Millwork shop drawings fail because of inadequate specification and detailing, measurement errors, missing specs, failure to include fabrication requirements and code violation. These can be avoided through structured communications, multi stage quality control checks on the drawings and using latest CAD tools that produce accurate fabrication ready drawings.

info@truecadd.com

5 Common Mistakes to Avoid in Millwork Shop Drawings

Table of Contents

- Millwork fabrication challenges due to mistakes in shop drawings

- 5 common millwork shop drawing mistakes and how to avoid them

- Proper communication to avoid common millwork drafting errors

- Millwork QA checklist: Preventing costly shop drawing errors

- How CAD software avoid millwork shop drawings errors

- FAQs on millwork shop drawings

- Conclusion

Millwork shop drawings are a bridge between design intent & fabrication. Shop drawing mistakes such as dimensional inaccuracies, missing specifications or unclear details affect all aspects of a project and cause material wastes, delays in installation and code violations.

Attention to detail and adherence to standards and documentation are required to prevent millwork shop drawing mistakes. Drafters can help reduce rework by identifying common errors and implementing prevention strategies to provide their fabrication teams with accurate information.

Some examples of these prevention strategies are quality control measures, standardized notation systems, communication protocols. And all these make shop drawings reliable road maps for fabrication.

In this article, we will discuss the 5 most common mistakes to avoid in your millwork shop drawings. Understanding them will help you in developing strategies to prevent them.

Millwork fabrication challenges due to mistakes in shop drawings

Millwork fabrication directly depends on correct dimensions, an understandable sequence of assemblies and all necessary material specifications in shop drawings. This is especially crucial for situations like millwork shop drawing for retail where accuracy directly impacts customer facing installations.

The following challenges occur in fabrication due to shop drawing errors:

- CNC machine failures and tool damage: Incorrect clearance between hardware items results in physical machine collision. Improper radii in shop drawings result in chatter marks or require entire part to be replaced.

- Material waste and production delays: Missing details in shop drawings results in fabricator having to either stop production, request additional information or assume what the designer intended.

- Veneer matching failure: Not including specific types of veneer matching or incorrect numbering of panels on shop drawings will result in irreparable sequencing errors.

- Accumulation of tolerance problems: Millwork measurement inaccuracies in finish thickness, and total joint tolerances, will cause doors to bind, drawers to scrape or fasteners to bulge through finished surfaces.

- Distortion of complex geometry: Use of incorrect algorithms to flatten curved parts into flat cutting patterns will result in faceting, stresses in seams or inability to properly assemble parts.

- Project delays and budget overruns: Challenges trickle down the project schedule and delay subsequent trades and negatively impact profitability due to material waste and labor inefficiencies.

Get shop-ready clarity with expertly crafted 2D submittal plans.

Contact Our Millwork Drafting Experts »5 common millwork shop drawing mistakes and how to avoid them

Following are some of the most frequent millwork shop drawing errors and how to avoid making them. The potential consequences of each error impact everything from fabrication accuracy to overall project success, so you should be mindful of these when developing your drawings. Understanding these will also help you better avail the benefits of outsourcing millwork shop drawings for scaling up your projects?

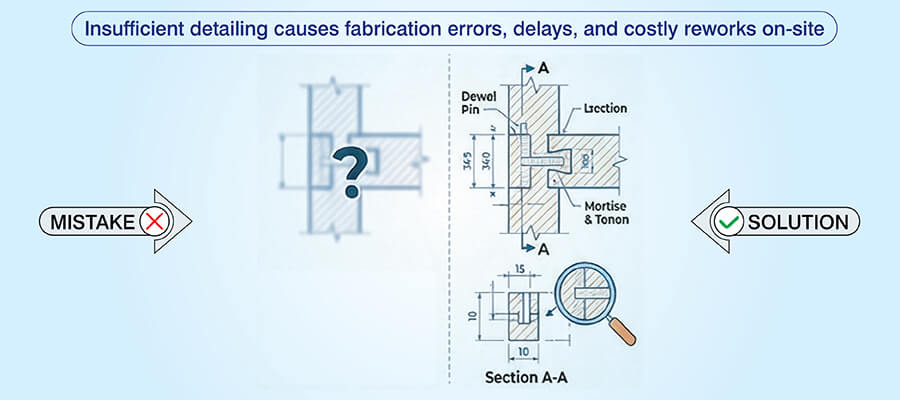

1. Incomplete component detailing leads to fabrication errors

Vague or incomplete detailing of the individual millwork components allows the fabricator to interpret the information in a way that will require guesswork. When the joinery documentation is unclear as to how to connect components, what joint tolerances apply or the sequence to assemble the components, woodworkers cannot determine how to properly perform the operation.

And when manufacturers make hardware placement errors based on ambiguous hardware placement locations or missing dimensional references in the shop drawings, the installer cannot align the hardware properly. Finish details such as edge treatment, profile specifications and transition conditions that are omitted create an inconsistency in appearance between components that are related.

How to avoid incomplete detailing in shop drawings:

Provide separate detail sheets for complex conditions having multiple views of 3D intersection points. Provide the assembly sequence using numbered steps and use the same symbol set throughout the drawing set. Document the section cuts through the complicated assemblies indicating the internal construction methods and fasteners used to construct the assembly.

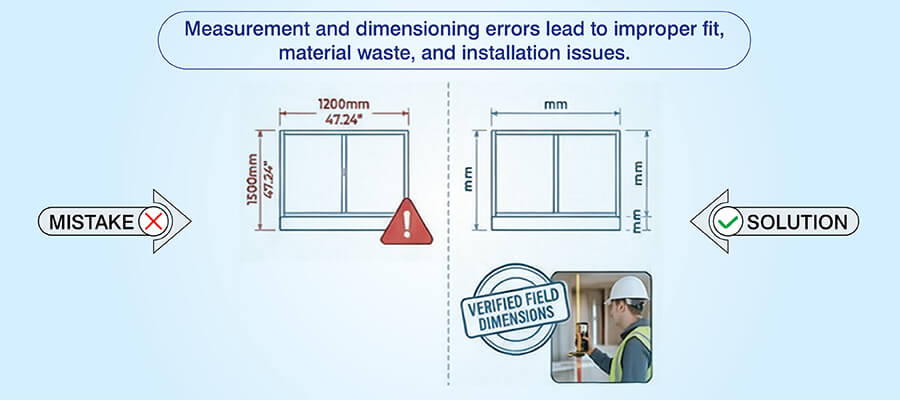

2. Measurement and dimensioning errors that cause fit issues

Millwork measurement inaccuracies are the most expensive errors and will directly affect component fit, the success of an installation and the efficiency of using the materials.

Measurement errors in millwork shop drawings, due to inconsistent dimensional references, overall dimensions being omitted or differing from view to view, create confusion among fabricators and cabinet makers and increases the possibility of creating incorrectly sized parts in woodworking shops.

Errors due to dimensional inconsistencies result from the failure of establishing clear datum reference locations, mixing imperial and metric units and failing to provide critical spacing dimensions between adjacent parts. Also tolerance documentation is necessary for parts requiring precise fit such as drawer fronts, door panels and countertop splices.

How to avoid dimensional errors:

Verify field conditions prior to finalizing the dimensions. Use a consistent unit system throughout the entire drawing set and detail what dimensional variations are acceptable for different types of parts. Ensure that dimensional chains are closed by confirming that the overall dimensions agree with the sum of the individual part dimensions and specify dimensional hierarchies with witness lines.

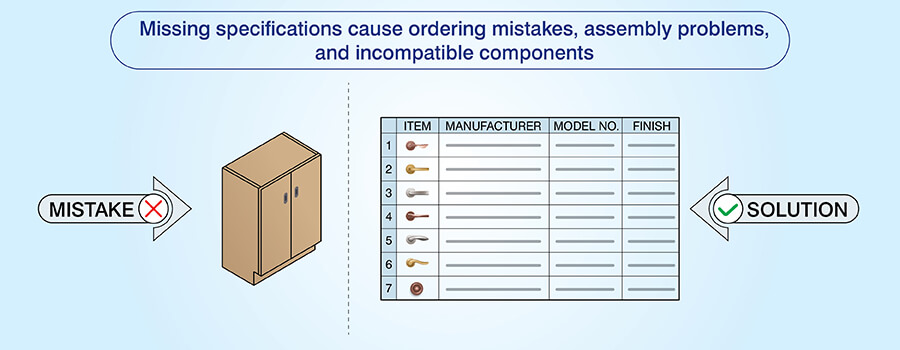

3. Missing or incorrect material and hardware specifications

Incorrect specifications regarding the type of wood being used, what the grade requirements are and missing moisture requirements will result in suppliers delivering you products that won’t perform the way you need them to.

There are many common millwork drafting errors that lead to these problems with material specs. They can occur from omitting what type of edge banding is required or failing to specify the type of substrate material required for painted vs. stained finishes.

Hardware specs must have the manufacturer’s name, model number and finish details plus installation instructions. Using generic hardware symbols will ultimately result in the product not functioning the way you require it to.

How to avoid incorrect material or hardware specifications:

Detail your specification callouts with the necessary product data sheet references & manufacturer specs and then create a centralized specification schedule or legend within your millwork drawings that includes all of your material & hardware information in one location. Double check your specs against the supplier data to ensure that the product is available and also match hardware locations to any enlarged detail views you have.

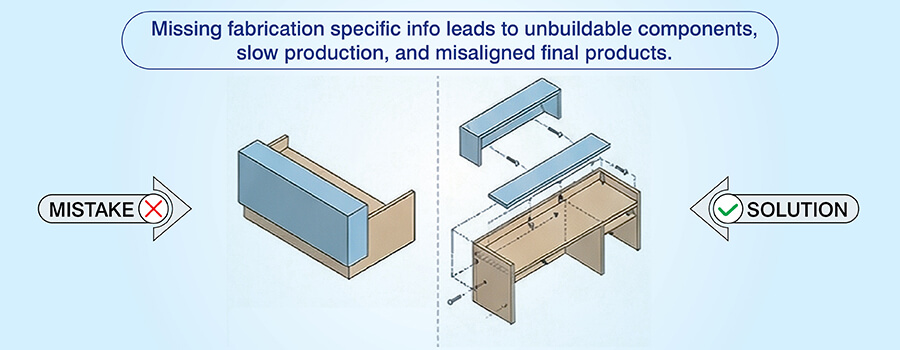

4. Failure to incorporate fabrication specific information

Shop drawings should be viewed as a set of clear instructions for the fabricator to follow and not just documents with correct dimensions. Without these instructions the fabricator has no idea how to assemble the various components, in what sequence or how to properly support the individual components as they are assembled.

Millwork detailing issues occur when there is an absence of information in the drawings that is important to the fabricator (e.g., type and size of fasteners to use, etc.) or how to properly assemble the entire product in a manner that makes sense.

How to avoid missing fabrication specific information:

Include step by step fabrication instructions in the drawings. Add notes relative to assembly sequencing and potential clashes. Document guidance relative to machining access. Specify the type and number of fasteners to use, spacing and installation procedure. Keep quality control checkpoints within the assembly sequences to identify potential errors prior to completion.

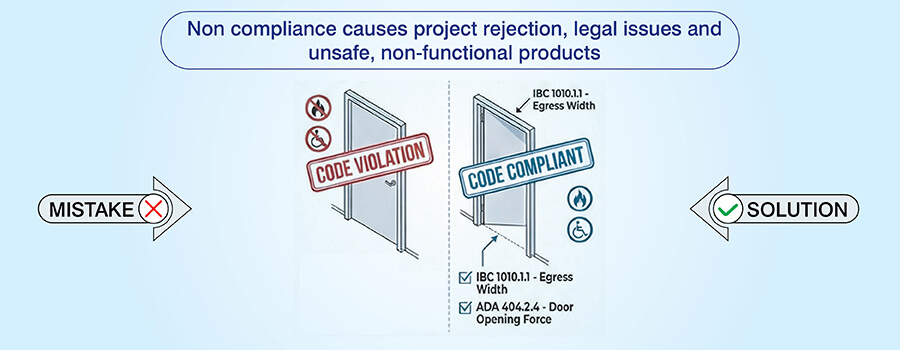

5. Noncompliance with codes and standards

If you lose focus on building code compliance in millwork projects, it could result in potential lawsuits and failed inspections causing you costly reworks. It’s crucial to ensure that building codes related to fire ratings, accessibility standards, structural load requirements or exit clearance standards are defined in your shop drawings and adhered to as much as possible.

The Architectural Woodwork Institute (AWI) provides industry wide millwork drawing standards and technical specifications to create common quality benchmarks.

Codes and regulations for buildings and millwork vary depending on location and each individual project. Therefore, it is necessary to perform research prior to developing your shop drawings and plans to verify compliance to applicable local codes and regulations.

Accessibility standards define minimums such as door handle height, operational force and floor space. Proper adherence to these elements can have a positive impact on your millwork design.

How to avoid noncompliance with standards:

Make sure to conduct a thorough review of building codes during the millwork drawing development phase. Show compliance with building codes clearly in your drawings with a direct reference to the specific section(s) of the code. Also, seek input from building officials early in the process and obtain their interpretation of any parts of the code that you are unclear about.

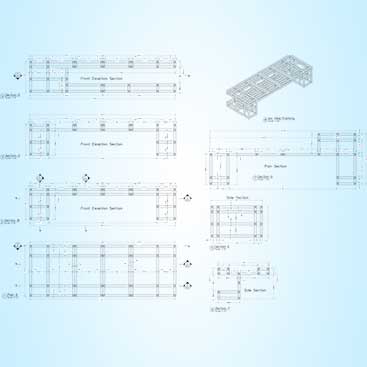

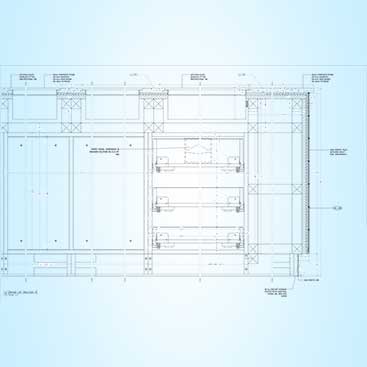

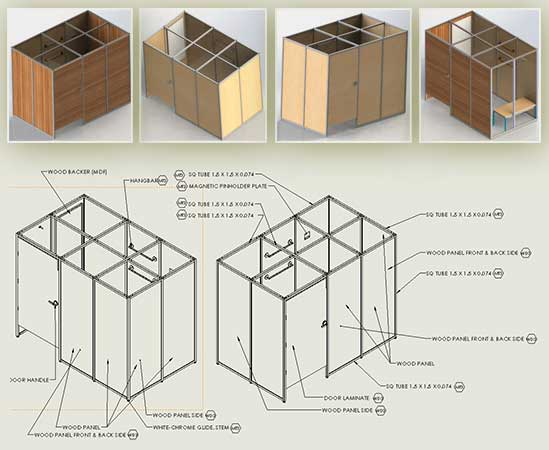

Detailed Shop Drawings for a Millwork Manufacturer, USA

A US based millwork manufacturer was struggling to convert architectural layouts into production ready shop drawings. They had inconsistent documentation, rework due to unclear details and long lead times that delayed fabrication and disrupted the manufacturing schedule.

TrueCADD created detailed CAD shop drawings, including elevations, sections and assembly guides from the architect’s layouts and hand sketches. We ensured precise joinery, material usage and installation sequences so fabrication and on site execution was streamlined.

The final deliverables were:

- Accurate fabrication drawings in less time

- Reduced installation errors and onsite adjustments

- Better coordination between design, manufacturing and installation teams

Manufacturing Shop Drawings

Manufacturing Shop Drawings

MillWork Shop Drawings

MillWork Shop Drawings

Proper communication to avoid common millwork drafting errors

Poor communication in drafting can occur when the drafter makes an assumption to meet a deadline instead of validating each detail with the RFI (Request for Information) process. Proper communication makes sure that there is no ambiguity and no possibility of fabrication error.

- Pre drafting constructability reviews determine conflicts between the architectural design intentions and physical limitations of materials and standard fabrication capabilities.

- Field verification protocols ensure specific tolerancing requirements and allows defining acceptable dimensional ranges and scribe allowance.

- Using standard annotation systems across the project makes everyone interpret symbols and fabrication instructions identically. Layer naming conventions properly communicating machining operations to the CNC software lets you avoid CAD errors in millwork.

- Cloud based collaboration platforms give the ability to have real time document access & coordinated communication to distributed team members.

- Structured revision cycles with formal review checkpoints and shared document control eliminates version confusion.

Get CNC-ready millwork drawings that cut fabrication time in half.

Request Files »Millwork QA checklist: Preventing costly shop drawing errors

Avoiding mistakes in shop drawings can be done through structured methods of verification around probable failure modes. A millwork QA checklist thus created serve as a prefabrication inspection to identify expensive, invisible errors.

- Dimension logic verification: Manually add all internal dimensions to verify that they match the total dimension. This will prevent CNC squaring failure.

- Finish thickness allowance: Ensure that a high gloss or polyester finish has material deducted at mating edges to prevent the finish from binding or chipping off.

- Hardware clearance check: Use section views to model internal hardware components to determine if there are any physical clashes between parts.

- Digital attribute audit: Perform initial nesting reports to ensure grain direction toggles and material code assignments correspond to specifications.

- Veneer sequencing documentation: Document veneer sequence to meet the requirement of continuous grain matching and scribe strip allowances.

How CAD software avoid millwork shop drawings errors

The use of modern CAD programs for millwork such as AutoCAD and Autodesk Inventor with parametric modeling, automated dimension chains and intelligent components help reduce the number of drafting errors.

Millwork drafting tools such as Cabinet Vision and Microvellum also provide industry specific libraries and automated nesting capabilities to help simplify the process of creating fabrication documentation.

CAD programs also include clash detection algorithms to identify interferences between components prior to fabrication to avoid costly problems with field conflicts.

Most CAD programs come equipped with version control to maintain a record of revisions to a project providing a way to recover previous versions and to view the development of the project through its various stages.

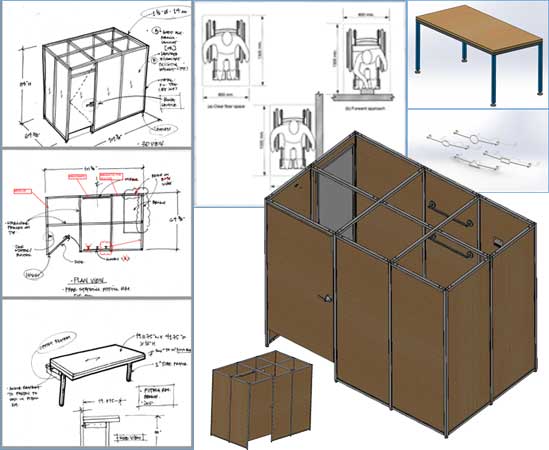

CAD Detailed Drawings & 3D Models for Retail Furniture, UK

A UK based retail furniture designer and manufacturer had hand drawn concept sketches and PDFs, with no dimensions and were struggling to convert these into manufacturing ready documents. Production was being delayed and errors were increasing.

TrueCADD produced 2D CAD drawings and 3D models with full manufacturing details, refined geometry and specifications from sketches and delivered a full drawing package with isometrics and BOMs to support production and assembly.

The final deliverables were:

- Manufacturing documents delivered on time

- Faster design to production

- Less errors and rework through standardized CAD output

3D Models and Manufacturing Drawings

3D Models and Manufacturing Drawings

Concept Drawings to CAD Detail Design

Concept Drawings to CAD Detail Design

The resulting product is a set of error free millwork shop drawings. The purpose of these drawings is to act as the link between the original design and the fabrication and therefore are critical to ensuring the success of your project and for you to remain competitive in the market.

FAQs on millwork shop drawings

-

It depends on how complicated your project is. You might be able to complete a simple piece of casework in just a few days, while more detailed custom millwork could take a few weeks to get right.

-

DWG and DXF are the standard CAD files, with PDF for documentation and approvals. You are also going to need CNC ready files in DXF or proprietary machine code.

-

Architectural drawings show the overall design. Shop drawings on the other hand give you the details that you need to fabricate, like exact dimensions, joinery, hardware and how the whole thing gets put together.

-

We use industry leading software including AutoCAD, Microvellum, Cabinet Vision, and SolidWorks. Which one we use depends on what is best for the specific joinery, custom cabinetry or bespoke furniture job at hand.

-

Absolutely. Our team is great at taking rough hand sketches, PDFs or designers ideas and turning them into shop drawings that are good to go straight to the floor. We raise formal RFIs to clear up any ambiguity or missing data before we start drawing.

-

We strictly follow rules and standards like AWI, AWMAC, NKBA, and the ADA guidelines. Before we hand a set of drawings over we run them against all those codes with our QA process so we know every dimension and clearance is right.

-

We create a detailed Bill of Materials (BoM) and hardware schedule straight from the CAD model. That way we get it right first time, keep track of every single veneer sheet and fastener and avoid over ordering. This helps keep the costs under control.

Conclusion

To reduce your millwork shop drawing mistakes it is necessary that your procedures for verifying your drawings be organized, your communication be clear and your techniques be correct throughout the entire drawing process.

Millwork projects have become increasingly complex with shorter deadlines; therefore, the pressure has increased to create less errors in each individual project and minimize overall error margins. It may also be beneficial to consider outsourcing to a professional millwork drafting service. These experts offer detailed quality control measures, the most CAD software and adhere to standard millwork drawing best practices.

Avoid costly fabrication errors with flawless millwork shop drawings.

Contact us »Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.