The furniture manufacturing process involves multiple stakeholders across stages, be it millwork, casework or bespoke furniture. CAD drawings effectively resolve resulting communication glitches, rework and delays by seamlessly connecting designers and the shop floor.

info@truecadd.com

CAD Drawings: Essentials for Millwork, Casework and Bespoke Furniture Manufacturing

Across the furniture manufacturing landscape, CAD drawing services form the foundation for engineering decisions made by architects, designers or manufacturers. High-quality and detailed manufacturing shop drawings prevent errors and engineering change notices.

Manufacturing drawings in CAD are more than mere graphical representation on paper of the products to be manufactured. They are essentially sets of technical information and instructions related to shape, size, location, tool path and tolerances, limits, allowances. Production drawings basically warehouse every piece of information needed for seamless machine operations. Given such detailed documentation, CAD drawings, unarguably are the pillars for manufacturing.

3 major application areas of CAD drawings in furniture manufacturing

1. Millwork shop drawings

The millwork industry needs precisely detailed CAD drafting for machine shop and production. Millwork CAD drafting service providers deliver custom furniture drawings, finishing details and engineering detailing with BOMs.

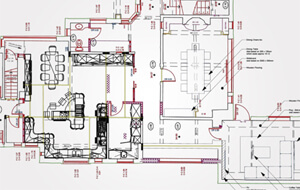

Millwork includes building components such as base, molding, trims, railing, stairs etc. for which shop drawings are closely interwoven with architectural plans. Ideally, all millwork shop drawings include details for manufacturing, assembly and construction of finished product using standard CAD drafting practices.

How millwork shop drawings benefit you:

-

Getting quick approvals

Millwork shop drawings establish a standard communication channel between the chief architect and the manufacturer. No matter how many times designs are revised, standard drawings will reflect the update changes and architects and designers sign them off before they are released for production.

-

Reduced reworks

Because of the detailed engineering information, millwork drawings reduce reworks, design change orders from shop floor and ensure uninterrupted manufacturing. Furthermore, with detailed millwork drafting, all divisions are in harmony with original design intent of the product and save overall manufacturing costs by reducing the waste.

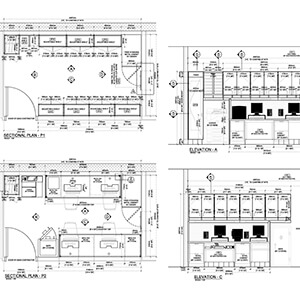

Joinery Shop Drawings from Architectural Plans for Office Floor, UK

At TrueCADD, millwork engineers resolved the acute challenges of coordination between designer, furniture manufacturer and contractors for a joinery design firm based in the UK.

The partnership focused on developing detailed millwork and joinery shop drawings needed across the architectural plans.

2. Casework shop drawings

For casework, it is said that proper planning and adequate detailing in drawings as per architectural plans can avoid poor performance and increase deliverable quality. By partnering with a CAD drafting expert for detailed casework drawings, you can avoid the costly reworks if not eliminate them completely.

For example, when the contractor or site engineers realize that the kitchen cabinets received from warehouse do not fit the spaces designed by architect it creates clutter on site. To avoid such mess, creating casework shop drawings with detailed limits and tolerances after in-depth study of architectural plans can help the manufacturers deliver what contractors expect.

How casework drawings impact your business:

-

Standard practice of communication

When casework shop drawings made as per standards such as AWI, NBKA, NFC etc., are introduced in design to manufacturing workflows they establish transparent design communication channel. The aim of cabinet drafters is to bring uniformity across all teams through casework shop drawings.

-

Conflict resolution

When multiple designers collaborate, design conflicts are obvious and it often results in dimensional discrepancies for end product. It can be seen in form of alcoves in walls or gaps in joineries and furniture. Such situations endlessly delay the project advancement until designs are redone and conflicts are resolved. Casework drawings or cabinet drafting hold all the details for manufacturing, assembly and installation/construction processes to ensure uninterrupted manufacturing.

Detailed museum casework drawings simplify design communication process

A furniture design and manufacturing firm partnered with TrueCADD to develop millwork and casework shop drawings from architectural plans for a museum. The firm faced challenges related to lack of communication between designers, manufacturers and the contractor.

The TrueCADD casework specialists prepared detailed casework drawings and documents like design process monitoring, project register and design change register. This resulted in:

- A seamless and simplified communication channel between stakeholders

- Accelerated design cycle

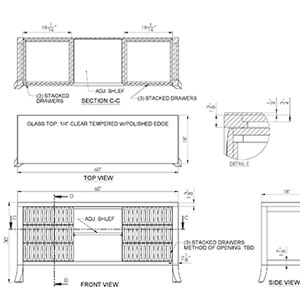

3. Bespoke furniture CAD drafting

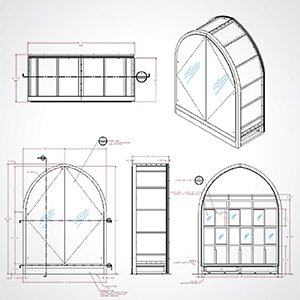

Bespoke furniture manufacturing is the most complex and high risk as far as profits are concerned. Developing furniture designs, getting them approved and drafting the final manufacturing drawing take the longest. In such a situation, errors in manufacturing or delays are clearly not affordable.

As a result, both, designers and manufacturers, rely on furniture CAD drafting experts. Unlike the previous two, furniture drawings demonstrate detailed study and construction drawings related to each small part of the assembly.

-

Collaborating with furniture drawing services provider

Bespoke furniture manufacturing drawings are developed from initial inputs such as rough sketches or pictures. CAD drafters prepare 2D and 3D CAD drawings from these which are then shared with the chief designer for approvals.

3D models are then creased using suitable CAD platforms such as SolidWorks or Inventor® and rendered for different purposes. Developing a comprehensive 3D CAD model and its photorealistic rendering creates a clearer design communication channel. The same model can be used by design and manufacturing teams as well as for preparing marketing collaterals with small modifications.

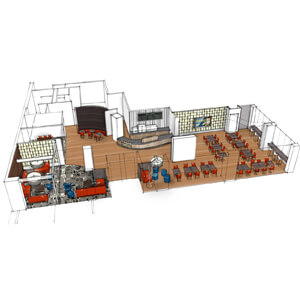

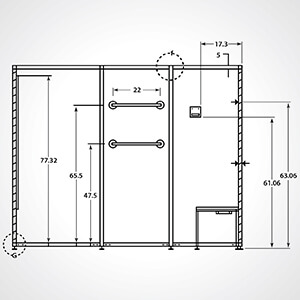

Retail store achieves significant cost reduction for its fitting room projects

TrueCADD furniture experts developed furniture drawings with meticulous assembly and installation guides for a retail store furniture manufacturers’ fitting room projects.

Close collaboration between the two teams and detailed study of hand sketches helped work around challenges of limited floor space availability and need for quick TAT.

The manufacturing drawings generated with BOMs resulted in:

- Reduction of design costs by 60%

- Inventory optimization by 30% due to modular design approach

- Reduction in transportation costs by 45% due to knockdown design approach

Read also: Millwork Shop Drawings for Appealing Designs of Retail Shops

Final words

To bring it all together, furniture manufacturing sector is a large industry with its specific demands and challenges. But what stays common for all the verticals is conveying the right design intent to shop floor through the medium of a CAD draft with appropriate amount of detailing and as per industry laid standards.

Whether you are a millwork developer, casework or a cabinet maker, or a bespoke furniture designer, your go to place is a standard CAD draft for transforming your design into a tangible profitable product.

Need help on an ongoing basis?

We establish long term business relationships with clients and are committed to total customer satisfaction.