Effective sharing of 3D models for sheet metal assemblies enhances collaboration, accuracy, and manufacturing efficiency. Parametric CAD tools and the right file formats ensure seamless, secure and collaborative information exchange and data integrity.

info@truecadd.com

5 Ways to Share 3D Models for Sheet Metal Assemblies

Table of Contents

- 5 Ways to Share 3D Models for Sheet Metal Assemblies

- Essential Tools and Software for 3D Sheet Metal Design Modeling

- Prepare and Optimize 3D Sheet Metal Models for Sharing

- Choose the Right File Format for Sheet Metal Assemblies

- Secure CAD File Sharing for Sheet Metal Assembly Models

- Collaborative Workflows and Revision Management in Sheet Metal CAD Projects

Sharing 3D models for sheet metal assemblies without design data loss is crucial for effective collaboration, improving accuracy, and facilitating efficient manufacturing. It helps reduce errors by aligning the work of design, engineering, and manufacturing teams.

Additionally, using a 3D model for manufacturing sheet metal parts helps in precise design validation, detailed production planning, and comprehensive documentation. It makes updates easy and helps maintaining accuracy throughout the sheet metal fabrication process.

However, issues like large assembly files and CAD software compatibility hamper seamless data sharing. Other than this, intellectual property protection and data security are major concerns, as companies must safeguard their designs when sharing with sheet metal drafting expert. This necessitates the need to be compliant with international design standards and to have robust tools with clear communication.

5 Ways to Share 3D Models for Sheet Metal Assemblies

Maintaining design intelligence during the sharing of models across teams is absolutely necessary. The effective sharing of 3D sheet metal assembly models is enabled by a combination of CAD software, modern technology, and best practices. The right tools and processes enhance collaboration, accuracy, and productivity in the sharing process.

Let’s look at some key ingredients that make for efficient assembly file sharing.

1. Essential Tools and Software for 3D Sheet Metal Design Modeling

Efficient 3D CAD modeling for sheet metal design relies on robust software tools like AutoCAD, SolidWorks, and Autodesk Inventor.

AutoCAD offers powerful drafting and detailing capabilities that are essential for creating precise flat patterns and detailed drawings. It supports the DWG file format, ensuring compatibility with various tools.

SolidWorks is known for its intuitive interface and specialized sheet metal tools, such as automatic bend allowance calculation and unfolding features to streamline designing. Its sheet metal model assembly management capabilities offer powerful visualization to reduce errors.

Autodesk Inventor excels in its parametric design approach, allowing for easy modifications and updates to the design. It includes advanced sheet metal functionalities like bend correction, automated flat pattern creation, and efficient management of large assemblies.

When choosing CAD software for sheet metal design, key considerations include compatibility with other design and manufacturing tools, ease of use, and the availability of specialized features.

Compatibility ensures seamless integration with existing workflows and systems, minimizing data loss during file transfers. Ease of use is critical for reducing the learning curve and increasing productivity.

Specialized features, such as automatic unfolding and bend correction, are essential for addressing the unique challenges of sheet metal design, ensuring accurate and manufacturable designs. Ultimately, the right CAD software enhances sheet metal assembly collaboration, precision, and efficiency in the design and manufacturing of sheet metal assemblies.

Start improving your 3D model sharing process.

Contact us today →2. Prepare and Optimize 3D Sheet Metal Models for Sharing

3D CAD tools like SolidWorks or Inventor offer multiple benefits for sheet metal product design drafting. Preparing and optimizing the 3D assembly CAD models in certain ways promotes ease in file sharing, reduces errors, and ensures that the integrity and functionality of the design are maintained throughout the process.

Simplification Techniques

Simplifying complex assemblies is essential for reducing file sizes and improving the manageability of models without compromising design integrity.

Deleting extra information: One effective technique is removing unnecessary details that do not impact the overall function or fit of the parts. This can include small fillets, chamfers, or intricate patterns that are not critical to the assembly.

Using simplistic icons: Using simplified representations for standard parts, such as bolts, nuts, and washers, can also help. Replacing detailed models with basic geometric shapes reduces the file size.

Disfeaturing: Disfeaturing is another crucial technique, where nonessential features are stripped from the model. This includes removing internal components that are not visible or necessary for the external assembly review.

Leveraging LOD settings: Level of detail (LOD) settings can help create multiple versions of a model at different levels of complexity, allowing stakeholders to choose the appropriate level for their needs. Creating lightweight formats, such as JT or 3D PDF, can further reduce file size while retaining essential geometric information and annotations.

Enhancing Documentation

Detailed documentation and annotations play a critical role in ensuring clear communication across teams, especially for assemblies with multiple parts and complex configurations.

Views: Comprehensive assembly instructions should accompany the models, including exploded views that clearly show how components fit together.

Detailed annotations: Detailed annotations of the models, such as dimensions, material specifications, and tolerances, are essential for ensuring that all stakeholders understand the critical aspects of the design.

Adding BOM: Including a bill of materials (BOM) with each assembly model helps identify and manage parts efficiently. The BOM should list all components, their quantities, and reference numbers, providing a clear inventory for manufacturing and assembly teams. Cross-referencing annotations with the BOM ensures that each part is accounted for and correctly identified.

Adding interactivity: Interactive documents can enhance understanding and usability. For example, using tools that allow users to rotate, zoom, and interact with the 3D model within the documentation can provide better insights into the assembly process.

Maintaining revision: Providing a clear revision history and change logs ensures that all stakeholders are aware of updates and modifications, reducing the risk of errors caused by outdated information.

Reduce errors with an expert validating your documents for sheet metal models.

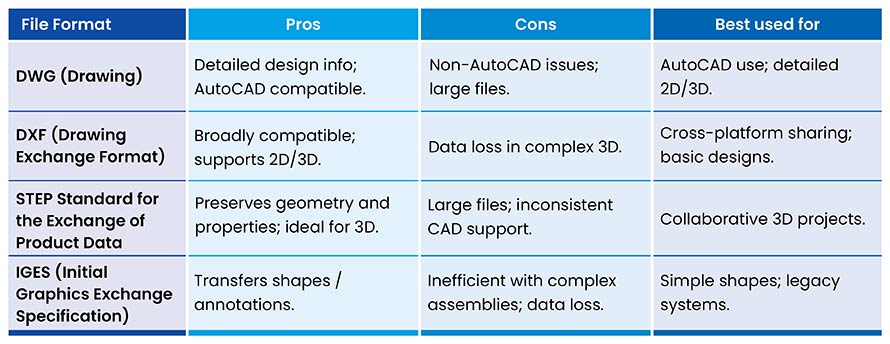

Contact us today →3. Choose the Right File Format for Sheet Metal Assemblies

Selecting the right file format for sheet metal assemblies is crucial for ensuring compatibility, preserving design details, and facilitating efficient collaboration. Here’s an overview of commonly used file formats:

Format Selection Criteria

When choosing the optimal file format, consider the following criteria:

- Collaboration Needs: For projects requiring extensive collaboration across different platforms, STEP is recommended due to its robust support for detailed 3D assemblies.

- Software Compatibility: DWG is ideal for teams using AutoCAD, while DXF offers broad compatibility for various CAD systems.

- Complexity of Assembly: For highly detailed and complex assemblies, STEP provides the most comprehensive data exchange. For simpler designs or legacy systems, IGES can be sufficient.

Selecting the right file format enhances workflow efficiency, maintains design integrity, and ensures smooth communication between stakeholders.

4. Secure CAD File Sharing for Sheet Metal Assembly Models

Secure sharing of sheet metal assembly files is essential for effective collaboration and protecting sensitive design data. Cloud-based solutions offer robust options for securely sharing complex sheet metal models and assemblies.

Cloud-Based Solutions for Sheet Metal Designs

Cloud-based CAD platforms like Autodesk Fusion 360, Onshape, and PTC’s Creo offer secure environments for sharing and collaborating on sheet metal designs.

Autodesk Fusion 360 integrates design, engineering, and manufacturing into a single platform, allowing teams to collaborate in real time, regardless of location.

Onshape provides a comprehensive set of CAD tools directly in the browser, enabling easy sharing and collaboration with robust version control and access management features.

PTC Creo offers cloud capabilities that streamline the sharing of complex assemblies while maintaining data integrity.

These platforms support secure file storage, version tracking, and real-time collaboration, ensuring that all stakeholders have access to the most up-to-date models.

Data Security Practices

To ensure the integrity and security of shared CAD models, implementing best practices for data security is crucial.

- Access Controls: Limit access to sensitive data by implementing role-based access controls (RBAC). This ensures that only authorized users can view, edit, or share the CAD models.

- Encryption: Use encryption for both data at rest and in transit. Cloud-based platforms typically provide built-in encryption, but it’s essential to verify that this feature is enabled.

- Regular Backups: Regularly back up all CAD files to prevent data loss due to accidental deletion or corruption. Cloud platforms often include automatic backup features, but it’s good practice to maintain local backups as well.

- Intellectual Property Protection: Utilize digital rights management (DRM) tools to protect intellectual property. These tools can restrict the ability to copy, print, or modify the shared files without proper authorization.

- Audit Trails: Maintain detailed audit logs to monitor access and changes to CAD files. This helps in tracking unauthorized access or modifications, ensuring accountability.

By leveraging cloud-based CAD solutions and adhering to stringent data security practices, organizations can effectively share sheet metal assembly models while safeguarding their intellectual property and maintaining the integrity of their designs.

5. Collaborative Workflows and Revision Management in Sheet Metal CAD Projects

Tools and Techniques for Real-Time Collaboration

Effective real-time collaboration in sheet metal CAD projects requires robust tools like SolidWorks 3D EXPERIENCE. This platform supports synchronous work, allowing multiple users to work on the same model simultaneously. Features include real-time editing, commenting, and in-app chat for instant feedback and discussion.

Screen sharing and virtual meeting tools, such as Zoom or Microsoft Teams, are also invaluable for collaborative sessions, allowing team members to discuss design issues and solutions in real time.

Effective Revision Management

Effective revision management is crucial for consistency and accuracy in sheet metal CAD projects. Version control systems in platforms like PTC Creo and SolidWorks offer tools for tracking changes, ensuring the latest updates are always available while preserving previous iterations.

Naming conventions and documentation are essential, with each revision clearly identified and summarized. Branching and merging allow team members to work concurrently and integrate changes seamlessly. Automated notifications and revision histories keep stakeholders informed, preventing miscommunication and ensuring everyone works with the most current design.

By utilizing these tools and techniques, teams can enhance collaboration, streamline workflows, and maintain rigorous control over revisions, ensuring the successful management of sheet metal CAD projects.

Conclusion

Adopting specialized, secure, and streamlined practices for sharing sheet metal CAD models is crucial for achieving optimal project outcomes in the sheet metal industry.

Secure data management practices, such as encryption and role-based access controls, protect sensitive design information and intellectual property, ensuring that only authorized personnel can access critical data.

Simplifying complex models and enhancing documentation are essential strategies that improve clarity and reduce assembly model filesizes without compromising design integrity.

Detailed annotations and comprehensive documentation ensure that all stakeholders understand the design specifications, facilitating smooth collaboration and minimizing errors. These practices not only enhance collaboration and productivity but also ensure the security and integrity of shared models, ultimately driving innovation and success in the sheet metal fabrication industry.

Have nothing more than the right CAD tools to innovate your modeling sharing process

Contact us today →Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.