Custom product design market demands product manufacturers to optimize overall product design costs and offer excellent product quality to stay competitive. Outsourcing your CAD drafting is the winning formula to bridge the skills and technology gap to optimize product design development and control costs.

info@truecadd.com

How Outsourcing CAD Drafting Reduces Product Design Development Costs

Table of Contents

- Costs of product design and development

- Reducing costs through outsourcing CAD drafting in product design

- Outsourcing CAD drafting to streamline design efficiency and turnaround time

- Scalability and risk mitigation through offshore CAD drafting team

- Access to advanced technology and expertise in CAD drafting

- Focusing on core business operations through outsourcing

- Quality assurance and industry compliance with outsourced CAD drafting

- Long-term strategic partnerships in CAD service

- Addressing concerns and myths in offshore mechanical CAD drafting

Within the manufacturing space, custom and discrete manufacturing is evolving rapidly. Companies manufacturing products like furniture, millwork, and fabricated sheet metal products seek methods to enhance efficiency and reduce costs for product design development. For this, they have prioritized comprehensive design drafting with precision.

The concept of outsourcing CAD drafting has proven to be a strategic move to reshape the way these industries approach product design and development. Outsourcing CAD drafting is not just a trend, but a significant lever for reducing product design development costs.

Costs of product design and development

On an average, total cost of developing modest and simple products is $30,000. This includes costs of designing, prototyping, testing, and launching the new product. Product design development costs go on increasing as the design complexity rises. Sometimes these costs go up to thousands of dollars just for development.

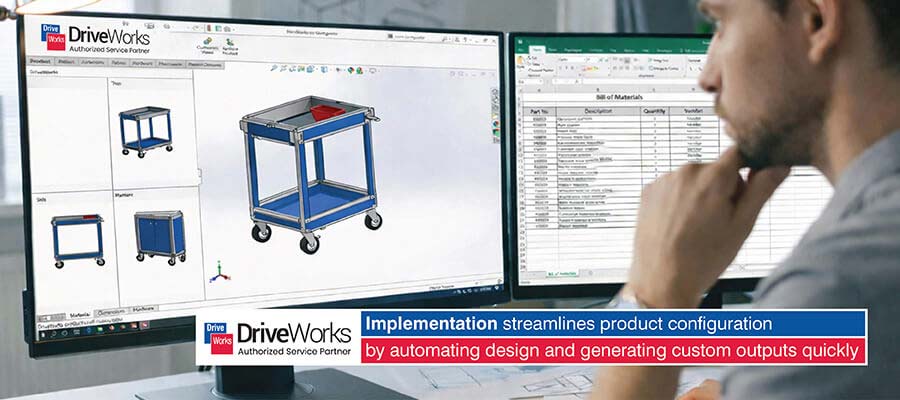

Collaborating with a CAD outsourcing company, custom product manufacturers can unlock new levels of cost-effectiveness and innovation. They get access to automation and transformative solutions for their businesses and thrive in a competitive marketplace.

Reducing costs through outsourcing CAD drafting in product design

When evaluating the cost implications of CAD drafting, it’s essential to consider both direct and indirect expenses. In-house CAD drafting involves not only the salaries of the draftsmen but also the associated costs of recruitment, training, and retention. In contrast, outsourcing CAD drafting to specialized firms offers a more streamlined financial model. These firms often have a team of experienced draftsmen, eliminating the need for extensive training and recruitment processes. Additionally, outsourcing can lead to cost savings in terms of reduced overheads, as the responsibility for equipment, software, and workspace shifts to the service provider

Initial setup and software costs

Setting up an in-house CAD drafting team requires significant initial investment. This includes purchasing high-end computers and licenses for sophisticated CAD software, which can be prohibitively expensive. Moreover, these costs are not one-time; they recur with software updates and hardware upgrades.

Outsourcing, on the other hand, transfers these expenses to the service provider, who typically has the latest technology and software, ensuring that clients benefit from advanced tools without bearing the full cost.

Staffing: Salaries, training, and benefits for in-house teams

Staffing costs for in-house CAD teams is a substantial ongoing expense. It encompasses not just the salaries, but also the costs associated with employee benefits, training, and development. The need for continuous training to keep up with evolving CAD technologies adds to the expense. In contrast, outsourcing firms are responsible for the training and development of their staff, allowing client companies to bypass these costs and complexities.

Outsourcing: Flexible pricing models, no overhead for training and/or infrastructure

One of the most appealing aspects of outsourcing CAD drafting is the flexibility it offers in terms of pricing. Outsourcing firms often provide various pricing models, such as per-project or hourly rates, allowing for better cost control and predictability.

This flexibility in CAD services is particularly beneficial for custom product manufacturers who deal with variable workloads. Additionally, outsourcing eliminates the need for investment in training and infrastructure, as these are managed by the service provider, leading to significant savings in both time and money.

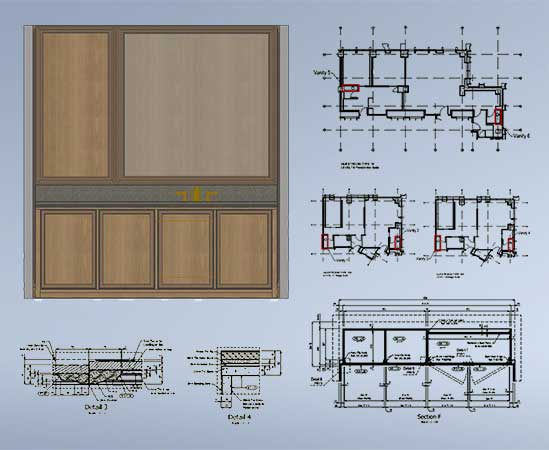

Reduced 70% design cost with Inventor iLogic for a vanity unit manufacturer

A marine furniture manufacturer based in Ireland was facing challenges to generate generating furniture drawings that were compatible with iLogic. They also lacked effective communication for timelines, revisions etc. with five different engineers working on the team. This resulted in costly mistakes for product design and drafting.

By collaborating with TrueCADD’s offshore CAD drafting team, a proper communication mechanism was set up. It enabled streamlines design flow request and reduced change order. Overall, the manufacturer could reduce 70% of the project cost.

Vanity Unit CAD Model and Design Drafting

Vanity Unit CAD Model and Design Drafting

Vanity Unit Model and Detail CAD Drawings

Vanity Unit Model and Detail CAD Drawings

Outsourcing CAD drafting to streamline design efficiency and turnaround time

Outsourcing CAD drafting streamlines the design process in several ways. Firstly, it allows manufacturers to bypass the time-consuming steps of recruiting and training in-house CAD drafters. By leveraging the expertise of specialized outsourcing firms, manufacturers can immediately tap into a ready pool of skilled professionals. These firms often employ advanced project management tools and methodologies, ensuring that CAD drafting tasks are completed swiftly and accurately.

Especially for furniture manufacturers specializing in retail store furniture, who have an ongoing need for CAD drafting benefit the most from outsourcing CAD drafting. Furthermore, outsourcing firms can operate in different time zones, enabling round-the-clock work cycles that expedite project completion.

Access to a larger pool of specialized expertise

One of the significant advantages of outsourcing is the access it provides to a diverse range of specialized expertise. Manufacturing companies can significantly improve manufacturing efficiencies with CAD engineering outsourcing. Typically employ a team of professionals with varied skill sets and experience in different CAD drafting niches. This diversity enables them to handle complex and varied project requirements more efficiently than a standard in-house team. For custom product manufacturers, this means that no matter how unique or specialized their CAD drafting needs are, they can find the right expertise through outsourcing, leading to better quality designs and faster project execution.

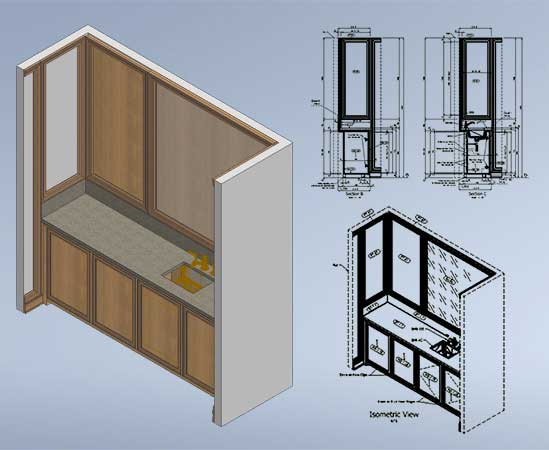

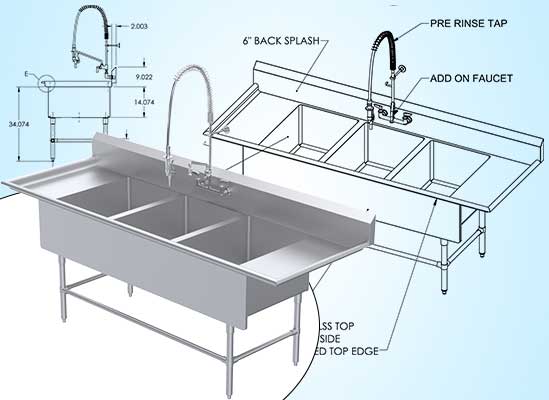

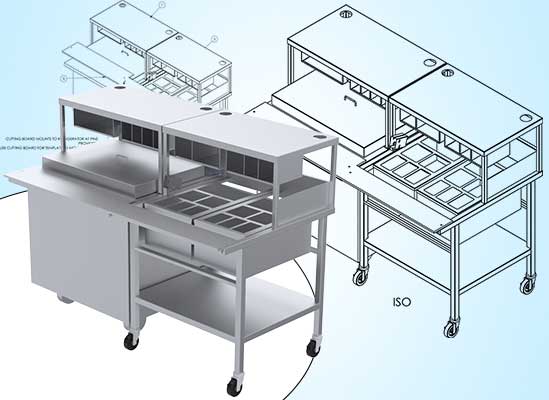

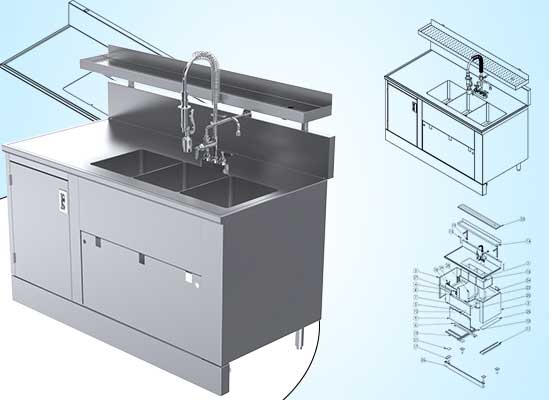

CAD drafting specialist for stainless steel furniture accelerated design detailing by 50%

The impact of outsourcing on project turnaround times is not just theoretical but is evidenced by numerous real-world examples. For instance, a leading millwork furniture of stainless-steel manufacturer reported a 50% reduction in shop drawings development time after switching to an outsourced CAD drafting model.

Stailess Steel Compartment Sink Cabinets

Stailess Steel Compartment Sink Cabinets

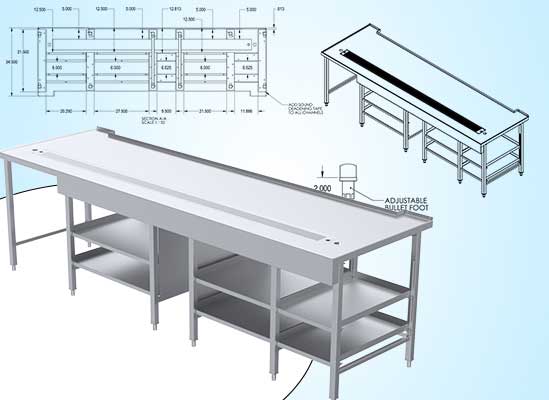

Millwork Drafting for Commercial Kitchen Unit

Millwork Drafting for Commercial Kitchen Unit

MillWork Detailing for Commercial Work Table

MillWork Detailing for Commercial Work Table

MillWork CAD Drawings for Restaurant Kitchen Sink

MillWork CAD Drawings for Restaurant Kitchen Sink

These examples underscore the tangible benefits of outsourcing in accelerating project timelines, allowing manufacturers to respond more quickly to market demands and opportunities.

Scalability and risk mitigation through offshore CAD drafting team

One of the key enablers for scalability for businesses in the product manufacturing sector is offshore CAD drafting team. It allows manufacturers to adjust their design capabilities in response to fluctuating market demands without the constraints of fixed staffing levels and infrastructure.

When a business experiences a surge in demand, outsourcing partners can quickly ramp up their services to meet the increased workload. Conversely, during slower periods, companies can scale down outsourced services, thus maintaining operational efficiency and cost-effectiveness. This level of scalability is challenging to achieve with an in-house team, where fixed costs and resource limitations can hinder rapid adjustment to changing market conditions.

Risk reduction in terms of project overload and staffing issues

Outsourcing CAD drafting also plays a significant role in risk mitigation, particularly concerning project overload and staffing challenges. By leveraging the resources of an outsourcing partner, businesses can avoid the pitfalls of overburdening their in-house teams, which can lead to burnout, reduced quality of work, and missed deadlines. Additionally, outsourcing circumvents the risks associated with staffing, such as the challenges of recruiting, training, and retaining skilled CAD drafters. This not only saves time and resources but also ensures that projects are not delayed or compromised due to staffing issues.

Access to advanced technology and expertise in CAD drafting

Outsourcing CAD drafting offers a significant advantage by providing access to state-of-the-art CAD software and highly skilled drafters, without the need for direct investment. This approach eliminates the substantial costs associated with purchasing, licensing, and updating advanced CAD software.

Moreover, it spares companies the expense and effort of recruiting and training drafters proficient in these sophisticated tools. By partnering with an outsourcing firm, businesses can leverage the latest in CAD technology and expertise, ensuring high-quality design output that meets contemporary standards, all while maintaining a leaner cost structure.

Outsourcing firms’ constant adaptation to the latest CAD design drafting software

A key strength of reputable outsourcing firms is their commitment to staying abreast of the latest technological advancements in CAD drafting. These firms invest in cutting-edge CAD platforms and continuously train their staff to master new features and techniques.

More than adoption of new tool, this also means using latest versions, plugins etc. for specific needs of the manufacturer. For example, using an SWOOD plugin for SolidWorks while developing woodworking shop drawings or PSCAM for manufacturing needs or Woodwork for Inventor in Autodesk Inventor.

Sometimes, it is not just plugins. It is also using specialized software for specific purposes. For example, 2020 Design is used to accelerate kitchen and bath cabinets. Likewise, there are modules too within the CAD platform for special purpose 3D CAD modeling. For instance, Sheet Metal Module in SolidWorks offer specialized features and commands to create sheet metal parts and assemblies.

This ongoing adaptation of modules, features and plugins ensures that they can offer their clients the most advanced solutions available in the market. For manufacturers, this means having access to top-tier CAD capabilities without the need for constant internal upgrades and training, allowing them to focus on core business activities while still benefiting from the latest technological advancements.

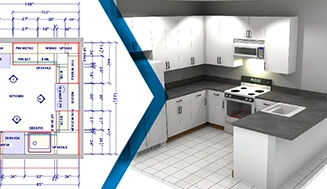

Use of 2020 Design delivered accurate production-ready models for luxury kitchen cabinets

A US-based manufacturer of kitchen and bath cabinets recorded an acceleration of 20-30% using 2020 Design. The team interpreted the architectural plans according to NKBA standards, using reference documents and handbooks. Based on this, and using specialized software for cabinet drawings, the manufacturer accelerated modeling time for kitchen millwork.

Using standard component library in 2020 Design and drag and drop feature, TrueCADD drafting teams delivered shop drawings and countertop details at a faster rate. They could also deliver accurate production-ready models.

I Shape Kitchen

I Shape Kitchen

L Shape ada Kitchen

L Shape ada Kitchen

L Shape Kitchen

L Shape Kitchen

U Shape Kitchen

U Shape Kitchen

Focusing on core business operations through outsourcing

For manufacturers, the decision to outsource CAD drafting offers a strategic advantage: the ability to concentrate on their core competencies. By delegating the specialized task of CAD drafting to external experts, companies can redirect their resources and focus towards areas where they excel, such as product innovation, market expansion, and customer service. This reallocation of focus and resources away from non-core activities helps in streamlining operations and enhancing the company’s core strengths, which are crucial for gaining a competitive edge in the market.

Impact on overall productivity and innovation within the company

Outsourcing CAD drafting not only frees up valuable resources but also positively impacts the overall productivity and innovation within the company. With the technical aspects of CAD drafting handled by specialized partners, in-house teams can devote more time and energy to strategic planning, creative design, and innovation. This shift in focus can lead to the development of more innovative products and services, improved operational strategies, and a more agile response to market changes. The enhanced productivity and innovation can drive growth and profitability, reinforcing the company’s position in the market.

A manufacturer focuses on core design development by outsourcing sheet metal detailing

A Russian metal fabricator was struggling with tight deadlines due to shorter time between input receipt and release of final drawings for manufacturing of structural metal products. As a result, they had little time for designs innovation and research.

By collaborating with TrueCADD’s drafting team, they could developed detailed 3D CAD models assembly drawings and models. They could also delivered STEP file, DXF and PDF of all the drawings. This freed up the design drafting and focus on quality to ensure custom properties for accuracy in overall dimension.

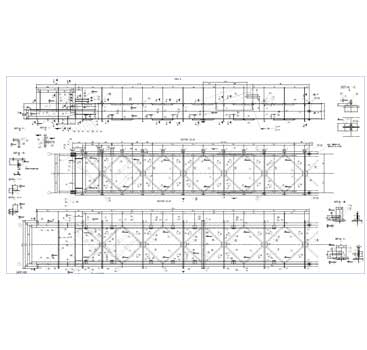

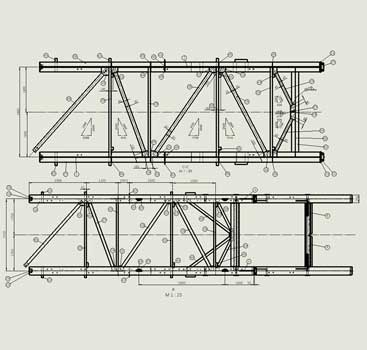

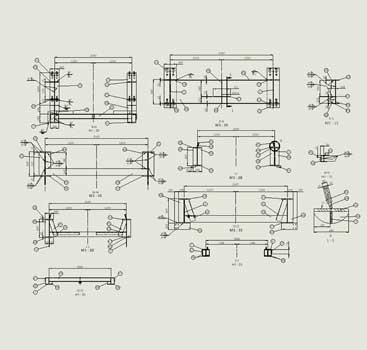

Steel Structure Shop Drawings

Steel Structure Shop Drawings

Metal Parts CAD Drawings in SolidWorks

Metal Parts CAD Drawings in SolidWorks

Metal Parts Assembly Drawings

Metal Parts Assembly Drawings

Metal Building Product 3D Model

Metal Building Product 3D Model

Quality assurance and industry compliance with outsourced CAD drafting

Outsourcing firms specializing in CAD drafting are not just service providers; they are custodians of quality and compliance. These firms understand the critical importance of adhering to industry standards and ensuring high-quality outputs. To achieve this, they employ a combination of skilled professionals, advanced technology, and rigorous process management.

Custom manufacturers should stay abreast of the latest industry standards and regulations, ensuring that all CAD drafts comply with the relevant norms and guidelines. This commitment to quality and compliance is particularly crucial in industries where precision and adherence to standards are non-negotiable, such as in aerospace, automotive, and construction.

The role of quality checks and certifications

Quality checks and certifications play a pivotal role in the outsourced CAD drafting process. Reputable outsourcing firms implement stringent quality control procedures at various stages of the drafting process to ensure accuracy and precision. These checks may include peer reviews, automated error detection, and compliance audits, among others.

Additionally, many of these firms hold certifications from recognized industry bodies, which serve as a testament to their commitment to maintaining high standards. These certifications often require regular audits and reviews, ensuring that the outsourcing firm continually upholds and improves its quality standards. By entrusting CAD drafting to a certified and quality-focused outsourcing partner, manufacturers can be confident that the outputs will not only meet but often exceed industry standards, thereby safeguarding the integrity and reliability of their products.

Read here: Four reasons why you should outsource 2D & 3D CAD drafting services

Long-term strategic partnerships in CAD service

The establishment of long-term relationships with outsourcing firms goes beyond transactional interactions, fostering a deep understanding and consistent quality in CAD drafting services. When manufacturers engage with an outsourcing partner over an extended period, the partner becomes intricately familiar with the manufacturer’s specific needs, preferences, and expectations.

A familiarity allows the outsourcing firm to tailor its services more effectively, ensuring that the CAD drafts align precisely with the manufacturer’s requirements. Over time, this relationship evolves into a strategic partnership, where the outsourcing firm acts as an extension of the manufacturer’s own team, contributing not just technical expertise but also valuable insights and suggestions for improvements.

Example of a successful long-term partnership

A notable example of a successful long-term partnership in the realm of CAD drafting involves a leading home appliances manufacturer and its CAD drafting service providers. The relationship, spanning over a decade, has been built on mutual trust, consistent quality, and collaborative growth.

The outsourcing firm has gained an in-depth understanding of the manufacturer’s design philosophy and market strategy, enabling them to provide highly customized and efficient CAD services. This deep integration has resulted in the development of several innovative appliance designs, significantly reducing time-to-market and enhancing the manufacturer’s competitive edge.

For the outsourcing firm, this long-term partnership has provided stability and the opportunity to grow and refine its expertise in line with the evolving needs of the manufacturer. The relationship has been mutually beneficial, with the manufacturer gaining from the outsourcing firm’s dedicated support and expertise. Likewise, the outsourcing firm enjoys sustained business and the chance to showcase its capabilities on a larger stage.

Addressing concerns and myths in offshore mechanical CAD drafting

Modern outsourcing practices have evolved significantly to address these concerns effectively. Regarding the fear of losing control, outsourcing firms now employ collaborative approaches that keep clients involved at every stage of the CAD drafting process. This collaboration is facilitated by advanced communication tools and project management software, allowing for real-time updates, feedback, and modifications. This ensures that the offshore mechanical CAD drafting services align closely with the client’s expectations and requirements.

When it comes to security, reputable outsourcing firms understand the importance of data protection and adhere to stringent security protocols. These measures include secure data transfer methods, confidentiality agreements, and compliance with international data security standards. Additionally, many outsourcing firms undergo regular security audits and certifications to ensure that their data handling practices are up to date and foolproof.

By addressing these concerns through transparent communication, collaborative processes, and robust security measures, modern outsourcing firms have debunked the myths surrounding outsourcing. This has paved the way for more companies to embrace outsourcing as a safe, efficient, and reliable solution for their CAD drafting needs.

Conclusion

In summarizing the key aspects of this discussion, it’s clear that outsourcing CAD drafting offers a multitude of benefits for furniture, millwork, and sheet metal manufacturers. The primary advantages include significant cost reduction, enhanced efficiency in design processes, access to specialized expertise, and the ability to focus more intently on core business operations.

Outsourcing CAD drafting not only alleviates the financial burden associated with in-house drafting teams but also streamlines the design development process. By tapping into a pool of skilled drafters equipped with the latest technology, manufacturers can ensure high-quality outputs while adhering to industry standards. This approach also allows businesses to scale their operations flexibly, adapting quickly to market demands without the constraints of staffing and resource limitations.

Furthermore, the strategic value of outsourcing extends beyond mere operational efficiency. It enables manufacturers in specialized sectors like furniture, millwork, and sheet metal to concentrate on innovation and customer engagement, which are crucial for maintaining a competitive edge. By entrusting the technical aspects of CAD drafting to expert outsourcing partners, these manufacturers can redirect their resources towards enhancing product quality, exploring new market opportunities, and strengthening their brand presence.

In conclusion, outsourcing CAD drafting emerges not just as a cost-saving measure, but as a strategic decision that can drive long-term growth and success for manufacturers in these industries. It represents a smart alignment of resources, where the focus shifts from managing operational complexities to achieving business excellence and innovation.

Get reliable and accurate CAD Drafting specialists at affordable rates.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.