Design automation tools like SolidWorks and DriveWorks help in cutting costs by streamlining design processes, reducing material waste and making fabricators’ work a lot more accurate. By automating all those repetitive tasks and making it easier for teams to communicate with each other, these tools are really reducing labor costs and getting projects moving a lot faster.

info@truecadd.com

How Design Automation helps Metal Fabricators Reduce Manufacturing Costs

Table of Contents

- What is design automation in metal fabrication?

- Benefits of design automation for metal fabricators

- How design automation for fabricators reduce manufacturing costs

- Pain points for metal fabricators when adopting customization

- Overcoming common challenges in implementing design automation for metal fabricators

- The future of design automation in metal fabrication

- FAQs on design automation for metal fabrication

- Conclusion

Design automation for metal fabricators gives them a real edge in the market where manufacturing costs are always going up. By automating the design process, metal fabricators can cut out a lot of errors and make their workflows smoother. And that efficiency trickles down to faster turnaround times and getting the most out of every bit of material, which lead to cost savings.

The benefits of design automation in metal fabrication powered by SolidWorks and DriveWorks go beyond saving cash. They let fabricators try out different design ideas and push the boundaries of innovation to make better quality products. And because these tools take care of the routine stuff, fabricators can spend their time on the complex, high value projects that drive business forward.

If you want to stay competitive in the metal manufacturing industry, proper metal fabrication automation will help you design faster, reduce waste and improve your bottom line.

What is design automation in metal fabrication?

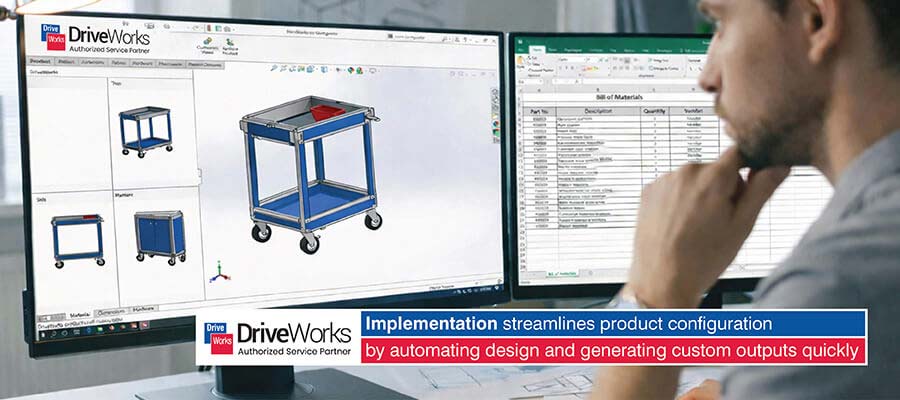

Design automation uses advanced software to automate repetitive design tasks during the manufacturing process. In place of manual input, with automation, fabricators can now create designs at high speed that can be directly fed into production without issues. You’ll find tools like SolidWorks and DriveWorks, automation software that integrates with SolidWorks, are used most in the industry.

With SolidWorks, engineers can build 3D models of metal parts with precision. DriveWorks design automation for metal fabrication helps you to automate the process of creating one off products based on pretty much any design rule. And the combination is extremely helpful in terms of speed and consistency across projects.

Metal fabricators can overhaul their workflows from top to bottom using these tools, making their manufacturing processes faster, more accurate and much more consistent.

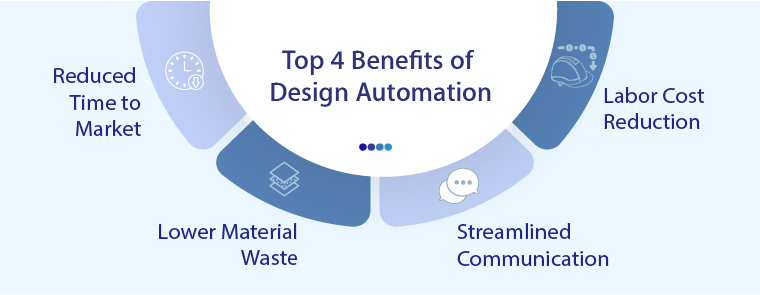

Benefits of design automation for metal fabricators

Design automation for metal fabrication is helpful for fabricators, transforming their workflow and improving their productivity.

Here are a few of the main benefits to look out for:

Reduced time to market

The first thing that you notice when you use design automation is how big of a timesaver it can be. With tools like SolidWorks and DriveWorks, metal fabricators can make changes on the fly, which translates into reducing a major unnecessary part of the production cycle.

For instance, DriveWorks eliminates repetitive design tasks by automatically creating lots of different design variations with just a few key inputs. That means saving a lot of time on custom fabrication projects and reducing project lead times to nothing. Which is exactly what you want when you’re working to tight deadlines.

Lower material waste

In metal fabrication, precision is everything. Anything less than perfect can mean all kinds of costly mistakes. But with automated CAD for metal fabrication with tools like SolidWorks, you can reduce waste right down to the bare minimum. Efficient designs are made, and only the exact right amount of material is used every time.

And then there’s DriveWorks making sure that every single custom product variation comes out right and that it’s made with the minimum material needed. By reducing manufacturing costs in metal fabrication through cutting down waste, fabricators save cash and help keep production greener.

Streamlined communication between design and production teams

Problems in communication between design and production teams can lead to errors and delays and these cost a lot to fix. To address this challenge, design automation tools like SolidWorks link the design data straight into the production process. This means that both teams are working from the same platform and get updates in real time so everyone’s on the same page and errors decrease.

By integrating DriveWorks into this process, you can actually automate the whole process of taking a design and turning it into a product that can be manufactured. DriveWorks will automatically create the necessary data in real time, like CAD models and drawings, to make sure that the design gets turned into the required product.

This streamlined process makes a big difference. It minimizes mistakes, cuts down on rework and gets products to market a lot faster. Also, it results in a huge improvement in metal fabrication efficiency and profitability.

Labor cost reduction and skill gap bridging

As manufacturing gets complicated, it needs more skilled labor. In such a situation, design automation tools like DriveWorks make a big difference by simplifying the fabrication process. This makes it possible for people without advanced CAD skills to do design tasks, providing the most practical way for reducing labor costs with design automation.

SolidWorks also has an interface that is intuitive and makes on boarding of employees easy. When combined with DriveWorks, you get a system ready to deploy advanced manufacturing techniques without needing extensive training of staff. So, fabricators can make complex products without needing a team of super skilled experts.

How design automation for fabricators reduce manufacturing costs

Design automation brings real savings by simplifying the fabrication process and cutting down on the time it takes to do tasks manually. Here are the ways metal fabricators can use automation to give their bottom line a boost.

Automation of repetitive design tasks

Now it is easier for metal fabricators to streamline repetitive tasks with SolidWorks design automation tools like DriveWorks which lets them automate all the tasks that used to take much longer to do by hand. Tasks like making shop drawings through SolidWorks drafting in metal product design, arranging parts to get the most out of your materials and setting up your CNC machines can now be done with minimum effort.

For example, if you produce a lot of standard parts like brackets or frames, you can store the designs in a DriveWorks database, and they can be produced with barely any manual input needed.

By letting automation take care of the routine work, you can really cut down on lead times, get costs down and free up your designers to tackle more complicated jobs. Parametric CAD design saves you a ton of time when you need to tweak things like dimensions or material thickness because you don’t have to draw the whole thing over again.

And automation also lets you generate the exact CNC code you need directly from your design files, which keeps the workflow consistent and reduces errors.

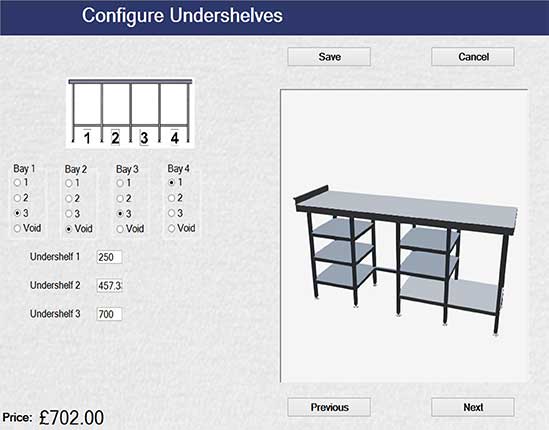

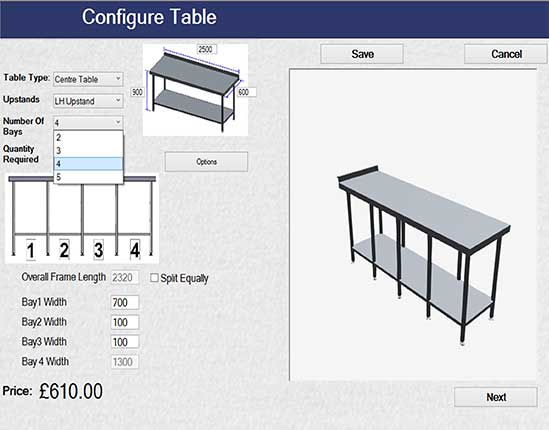

DriveWorks Table Configurator for Stainless Steel Furniture Manufacturer in UK

A UK based furniture maker making stainless steel tables for restaurants and pubs was having difficulties with long lead times and custom orders. There were varying requirements with floor space, material and design and their manual CAD process was slow and error prone.

TrueCADD built them an online configurator using DriveWorks that integrated with CAD to let the client design and order their table in minutes. They could specify the dimensions, frame and materials they needed and the system would come back with 3D models, manufacturing drawings and a quote, all in mins.

The end results were:

- Cut design turnaround time

- Automated 3D CAD modeling and manufacturing drawings

- Improved responsiveness and streamlined production workflow

Table Undershelf Configuration

Table Undershelf Configuration

CAD Configurator for Stainless steel table

CAD Configurator for Stainless steel table

Eliminate repetitive tasks and reduce total fabrication costs.

Contact our automation experts »Cost savings through improved accuracy

Integrating design automation software like DriveWorks into your SolidWorks workflow slashes costs through a big reduction in mistakes. By capturing your design rules and logic straight into SolidWorks, DriveWorks lets you create error-free manufacturing drawings and CNC files directly from sales configurations or design variations, which helps with cutting CNC machining costs.

When you use CAD software for metal fabrication efficiency, you avoid the expense of having to reenter data manually. Take the case of a sheet metal door maker, for example. By implementing a visual product configurator, the team can see real-time updates as every customer order is a new set of dimensions, materials and hardware needs.

Trying to translate that into shop floor ready deliverables annually is a recipe for disaster with dimensional errors, wastage and costly reworks.

What DriveWorks does is take the variables you put in and automatically generate the precise flat patterns, bend deductions and cut lists for you. This also helps you with material optimization in fabrication.

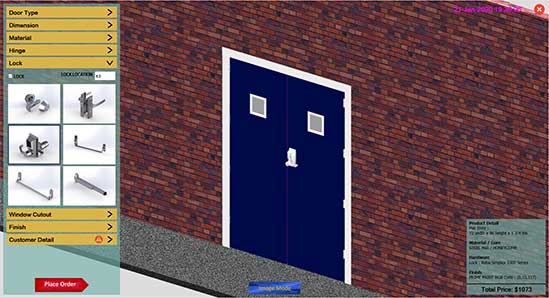

Door Configurator for Metal Doors and Frame Manufacturer

A US manufacturer of hollow metal doors and frames was struggling with transferring design data properly, custom order processes that were all over the place and just doing all the drafting manually over and over again. It was a slow and error-prone system that needed a serious overhaul.

TrueCADD created and deployed a custom metal product configurator using DriveWorks and SolidWorks. This allowed us to automate the creation of 3D CAD models and complete manufacturing drawings based on user input.

The final deliverables led to:

- 70% reduction in design cycle time

- Manufacturing ready CAD drawings and models

- Ability to respond to custom orders quickly

Online Configurator for Metal Door

Online Configurator for Metal Door

3D Door Components Customization

3D Door Components Customization

Optimized supply chain management

One of the ways that design automation can really make a difference for metal fabricators is by streamlining their supply chain management. With automated design systems like SolidWorks and DriveWorks, you get accurate material requirements for every project. With this, you can avoid all the extra inventory and waste that comes with it leaving you free to manage your resources efficiently.

DriveWorks also brings predictability to your production schedule with its manufacturing workflow automation. This means design cycles are faster, errors are fewer and you get the most out of your materials. And DriveWorks also does a great job of ensuring that design and manufacturing teams are working with the same up-to-date information. This gives you a supply chain that is way more agile and efficient.

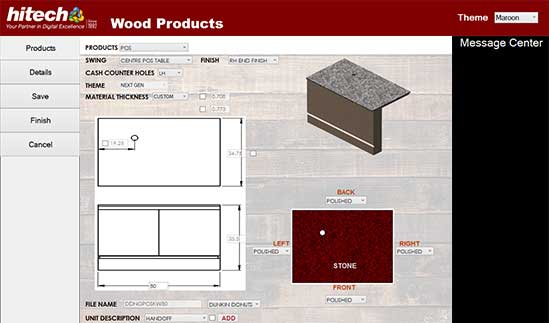

DriveWorks Design Automation for Metal & Wood Furniture Manufacturer

A metal and wood furniture manufacturer in the US was struggling with product variety, slow design cycles, tedious tasks and fragmented design data workflows. They needed custom furniture designs fast with accurate drawings and timely quotes for their customers.

TrueCADD created a bespoke DriveWorks based CAD configurator using the client’s 2D drawings. The end result was a user friendly front end that, generated accurate 3D CAD models, manufacturing drawings, documentation and quotes instantly all from user input.

This resulted in:

- Cutting down engineering lead time from 4–5 days to 1 day

- 70 times faster design cycle with improved quality

- Faster response to customer enquiries and quicker product delivery

DriveWorks Configurator for wood furniture products

DriveWorks Configurator for wood furniture products

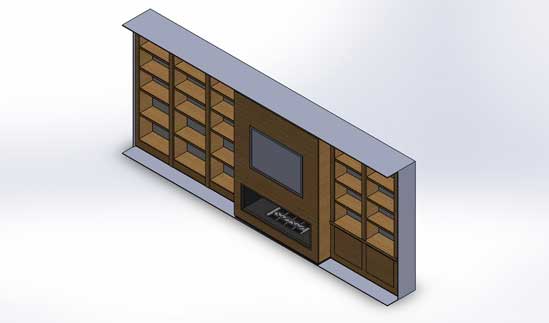

Automated CAD Design for Metal and Wooden Furniture

Automated CAD Design for Metal and Wooden Furniture

Simplify repetitive design tasks with sheet metal automation tools.

Get started today »Pain points for metal fabricators when adopting customization

Customization is a big ask in the modern manufacturing world but it’s a major issue for metal fabricators. Here are some of the common gripes they have about going down the customization route:

“Our design teams take forever to create drawings. And without updated drawings on the shop floor, project timelines keep getting pushed ahead. Even after investing several hours, design errors still remain.”

– Global Design Head, Retail Store Furniture Manufacturer, Europe.“My sales team is out in the field selling products that my shop floor can’t manufacture. Fixing this takes another week, and the customer is disappointed!”

– Project Engineer, Tank Manufacturer, USA.

“Every customer wants a different kitchen look. Calculating costs for customized products is crazy. We can’t share accurate quotes at such short notice!”

– Project Manager, Hydraulics Equipment Manufacturer, Australia.These cases show just how common problems like delayed design work, mixed up sales and production teams and the general problem of trying to price custom designs can be. These challenges regularly slow things down and affect profitability.

By automating the design to manufacturing workflow, DriveWorks bridges these operational gaps, transforming manual delays into a scalable, rules based competitive advantage.

Overcoming common challenges in implementing design automation for metal fabricators

Metal fabricators often hit roadblocks during implementation of design automation that need careful handling to overcome.

Initial investment costs

Design automation comes with a pretty hefty upfront price. You need software and advanced equipment. CAD systems like SolidWorks and DriveWorks can be expensive, plus the hardware to match. But for many fabrication shops, the long-term benefits (ROI) far outweigh the initial outlay.

Industrial automation for fabricators boosts efficiency, cuts down on waste and lowers labor costs. But before you make any investment in design automation to shorten engineering cycle time, take some time to think about what you really need and weigh up what you can save against what you’re spending upfront.

Learning curve and skill requirements

Stepping into new design automation tools can be tough. There’s a learning curve to consider and your employees are going to need some training of SolidWorks and DriveWorks. Both tools are really user-friendly, so it’s not as steep a learning curve as you might be worried about.

DriveWorks in particular is handy for letting users create customized interfaces, so even people without CAD experience can configure and manage products easily. And software vendors provide training resources to get you and your team up to speed.

The future of design automation in metal fabrication

The future of design automation in metal fabrication includes the use of AI, Machine learning & IoT. All these technologies are set to play a big part in making automation even slicker over the coming years.

The companies behind DriveWorks and SolidWorks are already getting the ball rolling for these advancements. Soon, AI powered automation tools will let fabricators avoid errors before they even happen, cutting costs in the process and making their systems even more efficient.

And on top of all that, Industry 4.0 has got a lot to offer. ‘Smart manufacturing’ systems let metal fabricators optimize their operations and get ahead in the competition.

FAQs on design automation for metal fabrication

-

Design automation is essentially how you get software like SolidWorks & DriveWorks to work together to make the design process easier & less time consuming in metal fabrication. By automating tasks you can speed up design time, get more accurate & cut waste, all of which adds up to saving even more cash.

-

It all depends on how you go about implementing automation, but typically you can expect to knock off anywhere around 20-30% of production costs by using SolidWorks & DriveWorks.

-

If you require top of the line CAD design tool then SolidWorks is the go. But if what your after is to automate the design of your custom products then DriveWorks is probably your safest bet. Both of these tools work well together & will set up a seamless workflow from design to production.

Conclusion

The benefits of design automation tools like SolidWorks and DriveWorks are pretty useful to your metal fabrication process. You can get to market a lot faster, cut down on material waste, lower your labor costs & generally improve overall production efficiency. By getting on board with these tools, fabricators can seriously cut down manufacturing costs and give themselves a much needed competitive edge.

As things keep changing in the industry, the role of automation in metal fabrication will only keep on growing, making it an absolute must for fabricators who want to stay ahead of the pack. Utilizing design automation tools like SolidWorks & DriveWorks and getting the most out of them can really help you drive down costs & take your operations to the next level.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.