In the world of custom interiors, millwork and casework play crucial roles in defining both aesthetics and functionality. For manufacturers and interior designers, understanding these elements is essential, as each offers unique advantages in terms of customization, installation, and cost. This guide delves into the distinctions between millwork and casework, explores current design trends, and provides practical insights to help you choose the ideal solution for residential, commercial, and hospitality projects.

info@truecadd.com

Millwork vs. Casework: A Detailed Study of Differences and Comparison

Table of Contents

- Key Differences between Millwork and Casework

- What is Millwork?

- What is Casework?

- The Main Difference between Millwork and Casework

- Costing: Millwork vs Casework

- Casework or Millwork: Which is preferable?

- Essential Tools for Drafting and Modeling Millwork and Casework

- Use Case Scenarios: Where to Use Millwork vs. Casework

- Modern Trends in Millwork and Casework

- FAQs related to Millwork and Casework

- Bringing it all together

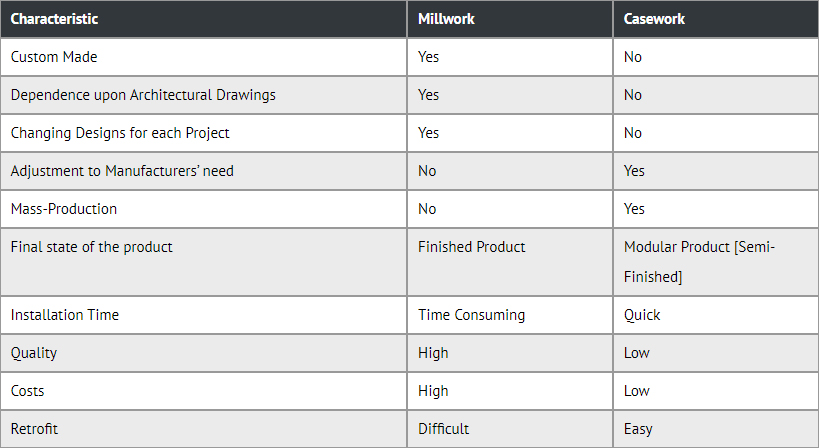

Key Differences between Millwork and Casework

| Criteria | Millwork | Casework |

|---|---|---|

| Customization | Highly customizable, tailored designs, finishes, and materials | Limited customization, often standardized with minor adjustments possible |

| Cost | Higher due to custom materials, skilled labor, and custom fitting | More budget-friendly, mass-produced with economical materials |

| Installation | Requires skilled, custom installation for precise fitting | Often pre-assembled, allowing easier and faster installation |

| Materials | Commonly high-quality wood, veneers, premium finishes | Typically MDF, laminates, or plywood for functional affordability |

| Ideal For | Permanent installations in luxury, aesthetic-focused spaces | Flexible spaces like offices or classrooms needing modular solutions |

What is Millwork?

Millwork refers to custom-fabricated woodwork crafted in specialized mills, creating architectural details that enhance a building’s interiors with both function and style. Products typically considered millwork include items like crown moldings, wall paneling, custom cabinetry, trim, stair banisters, and display counters, each designed to complement and elevate interior spaces.

Unlike structural elements like floors or ceilings, millwork items are decorative yet functional, often tailored to unique specifications. Crafted from high-quality materials, these pieces provide a bespoke look ideal for high-end residential and commercial projects where detail and precision are paramount.

Characteristics of Millwork:

- Customization: Tailored to specific sizes, materials, and finishes.

- Aesthetics: Adds a custom, high-end look to spaces.

- Installation: Requires skilled professionals for seamless integration.

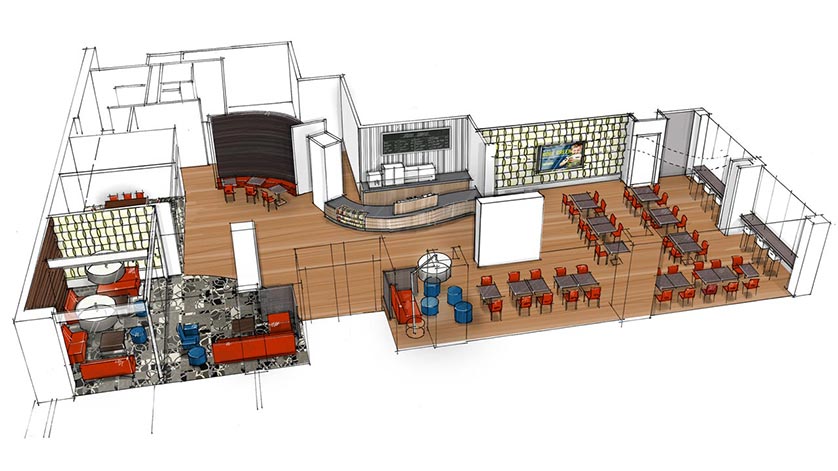

Millwork Drafting & Modeling for Restaurant

Millwork Drafting & Modeling for Restaurant

Millwork products are usually custom made and hence each design and manufacturing aspect of the product is engineered-to-order. Millwork design experts calculate the size requirements based on architectural floor plan drawings for designing geometry of millwork products. Customer’s choices are then factored in to finalize the millwork design and necessary details are added to develop detailed millwork shop drawings.

What is Casework?

Casework, in contrast, refers to factory-made wooden units such as cabinets (display and storage), racks & drawers, shelving, bookcases, storage spaces, etc. These items are often pre-assembled or easy to assemble, making casework more affordable and versatile in terms of installation. Casework tends to be less customizable than millwork, offering more standardized options suitable for offices, classrooms, and budget-conscious projects where functionality is prioritized.

Kitchen cabinets can fall under both millwork and casework. But since they are more often custom made and deep embedded within the building architecture are referred to as kitchen millwork. It includes every storage cupboard, pantry furniture and drawers.

Characteristics of Casework:

- Standardization: Manufactured in standard sizes, ideal for modular layouts.

- Affordability: Cost-effective due to mass production and economical materials.

- Installation: Quick and often simple, making it ideal for DIY projects or large-scale installations.

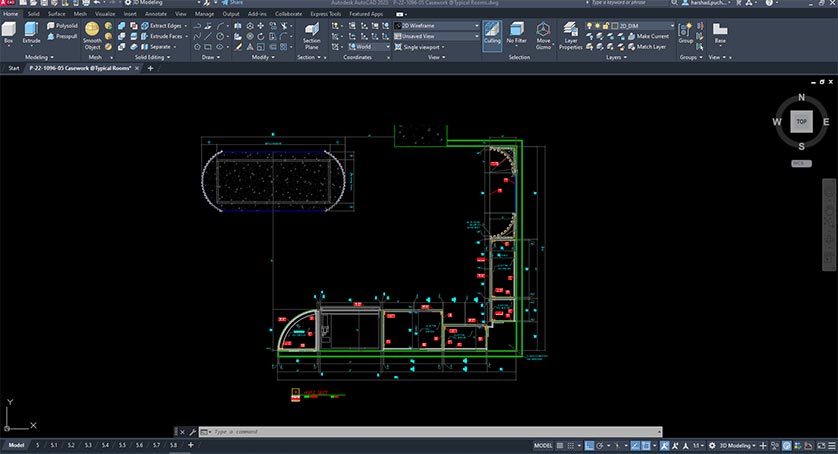

Casework Drawings in AutoCAD

Casework Drawings in AutoCAD

Ideally, casework construction doesn’t include furniture that is custom made and usually finds applications in modular usage. The central idea of any cabinet maker or other furniture manufacturing company (or the casework CAD drafters) is to deliver the pre-fabricated building products (or casework CAD shop drawings) that can be assembled at the site for the end product.

Speed Up Millwork Drafting with Autodesk Inventor

Struggling with slow millwork drafting? Discover quick tips to boost your efficiency with Autodesk Inventor.

Why Download?

- Efficiency Hacks: Streamline your drafting workflow.

- Advanced Features: Leverage Inventor’s powerful tools.

- Time-Saving Techniques: Reduce drafting time without sacrificing quality.

- Boost Productivity: Save time and increase efficiency.

- Stay Competitive: Enhance your drafting skills.

- Quality Assurance: Maintain high standards.

- Continuous Learning: Keep up with the latest techniques.

Discover the Secrets to Boost Your Productivity with Autodesk Inventor!

Grab Your Copy Today!The Main Difference between Millwork and Casework

Major difference between the two is that millwork is custom, while casework isn’t. Casework pieces are not made to fit the spaces, they are rather made after taking the specific geometrical dimensions of the space. There, of course, can be multiple variants and customization of colors, surface finish, etc. can be done at the end of the user in case of casework.

Now a question arises that are windows considered under casework or millwork? Ideally, windows, trims and etc. qualify as millwork as they are all custom made woodwork products. They are designed as per the need of the customer. So obviously manufacturers find it difficult to manufacture and deliver the final millwork product on time. But architectural millwork design drafting help drive efficiencies in highly custom millwork products.

L-Shape Kitchen in 2020 Design

L-Shape Kitchen in 2020 Design

Kitchen Drawing & Model in Cabinet Vision

Kitchen Drawing & Model in Cabinet Vision

Another difference lies in the method of production. Casework can be mass-produced, and hence is usually less expensive. Millwork, on the other hand, is only made for a specific space of the building and the same geometrical drawings cannot be reused for another project. Thus, millwork is relatively expensive.

Costing: Millwork vs Casework

Casework is simpler compared to millwork that is custom made and hence the latter is costlier. Clearly, the cost of per piece of millwork is higher but also offers better quality. It needs time and detailed attention of CAD drafters in deciding the space decoration, utility, and uniqueness.

Thus, it is extremely important that the quality of millwork shop drawings is of the highest standards which can be attained by partnering with millwork drafting service provider. Mantelpieces or armoire are the most appropriate examples of detailed carving and meticulous designing.

For smaller projects, customers usually tend to opt for casework as it allows picking up from the readily available factory products which are relatively available at affordable costs as against the custom made. But this also means that the final product quality may not be at par with the millwork products.

Thus, at first glance, it might seem that casework is not expensive, but evaluating the other parameters will lead to a conclusion that the architectural aesthetics available in molding and trim of room is unparalleled in millwork. It all boils down to the end customers’ project needs.

Speed Up Millwork Drafting with SolidWorks

Struggling with slow millwork drafting? Discover quick tips to boost your efficiency with SolidWorks.

Why Download?

- SolidWorks Shortcuts: Learn key shortcuts to save time.

- Optimized Tools: Discover hidden features for better efficiency.

- Customization Tips: Customize your workspace for faster access.

- Drafting Best Practices: Implement best practices for higher quality.

- Real-Life Examples: See how professionals speed up their work.

- Error Reduction: Techniques to minimize mistakes.

- Enhanced Collaboration: Tips for better team collaboration.

- Up-to-Date Methods: Stay current with the latest SolidWorks techniques.

Discover the Secrets to Boost Your Productivity with SolidWorks!

Grab Your Copy Today!Casework or Millwork: Which is preferable?

The above mentioned differences between millwork and casework, it is clear that both have their own set of advantages and disadvantages. Casework, falling under Division 12 of construction and millwork falling under Division 6 of construction are thus integral parts of any building construction project.

Casework, on one hand, provides consistent, quick storage options and comes for immediate use. It is very crucial in case of retail shops like food chain shops or restaurants. And for architectural millwork, it is convenient and allows customizing the CAD drawings as per the individual project needs. Mainly, it adds value and quality to the completeness of the project and thereby enhances the architectural space as a whole.

Since both, casework and millwork, have their own set of peculiarities, it is hard to say which one to undertake. One deciding factor could be how simplified the production shop floor activities can be with the final aim of cost reduction and utility. With this in mind, casework is modular and economical which makes it a more viable choice.

But from a customer’s perspective, casework is accommodating to the manufacturer’s product and millwork drafters’ ideas. Thus, if the customer’s want tailored designs, millwork is a better alternative. Millwork is also important while accounting for woodworking and bespoke furniture designing. Widely, CAD drawings for bespoke furniture manufacturing help furniture designers communicate design intent to the shop floor.

Essential Tools for Drafting and Modeling Millwork and Casework

- AutoCAD: Widely used for 2D drafting and 3D modeling, it offers specialized features for cabinetry design. Its capabilities allow for the creation of detailed millwork shop drawings and casework layouts, streamlining the design process for custom installations.

- SolidWorks: Excellent for 3D modeling and engineering drawings, especially when creating complex designs. It supports the development of detailed millwork models and casework assemblies, ensuring precision and facilitating the integration of parts in the overall design.

- Inventor: A powerful 3D CAD software for product design and engineering, ideal for creating detailed millwork and casework drawings, comprehensive 3D models, and precise Bill of Quantities (BOQ) and Bill of Materials (BOM).

- Cabinet Vision: Tailored for cabinet and millwork design, it includes features for creating layouts, production reports, and detailed drawings.

- Microvellum: Offers a comprehensive solution for designing, engineering, and manufacturing custom cabinetry and millwork.

- 2020 Design: A popular choice for kitchen and bath design, it provides tools for 3D modeling, layout planning, and material management specific to millwork and cabinetry.

- SWOOD: Integrates with SolidWorks, specializing in the design and manufacturing of wood products, providing tools for furniture and cabinetry design, along with nesting capabilities for efficient material use.

- Material Takeoff Software: Estimating Software like Bluebeam, PlanGrid, and Microsoft Excel etc. can help calculate the quantities and costs of materials needed for projects.

Use Case Scenarios: Where to Use Millwork vs. Casework

Understanding the ideal applications for millwork and casework can help determine the best choice for your project:

- Luxury Hotels and Hospitality: Millwork’s custom paneling and built-in furniture add a refined touch to guest rooms and lobbies. Casework is frequently used in back-of-house areas or offices where modularity and practicality are more important.

- Corporate Offices: Modular casework allows for easy reconfiguration to accommodate team expansions or relocations. Millwork might be used in executive offices or reception areas to create a polished look.

- Residential Kitchens: Millwork is ideal for custom kitchen cabinetry tailored to a specific layout. Casework is a more budget-friendly option for general-purpose cabinetry in apartments or smaller homes.

- Educational Institutions: Millwork provides durable custom solutions for libraries and auditoriums, while casework offers flexible and cost-effective storage for classrooms and administrative offices.

- Healthcare Facilities: Casework’s replaceable and modular design suits healthcare settings, where hygienic and adaptable furniture is essential. Millwork can be used in reception or lobby areas to create a welcoming environment.

Modern Trends in Millwork and Casework

In recent years, millwork and casework have evolved to incorporate sustainable and tech-friendly features.

Here’s a look at some of the latest trends shaping the industry:

- Sustainability: Growing awareness around environmental impact has led to a shift toward eco-friendly materials, including reclaimed wood, bamboo, and low-VOC finishes. This trend is particularly visible in millwork, where custom designs can incorporate sustainably sourced materials.

- Modular and Flexible Designs: Casework is increasingly designed for reconfigurability, meeting the demand for flexible office and residential spaces that can adapt over time.

- Tech Integration: High-end millwork now often incorporates features like hidden lighting, outlets, and smart home integration. For instance, custom cabinets may include built-in charging stations or lighting to enhance functionality.

- Minimalist and Scandinavian Influences: Clean lines, natural finishes, and soft colors have become popular across both millwork and casework, especially in modern residential and commercial spaces.

- Mixed Materials: Combining wood with metal, glass, or stone has gained popularity, particularly in millwork for a contemporary industrial aesthetic that works well in spaces like restaurants or high-end retail.

FAQs related to Millwork and Casework

-

Yes, millwork usually costs more due to the level of customization, premium materials, and skilled labor required. However, this investment can add long-term value to the space, especially in luxury settings.

-

While casework is mostly standardized, some manufacturers offer limited customization options, such as adjustments in size, finish, or hardware.

-

Millwork tends to be more durable because it’s crafted from high-quality materials and built to fit a specific space. However, casework made from good-quality MDF or plywood can also be quite durable.

-

Millwork often uses solid woods, veneers, and unique finishes, while casework typically relies on MDF, melamine, and laminates for affordability and functionality.

Bringing it all together

Now that you know the fundamental differences between millwork and casework, you can differentiate the two. Apart from the differences mentioned here, there are many more. Both, millwork and casework, find application in projects including commercial offices, retail stores, parks, hotels, shopping malls, restaurants, upholstery for furniture items, lightings, display counters, racks and shelves, mantelpieces etc. And hence they need to be designed with attention.

Custom Door Modeling and Designs

Custom Door Modeling and Designs

You as a millwork contractor, what matters the most is having architect, interior designer, home-builders, contractors and manufacturers on the same page during the project lifecycle. It is, thus, imperative for you to deliver millwork shop drawings with accuracy and correctness.

Outsourcing millwork shop drawings has proven to be profitable not just in terms of cost but also getting excellent quality, turnaround time and highly detailed documents. Through a close collaboration with external CAD drafting companies, millwork developers can reap the maximum benefits of outsourcing millwork shop drawings.

There are many CAD drafting companies that offer professional millwork and casework CAD drafting services to help you design custom CAD shop drawings. Building long term relationships with them help you get the best quality and display uniqueness of your space.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.