Outsourcing CAD engineering services makes a huge difference in manufacturing efficiency as it streamlines your design process, cuts down on mistakes and gets your product to market in no time. Outsourcing your CAD work also provides access to skilled experts, plus the latest tech and design automation tools. All of these come together to give you better products at lower costs.

info@truecadd.com

How Outsourcing CAD Engineering Enhances Manufacturing Efficiency

Table of Contents

- Why CAD engineering is critical for manufacturing efficiency

- How outsourcing CAD engineering enhances manufacturing processes

- Key benefits of outsourcing CAD services for manufacturing

- Common misconceptions and realities of outsourcing CAD services

- Choosing the right CAD engineering partner: Key considerations

- Future of manufacturing: The role of outsourced CAD engineering

- FAQs on outsourcing CAD engineering

- Wrapping Up

Bottlenecks in the design process can really slow you down, putting manufacturing behind schedule and way over budget. But one way to get around this is to partner with a specialized company for outsourcing CAD engineering. Working with specialized mechanical CAD drafting services can give you access to a team of experienced engineers and technology. Often it is a lot cheaper than trying to do it all in-house.

By letting go of most of that design work to the outside team, you’re freeing up your internal resources to focus on what they do best and that in turn leads to a faster time to market, lower production costs and all around a more efficient manufacturing process thanks to the proven CAD outsourcing benefits.

India’s apparel manufacturing industry found in a research that CAD adoption led to a 86.2% variance in business performance improvement. Cost effectiveness (r = .896), production efficiency (r = .882) and competitive capability (r = .895) were positively correlated. Source:Researchgate.Net

Why CAD engineering is critical for manufacturing efficiency

CAD makes a huge difference in efficiency by offering you accurate 3D CAD modeling for manufacturing. This lets you do quick design tweaks and even test out manufacturing processes in a virtual setting so you can optimize them.

Doing CAD digital prototyping frees you from expensive physical models and you can catch mistakes way early on, which means a lot less waste and rework and a shorter time getting the product to market. It also helps keep costs down and helps you improve product design efficiency.

CAD data perfectly integrates with CAM systems making it a smooth transition from design all the way to production and letting you automate on the shop floor. This results in fewer chances for manual error and it gives you a lot more confidence in your end results.

How outsourcing CAD engineering enhances manufacturing processes

Outsourcing CAD engineering is a strategic move that can actually change the way you manufacture. Here are a few ways in which it can really transform your manufacturing process:

- Quicker product development: Companies that specialize in 3D CAD drawings for product design and development can do rapid design tweaks which means you can get your CAD project finished faster. By teaming up with expert CAD firms, can skip the whole process of building up your own CAD team from scratch and that means getting your product to market sooner.

- Access to the latest tech and expertise: Mechanical CAD design outsourcing lets you tap into the latest design software and the kind of expertise you’d need to keep up with the competition. That keeps you ahead of the game when it comes to innovation, so you can use all the advanced design techniques you need to make your products really perform.

- Better communication and project management: Companies that offer CAD engineering services already have their systems in place for communication and project management. So you can be sure that your streamlined manufacturing processes will run smoothly without misunderstandings and delays.

- Flexibility and the ability to scale up or down: Outsourcing CAD engineering lets you scale up your resources when you need to and scale back again when you don’t. So you can get the extra help you need during busy periods and then dial it back down when the pressure’s off.

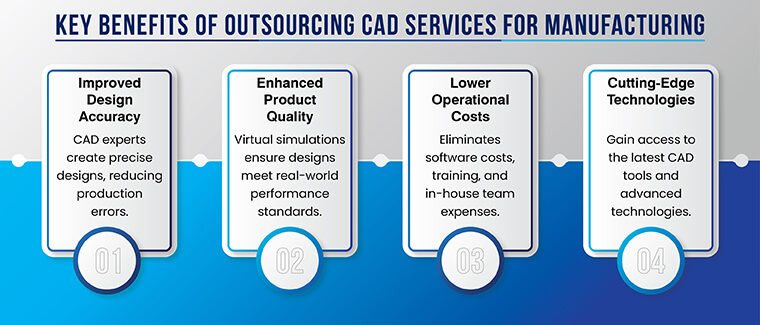

Key benefits of outsourcing CAD services for manufacturing

Outsourcing CAD services is often a tactical decision that can have a big impact on production and the bottom line. It lets manufacturers save their budgets with cost effective CAD solutions.

Here are some of the key advantages of CAD outsourcing:

Design automation for streamlined production

Working with an outside CAD engineering expert allows manufacturers to access professional design automation tools that can help streamline production. Specialized CAD outsourcing companies are experts in using software like SolidWorks and DriveWorks to accelerate your design process though automation technology. They can create standardized design templates and workflows that cut down on manual labor and mistakes.

Manufacturers end up with faster design cycles and shorter lead times because design automation takes care of all the repetitive tasks. This means that as soon as the design is done, manufacturing can get going and production schedules can be optimized. Thus you get less downtime and more productivity.

Take the next step toward optimized manufacturing.

Contact our experts »Metal Doors & Frame Design Customization using DriveWorks

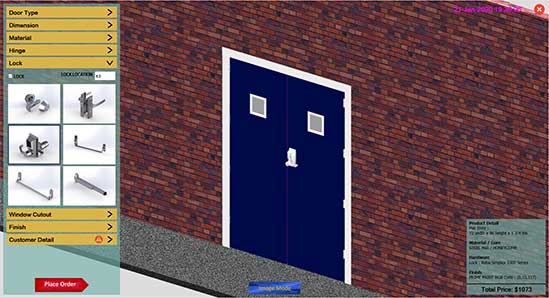

A U.S. based hollow metal doors and frames manufacturer was facing difficulties with fragmented design data, no clear process for custom orders and too much repetitive drafting work which was causing delays, errors and slow customer response times.

TrueCADD developed a DriveWorks based door configurator that could generate 3D CAD models and manufacturing drawings from custom design input. We automated all the variable parameters and as a result they were able to get their shop drawings out to customers a lot faster.

The end results were:

- 70% reduction in design cycle time

- Faster responses to customer enquiries

- Higher consistency and fewer errors in production documents

Online Configurator for Metal Door

Online Configurator for Metal Door

3D Door Components Customization

3D Door Components Customization

Get design automation to reduce design cycle time by 70%.

Implement now »Better product design and faster prototyping

An outsourcing CAD engineering company can have a really positive impact on the whole product design and prototyping process. Companies that have an inhouse engineering team already benefit from getting a bigger talent and specialist pool through mechanical design outsourcing but without having to go through the hassle of recruitment and training.

Getting access to CAD drafting services for manufacturing means you can get high quality 3D models from that wider talent pool. This makes it a lot easier for design and manufacturing teams to talk to each other and make sure they’re both on the same page when it comes to specs and requirements.

By using advanced industrial design CAD software, these firms can make virtual prototypes which they use to test out design ideas in a digital space and not with actual physical prototypes. And that means big cost and time savings during product development.

The faster the iteration process, the quicker you’ll get the design finalized and the sooner you’ll have a prototype ready.

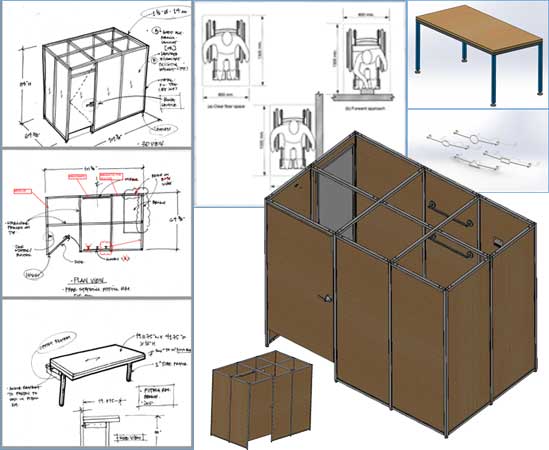

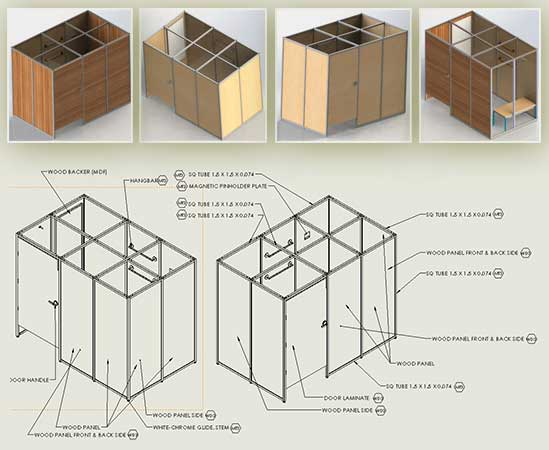

Detailed CAD Drawings & 3D Models for Retail Furniture Manufacturer

A UK based retail furniture designer and manufacturer had only hand scrawled concept sketches. What they needed was precise 2D CAD drawings and 3D models that included all the manufacturing details right down to the shop drawings.

TrueCADD took those rough sketches and turned them into detailed 2D CAD drawings and accurate 3D models using SolidWorks, complete with all the manufacturing specs and ready to go straight into production.

The outcome was:

- Faster production planning

- Reliable 3D visualization for client approval

- Less chance of errors and a better manufacturing readiness

Concept Drawings to CAD Detail Design

Concept Drawings to CAD Detail Design

3D Models and Manufacturing Drawings

3D Models and Manufacturing Drawings

Simulation driven design for reduced testing costs

Simulation driven design lets you break free from the limitations of physical prototypes. With the right CAD software, you can have a detailed virtual model & then put it through its paces like stress, temperature changes, and vibrations all from your controlled digital environment.

This is where potential design flaws can be rooted out before we even start building the first physical prototype. For instance, when designing a turbine blade, we can use simulation to see how it will handle scorching heat & a fast spinning centrifuge. That helps us spot where it’s most likely to crack or break down.

By avoiding costly, time consuming physical testing and being able to refine repeatedly, we’re able to create products that are more efficient, more durable and safer. All this because you can try different materials, shapes & loads in the CAD environment.

Common misconceptions and realities of outsourcing CAD services

Lots of manufacturers still have misconceptions and wrong ideas about outsourcing CAD work, but in reality these supposed downsides are just myths.

Let’s discuss and dispel a few of these common myths:

Myth 1: Outsourced CAD work is of inferior quality.

Reality: The fact is high quality CAD outsourcing firms have experienced engineers and designers on hand who are experts in industry standard software and keep up with all the latest design codes. They also have all the right project management tools and communication channels in place to make sure your design gets done right and on time.

Myth 2: Outsourcing leads to loss of control over the project.

Reality: Actually, successful outsourcing is all about cooperation. With the right partner, you get regular updates on your project, two way communication and collaborative tools that let you make changes in real time. That means you have every bit as much control over your project as you would if you were doing it all inhouse. But with the added benefit of tapping into a pool of specialist expertise.

Myth 3: Outsourcing is only suitable for large scale projects.

Reality: While it’s true that big corporations often use outsourcing, its benefits apply just as much to smaller firms. Whether you need to design a single part or a whole assembly, CAD outsourcing gives you access to best designers and software without eating into your budget. So it’s a viable option for all kinds of projects, small or large.

Myth 4: Intellectual property (IP) security is compromised when outsourcing.

Reality: Professional CAD outsourcing firms know how important it is to keep client data safe and secure. That’s why they use non-disclosure agreements (NDAs) as standard. They won’t let your IP out of their sight, even if they’re working on other projects at the same time. And they have secure transfer protocols and access controls in place to minimize the risk of any kind of breach.

Choosing the right CAD engineering partner: Key considerations

Picking the right CAD engineering partner when you outsource 2D & 3D CAD drafting services is a big deal if you’re trying to get a team working smoothly with your manufacturing workflow. If you get it wrong you will face delays, communication problems and impacts on the quality of your project.

Key factors to think about when making your decision:

Reputation and experience

Evaluate the firm’s track record. Look for proper case studies that show how they’ve done things for people in your industry before. And have a read through those customer testimonials and online reviews. They will give you a good idea of how reliable they are, if they can hit deadlines and how well they can solve problems.

CAD software expertise

Check that your potential partner has skilled professionals who know their way around the CAD software your project requires like SolidWorks, AutoCAD or Autodesk Inventor. They need to have a deep understanding of how CAD engineering outsourcing for manufacturers work and all its fine details like advanced features and customization options.

Communication and project management

Good communication is key to getting people working together. Have a look at how the team likes to communicate. Are they the kind of people who keep you in the loop all the time? Do they have a clear workflow in place and do they use project management tools and version control to make sure everything runs smoothly?

Data security and confidentiality

The kind of designs you produce in manufacturing often contain sensitive information that you don’t want getting out. So make sure you know the partner you choose is serious about keeping it all confidential. Check if their computer systems are locked down tight and if they up to speed with all the latest security regulations. A proper NDA is also vital to keep your trade secrets safe.

Future of manufacturing: The role of outsourced CAD engineering

The future of manufacturing is deeply connected to outsource CAD engineering and the impact that these companies are going to have is pretty big.

CAD design services for manufacturers are just about experts at making sure designs that get made can be printed in 3D as easily as possible, they cut down on materials needed and get products out the door faster. And to do all that, they use topology optimization and generative design software to get even more out of the benefits.

These CAD services companies are rushing to get AI into their workflow. They’re using machine learning to get generative design working for them, which lets the machines experiment with loads of different design ideas based on what the customer needs.

And then there is the data rich environment of smart factories that outsourced CAD companies are going to really benefit from. They can create digital twins of products and processes so you can run simulations and do analysis. This in turn lets you make better production planning, do better predictive maintenance and even make decisions on the fly.

FAQs on outsourcing CAD engineering

-

Outsourcing CAD engineering lets you tap into a team of skilled professionals, saving you money while still getting high quality designs and accelerating your production timelines.

-

Absolutely. Outsourcing eliminates the need to spend a fortune on software, extensive training and all the daily costs of maintaining a team, while delivering high quality designs that you need.

-

CAD teams specializing in outsourcing have spent years honing their skills in creating accurate designs, backed up with simulations. This adds up to a much higher quality product and fewer manufacturing errors.

-

Automation streamlines the design process by taking care of the repetitive bits. This speeds everything up and means you can make changes on the fly making your whole process way more efficient.

-

When picking a CAD partner, look for someone with lots of experience in your industry, all the right software skills and robust commas and project management systems in place. These are the things that mean a partnership will actually work.

Wrapping Up

Outsourcing CAD engineering is not a bonus, it’s essential if you want to stay ahead of the game. By working with an external team of experts and using tools like design automation and simulation driven design, your business can cut its lead times down to size, lower costs and create products that really shine.

CAD/CAM outsourcing is a key way to set your internal team free so they can focus on the things that really matter and drive innovation that fuels growth. Outsourcing CAD engineering is a gamechanger today and the key to making your manufacturing dreams come true.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.