Yes. Autodesk Inventor, SolidWorks, Microvellum and Cabinet Vision handle both with different configs. Architectural millwork needs field accuracy and IFC coordination. Furniture needs aesthetic tools and ergonomics standards. All support parametric design for quick adjustments, accurate material specs, automated shop drawings. Same software designing hotel lobbies builds conference tables – it’s configuration, not capability.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.