Accurate millwork material estimation is key to ensuring that the budget is realistic, and the job will achieve the required quality. Estimation includes the amount of materials needed, an estimate of the hours of labor to complete the job, including all overheads and the final cost for the work. Outsourcing to experts lets you improve your estimates throughout your project.

info@truecadd.com

Material Estimation Process for Millwork: A Contractor’s Guide

Table of Contents

Millwork businesses have to balance the creation of customized products within limited budgets and tight timelines. When there’s no economies of scale, inaccurate material estimates can severely affect projects and lead to costly waste and budget overruns.

The solution is to ensure that the material estimation for millwork is fully accurate. This requires detailed analysis and diligent calculation of millwork materials with complete estimate of the labor costs.

Using an accurate millwork estimation process improves profit margins due to optimized material use, better customer service through more accurate budgeting and reduced potential for project delays and inefficiencies in workflow.

What is millwork and why is accurate material estimation important?

Millwork encompasses every kind of custom, made-to-order woodwork and architectural elements. This includes cabinets, moldings, trim and others. Accurate material estimating is crucial for a number of reasons:

- Proper budgeting: Accurate estimates zero in on your financials so that your cost plans coincide with the costs of the project. This includes materials, labor and overhead.

- Material optimization in millwork: If you get the materials taken care of, this means that you can order exactly what you need, saving money while staying responsible environmentally. If contractors can figure out exactly what they need in materials, they can reduce the waste too.

- Quality control: Accurate estimates get you the right materials for the job, leading to better craftsmanship. For example, in building a cabinet, accurate cabinet material estimation means that you will be able to purchase the right quality and quantity of the materials for the cabinet.

- Project efficiency: Not having to deal with delays caused by not getting the materials correct or making errors in the estimating processes is a huge plus. If you have an accurate custom millwork BOM (Bill of Materials), you can ensure you have what is needed, keeping the project on pace.

The key steps in millwork material calculation & estimation

1. Clear understanding of project requirements

To get a good understanding of what the project is about, one must review carefully the drawings, specifications and plans being submitted. As soon as possible, also obtain a breakdown of the furniture material specification, detailing the species of wood, type of finish and any other special treatment to be given.

This first record will help to tie the aims of the project with the ideas and expectations of the client, and the resources that are available for carrying out the work. It is also an excellent means to assure creation of an accurate estimate to fit the project.

2. Calculating material requirements

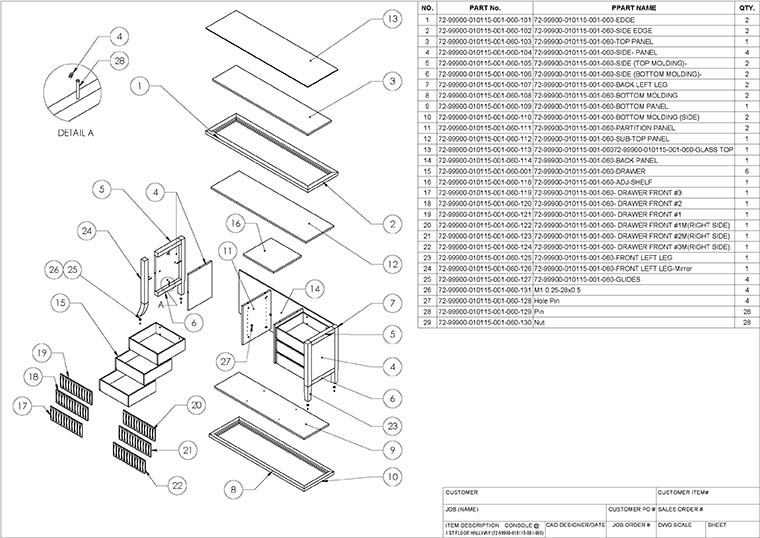

As soon as all measurements are in hand the next thing is to calculate how much material will be needed. This means preparing a millwork quantity takeoff clearly indicating nature of wood, hardware and fittings estimation, required adhesives, finishes, etc.

On preparing a list of materials, care must be taken to state clearly for each item its quantity and dimensions. Do not forget to add a waste factor of 5 to 10 percent which usually allows for cutting surplus and odd imperfections in the wood.

In furniture materials planning, do not omit taking into account the internal items, as well as the visible parts of the furniture. This will assist in getting the proper balance of strength and good looks.

3. Labor cost estimation

Labor cost estimation is calculated on the basis of the total number of hours of labor that the job will require and also the intricacy of the millwork. You can create a better labor estimate by using data from previous projects and expert evaluations. You should also take into account local labor rates and labor laws.

Simplify material planning for your millwork project with our expert estimates.

Get a quote »4. Accounting for overhead and additional costs

Overhead includes machinery depreciation, costs for storage, freight and related expenses. All such factors should be taken into account in order to be realistic in establishing budgets. Additional charges for equipment rental, safety, etc. and compliance with local regulations should also be included.

5. Final cost consultation

The final aspect of millwork cost estimation comprises compiling all the cost estimates, materials, labor, overhead and profit markup. This costing analysis will bring about a financially viable project and will assist in establishing a realistic budget. It will serve as a basis for negotiation both with clients and subcontractors.

Benefits of outsourcing millwork material estimation services

The benefits of outsourcing millwork material estimating services are more than just savings. They give you an edge in the architectural millwork marketplace:

- Flexibility: Convert fixed overhead costs into variable project based costs, so you can surf the peaks and valleys of the market.

- Time zone advantage: Leverage offshore estimating teams to enable a 24 hours workday. Drawings submitted at end of day become bid ready documents the next morning – cutting 50-70% in design and bidding cycles.

- Regulatory compliance: Access to specialists that are up to speed on AWI and AWMAC standards, required codes and ADA requirements in order to ensure that your shop drawings are compliant from the start.

- Value engineering: Millwork takeoff services gives you expert insights with respect to material joinery specifications, construction techniques and substitute materials that maintain design intent, while eliminating waste and fabrication time.

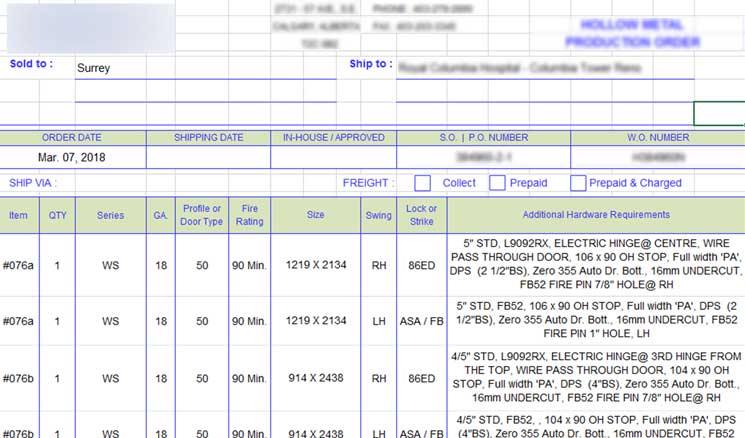

Detailed material take-offs for a door & frame manufacturer

A Canada based manufacturer of hollow metal and wooden doors, frames, windows and hardware was having difficulties with inconsistent estimating methodologies which resulted in errors and delays in bidding their custom architectural orders. They needed accurately profiled quantity take-offs.

TrueCADD’s team of experienced estimators scanned 2D architectural drawings and door and window schedules and compiled unit matrices for doors, frames, and hardware. We provided organized Excel files with material estimates. This allowed for quicker and accurate costing for manufacturing bids

The final deliverables resulted in:

- Faster feasibility studies and query resolution before quoting

- Less time required for estimating

- More customer quotes with higher accuracy

Material Estimates Manufacturer Door Frames

Material Estimates Manufacturer Door Frames

Get our precise millwork estimates tailored to your project.

Connect with us »Overcoming common challenges in material estimation

A number of challenges could arise during your interior millwork estimating such as inaccurate measuring, over ordering and hitting unforeseen site conditions and they can derail your project. They may be overcome as follows:

- Use advanced tools and technology: Utilizing digital tools for measuring, developing shop drawings and calculating material takeoff yields big savings. Using 3D for advanced visuals of ideas prior to building, precise measuring using laser measures, project management tools, will all create a true image of what you require.

- Detailed planning: Doing substantial digging into your project requirements and reviewing panel board measurement will prepare you for any problems for which you may be unprepared. Further, you must confer with your clients and reread project requirements before proceeding in order to create an accurate accounting.

- Continuous evaluation: Maintaining properly updated quotes during the project and changing them as events transpire helps to arrive at better final estimations. You must continually update estimates to track changes in project design or site conditions.

Why choose our millwork estimation services?

We help you with detailed and accurate millwork estimation which ensures that your project is both on schedule and on budget. We do this by providing a full range of services which include:

- Detailed assessment: We do a full assessment of the requirements of the project, the site conditions, the kind of materials that will be required. All these things considered make a great difference in the entire cost.

- Expert collaboration: We work with some of the most able craftsmen in the business and use the latest technology for our estimates. This gets your detailed, accurate and reliable estimates.

- Quality of work: We constantly strive to produce high quality in everything we do. We do not cut any corners in the matter of the material selection, or in any of the factors that affect the estimation process and ultimately your product.

Conclusion

If you want your projects to run smoothly, it is essential that you get your material estimation for millwork right. By establishing best practice, and consulting professional services, you can be sure that your projects will be well-managed, economical and of the highest quality. Investing a little time and effort into having accurate estimating systems in place is going to pay dividends all through the duration of the project, from the initial talks with the customer, to the final installation. Also by keeping up to date with the latest estimation technique, you will be ahead of the competition and provide top quality craftsmanship.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.